4 OPERATION

0449 165 160

- 18 -

© ESAB AB 2020

8.

Feed the wire forward 30 mm below the contact tip by pressing on the PEK.

9. Direct the wire by adjusting the knob (5).

NOTE!

Always use a guide tube (7) to ensure even feed of fine wire (1.6–2.5mm).

For MIG/MAG welding with wire sizes < 1.6mm, use a guide spiral, which is

inserted in the guide tube (7).

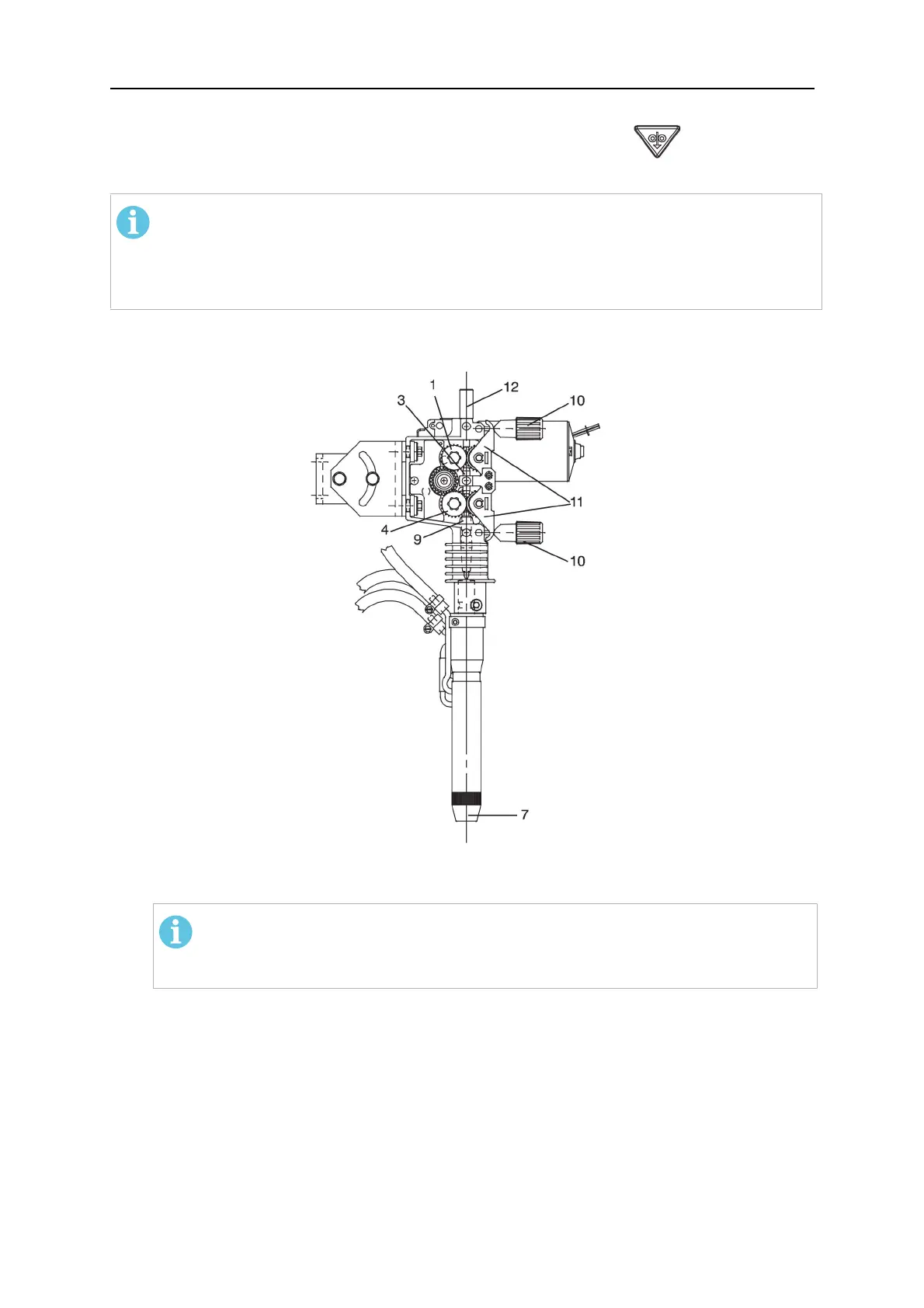

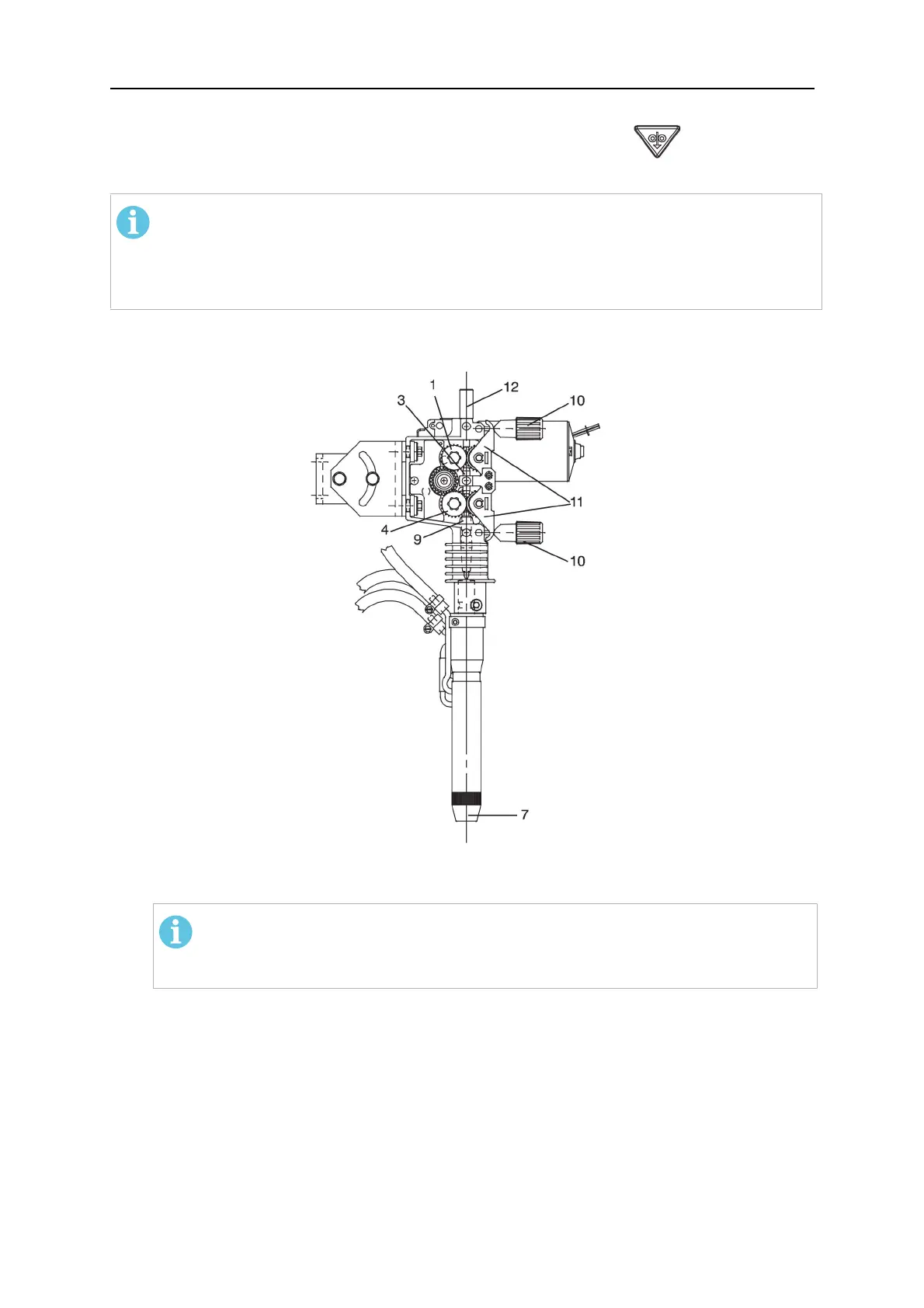

4.3 Loading the welding wire (A2TGJ14WD)

1. Check that the feed rollers (1, 4) and the contact nozzle (7) has the correct dimension

for the selected wire size.

NOTE!

The feed rollers are marked with their respective groove diameter (D) on the

opposite side of the roller.

2. Undo the pressure devices (10).

3. Put up the pressure arms (11).

4. Put the end of the wire through the wire guide nipple (12).

5. Locate the end of the wire in the feed roller (1) groove. Feed the wire through the

intermediate nozzle (3).

6. Locate the end of the wire in the other feed roller (4) groove. Feed the wire through

the outlet nozzle (9).

Loading...

Loading...