ESAB CUTMASTER 60i

OPERATION Manual 0-5488

4T-10

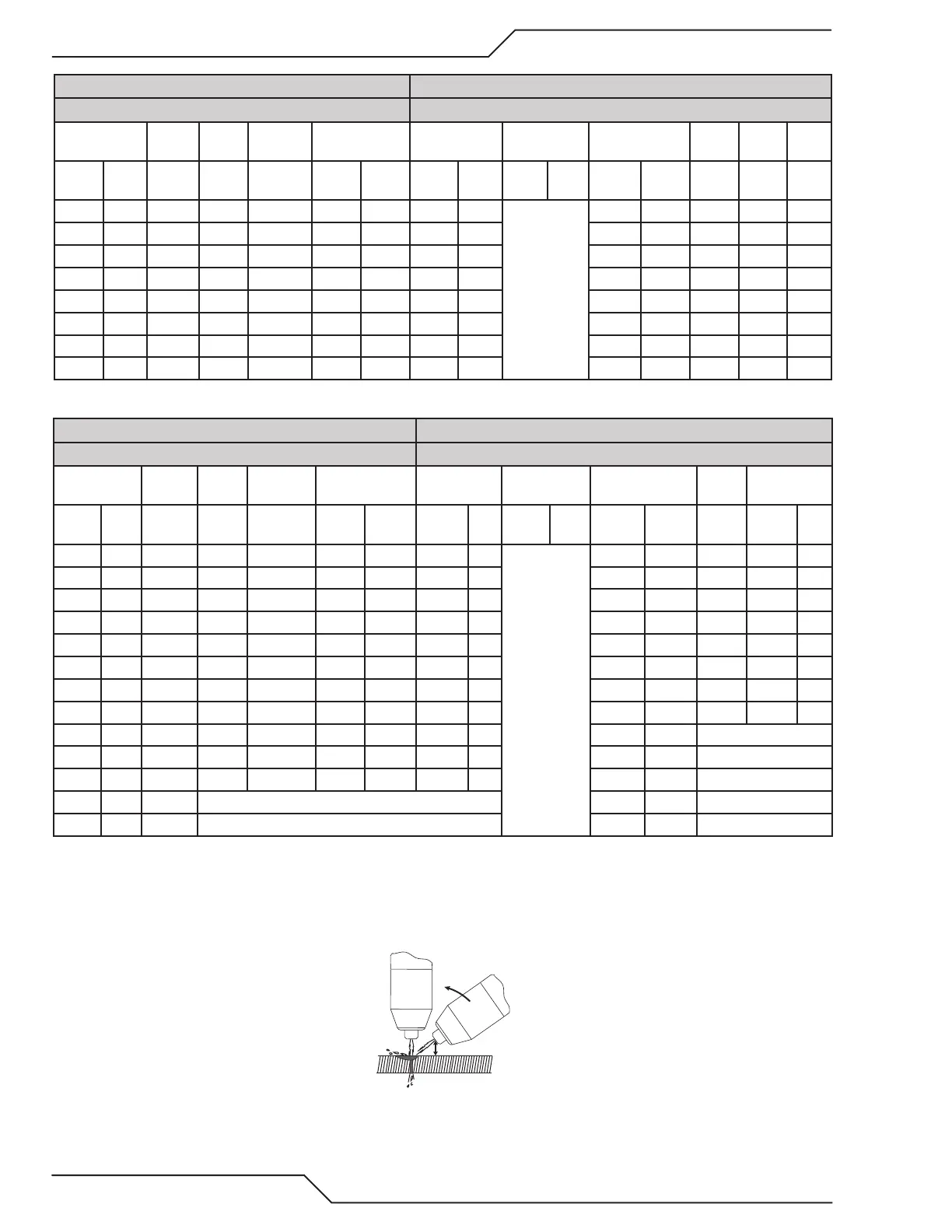

CutMaster® 60i With Exposed Tip Type Material: Aluminum

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per

Minute)

Standoff Plasma Gas

Pressure*

Flow (SCFH) Pierce Pierce

Height

Inches mm (Cat.

No.)

Volts

(VDC)

(Amps) Inches Meters Inches mm psi bar Plasma Total** Delay

(Sec)

Inches mm

0.032 0.8 9-8208 110 40 440 11.18 0.187 4.8

Set to the

central

region on

the pressure

dial. This is

illuminated

green when

selected.

55 170 0.00 0.2 5.1

0.051 1.3 9-8208 109 40 350 8.89 0.187 4.8 55 170 0.10 0.2 5.1

0.064 1.6 9-8208 112 40 250 6.35 0.187 4.8 55 170 0.10 0.2 5.1

0.079 2.0 9-8208 112 40 200 5.08 0.19 4.8 55 170 0.30 0.2 5.1

0.125 3.2 9-8208 118 40 100 2.54 0.19 4.8 55 170 0.40 0.2 5.1

0.188 4.8 9-8208 120 40 98 2.49 0.187 4.8 55 170 0.60 0.2 5.1

0.250 6.4 9-8208 123 40 50 1.27 0.187 4.8 55 170 1.00 0.2 5.1

0.375 9.5 9-8208 134 40 16 0.41 0.187 4.8 55 170 NR NR NR

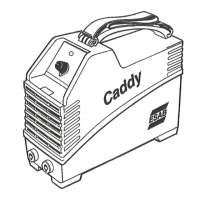

CutMaster® 60i With Exposed Tip Type Material: Mild Steel

Type Plasma Gas: Air Type Secondary Gas: Single Gas Torch

Thickness Tip Output Amperage Speed (Per

Minute)

Standoff Plasma Gas

Pressure*

Flow (SCFH) Pierce Pierce Height

Inches mm (Cat.

No.)

Volts

(VDC)

(Amps) Inches Meters Inches mm psi bar Plasma Total** Delay

(Sec)

Inches mm

0.060 1.5 9-8210 110 60 290 7.37 0.19 4.8

Set to the

central

region on

the pressure

dial. This is

illuminated

green when

selected.

90 245 0.00 0.19 4.8

0.075 1.9 9-8210 120 60 285 7.24 0.19 4.8 90 245 0.10 0.19 4.8

0.120 3.0 9-8210 120 60 180 4.57 0.19 4.8 90 245 0.10 0.19 4.8

0.135 3.4 9-8210 119 60 170 4.32 0.19 4.8 90 245 0.10 0.19 4.8

0.188 4.8 9-8210 121 60 100 2.54 0.19 4.8 90 245 0.20 0.19 4.8

0.250 6.4 9-8210 119 60 80 2.03 0.19 4.8 90 245 0.30 0.19 4.8

0.375 9.5 9-8210 124 60 50 1.27 0.19 4.8 90 245 0.50 0.19 4.8

0.500 12.7 9-8210 126 60 26 0.66 0.19 4.8 90 245 0.75 0.19 4.8

0.625 15.9 9-8210 127 60 19 0.48 0.19 4.8 90 245 Rolling Pierce

0.750 19.1 9-8210 134 60 14 0.36 0.19 4.8 90 245 Rolling Pierce

1.000 25.4 9-8210 140 60 6 0.15 0.19 4.8 90 245 Rolling Pierce

1.250 31.8 9-8210 NR, manual cutting only 90 245 NR

1.500 38.1 9-8210 NR, manual cutting only 90 245 NR

Rolling Pierce

A Rolling Pierce begins cutting with the torch head placed at an angle to the work surface. Splatter/dross are blown

away from the work area as the torch cuts. The torch head rotates towards vertical as the cut grows deeper and

pierces the workpiece.

Art # A-13353

Loading...

Loading...