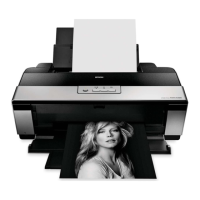

EPSON Stylus Photo R220/R230 Revision A

TROUBLESHOOTING Overview 8

1.1 Overview

This chapter describes how to identify troubles in two levels: unit level repair and

component level repair. Refer to the flowchart in this chapter to identify the defective

unit and perform component level repair if necessary. This chapter also explains motor

coil resistance, sensor specification and error indication.

Table 1-1. Troubleshooting Flowchart

Since CR Motor and APG Motor are DC Motors, the resistance among the electric

poles varies. Therefore, judge if it is normal or abnormal based on if there is no

operation of the motor or not; the resistance values cannot be used to judge the

abnormality. However, it is difficult to judge accurately, if it is not clear, replace the

motor.

START

UNIT-LEVEL TROUBLESHOOTING

UNIT REPAIR

ASSEMBLY AND ADJUSTMENT

END

Table 1-2. Motor, Coil Resistance

Motor Location Check Point Resistance

PF Motor Same as ASF/

Pump Motor

CN6

Pin1 and 3

Pin2 and 4

3.0Ω

±10%

(25°C/Phase)

Table 1-3. Sensor Check Point

Sensor Name Location Check Point Signal Level Switch Mode

PE Sensor CN9 Pin1 and 2

More than 2.4V

Off:

No Paper

Less than 0.4V

On:

Paper

PG Sensor CN14 Pin1 and 2

More than 2.4V

Off:

Anywhere of PG

Less than 0.4V

On:

In process of

switching PG

Star Wheel

Sensor

CN11 Pin1 and 2

-

On:

ASF Mode

-

Off:

CDR Mode

CDR Tray

Sensor

CN11 Pin3 and 4

-

Off:

No CDR Tray

-

On:

Detect CDR Tray

Loading...

Loading...