Do you have a question about the ESAB CUTMASTER 60i and is the answer not in the manual?

Highlights important information like notes, cautions, and warnings.

Details critical safety precautions for cutting, plasma arc, voltage, fumes, and training.

Outlines terms, conditions, and period for the product warranty.

Guidance on navigating and understanding the owner's manual.

Instructions for identifying and checking the received equipment.

Details on input power, output current, duty cycle, and cut capacity.

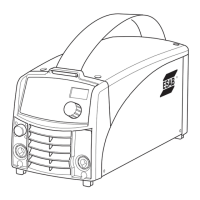

Requirements for connecting the power supply and overview of its components.

Covers manual and mechanized plasma torch types and their basic operation.

Details torch configurations, lengths, parts, and PIP circuit.

Procedure for quick torch connection and available accessories.

Basic introduction to plasma gas flow and cutting principles.

Safety guidelines for lifting and moving the power supply unit.

Procedures for accessing the switch cover and connecting primary power.

Steps for connecting the gas supply to the unit via the inlet port.

Instructions for installing optional single and two-stage air filter kits.

Guidelines for using high pressure air cylinders as the air supply.

Procedure for connecting the work lead to the power supply and workpiece.

Steps for connecting the torch to the power supply and checking air quality.

Instructions for mounting and aligning the mechanical torch assembly.

Detailed explanation of front panel controls, indicators, and their functions.

Steps required before starting operation, including power, torch, and air checks.

Guide to selecting cutting modes, setting current, and adjusting operating pressure.

Steps for performing cutting operations, including postflow and shutdown.

Guidance on selecting correct torch parts and factors affecting cut quality.

General cutting information, including cut quality characteristics and edge starting.

Detailed instructions for hand torch operation, including standoff and piercing.

Parameters and procedures for plasma arc gouging.

Procedures for operating the mechanized torch for cutting and piercing.

Tables providing recommended cutting speeds for various materials and conditions.

List of parts covered by US and foreign patents and pending patents.

Routine maintenance tasks and schedule for the power supply system.

Identification of common problems, causes, and basic troubleshooting steps.

A block diagram illustrating the sequence of operational steps.

Procedures for replacing basic parts like filter elements for the power supply.

Guidelines for cleaning and lubricating torch components for optimal performance.

Instructions for inspecting and replacing consumable parts of the plasma torch.

Overview of parts lists, return policy, and how to order replacement parts.

Lists replacement parts for the power supply, options, and accessories.

Lists external plastic replacement parts for the power supply unit.

Details replacement parts for hand torches and consumable parts for SL60 and SL100 torches.

Explanation of symbols and data found on the equipment's data tag.

Diagrams showing torch connector pin assignments and connection layouts.

Electrical schematic diagram for the 3-phase 400V CE units.

Record of manual revisions and changes made over time.

| Brand | ESAB |

|---|---|

| Model | CUTMASTER 60i |

| Category | Welding System |

| Language | English |