Setup & Operation 3. Environments and Installation

36 VT Rev.1

Be sure to transport and store the robot system in environments that meet the following

conditions:

Ambient relative humidity

10 % to 80 % (no condensation)

During unpacking and relocation, avoid applying external force to the arms and motors of

the Manipulator.

When the Manipulator is used for a robot system again after long-term storage, perform

a test run to verify that it works properly, and then operate it thoroughly.

When condensation occurs on the Manipulator during transport or storage, turn ON the

power only after the condensation dries.

3.8.2 Relocation

CAUTION

■

or relocate the Manipulator with two or more people.

ts are as follows. Be careful not to get hands,

fingers, or feet caught and/or

have equipment damage

d by a fall of the Manipulator.

VT6-A901* : Approx. 40 kg :89 lb.

(1) Turn OFF the power on all devices.

Remove the mechanical stops if using them to limit the motion range. For details

on the motion range, refer to Setup & Operation: 5.2 Motion Range Setting by

Mechanical Stops.

(2) Unscrew the anchor bolts. Then, remove the Manipulator from the base table.

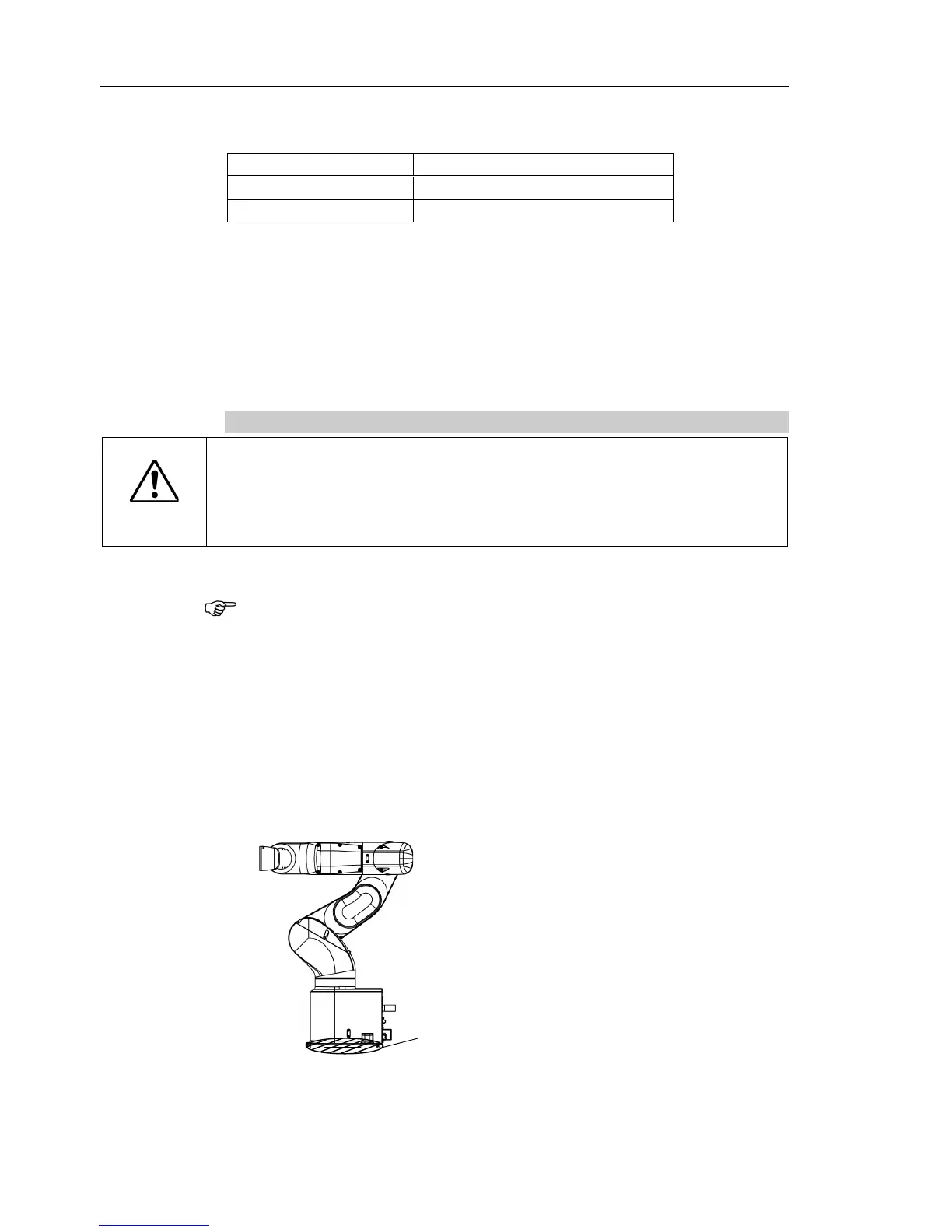

(3) Position the Manipulator as shown in the figure. Then, secure the Manipulator to

the delivery equipment or have at least 2 people to transport the Manipulator.

Recommend : Joint #2 +55 deg

Joint #3 −55 deg

Do not hold the bottom of the base (the shaded area in the figure). Holding the area

by hand is extremely hazardous and may cause your hands and fingers to be caught.

VT6

-A901* : Approx. 40 kg: 89 lb.

DO NOT hold the bottom of the base

by hand.

Loading...

Loading...