EVCO S.p.A.

c-pro 3 nano CHIL | Application manual ver. 1.0 | Code 144CP3NCHE104

page 48 of 90

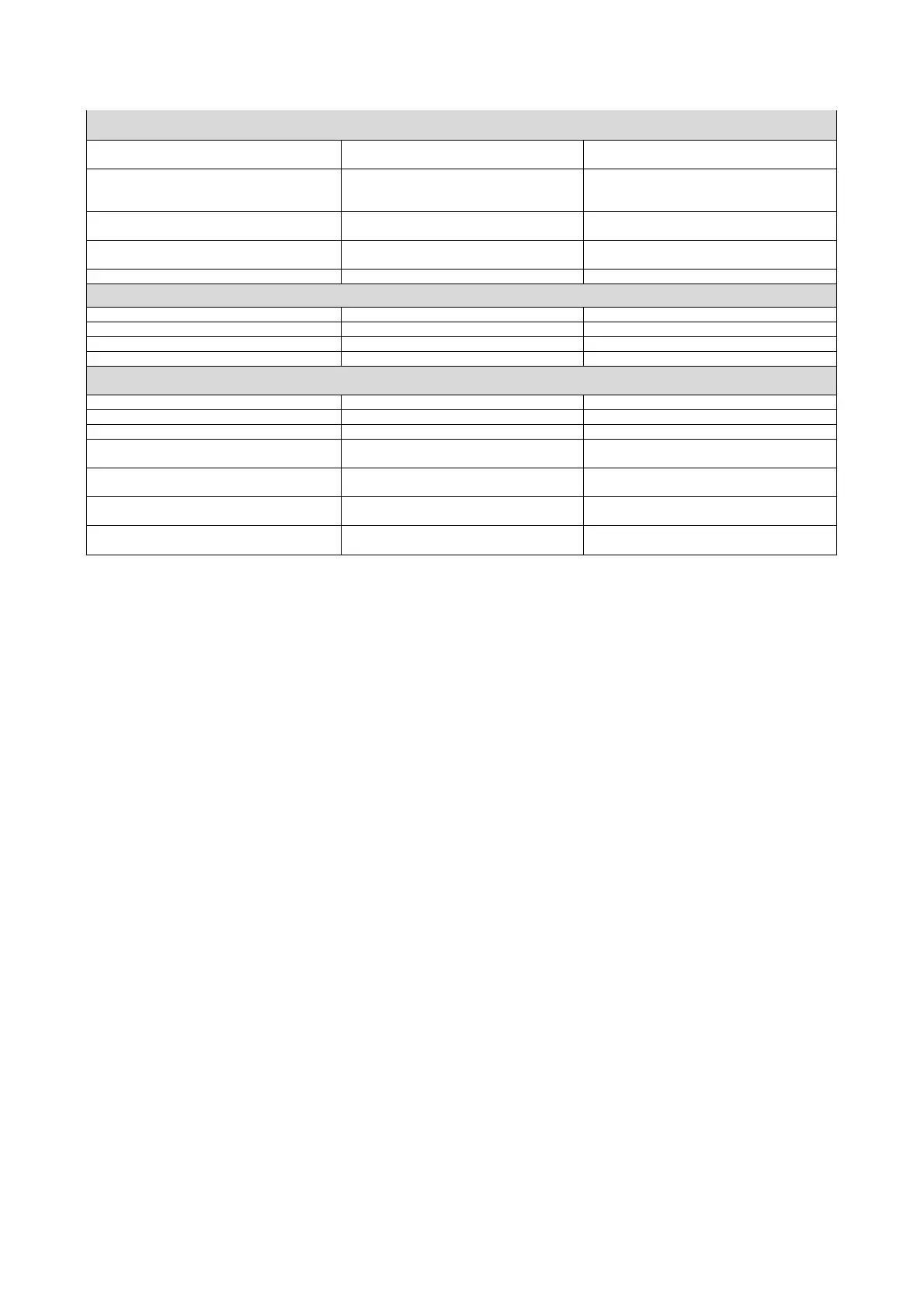

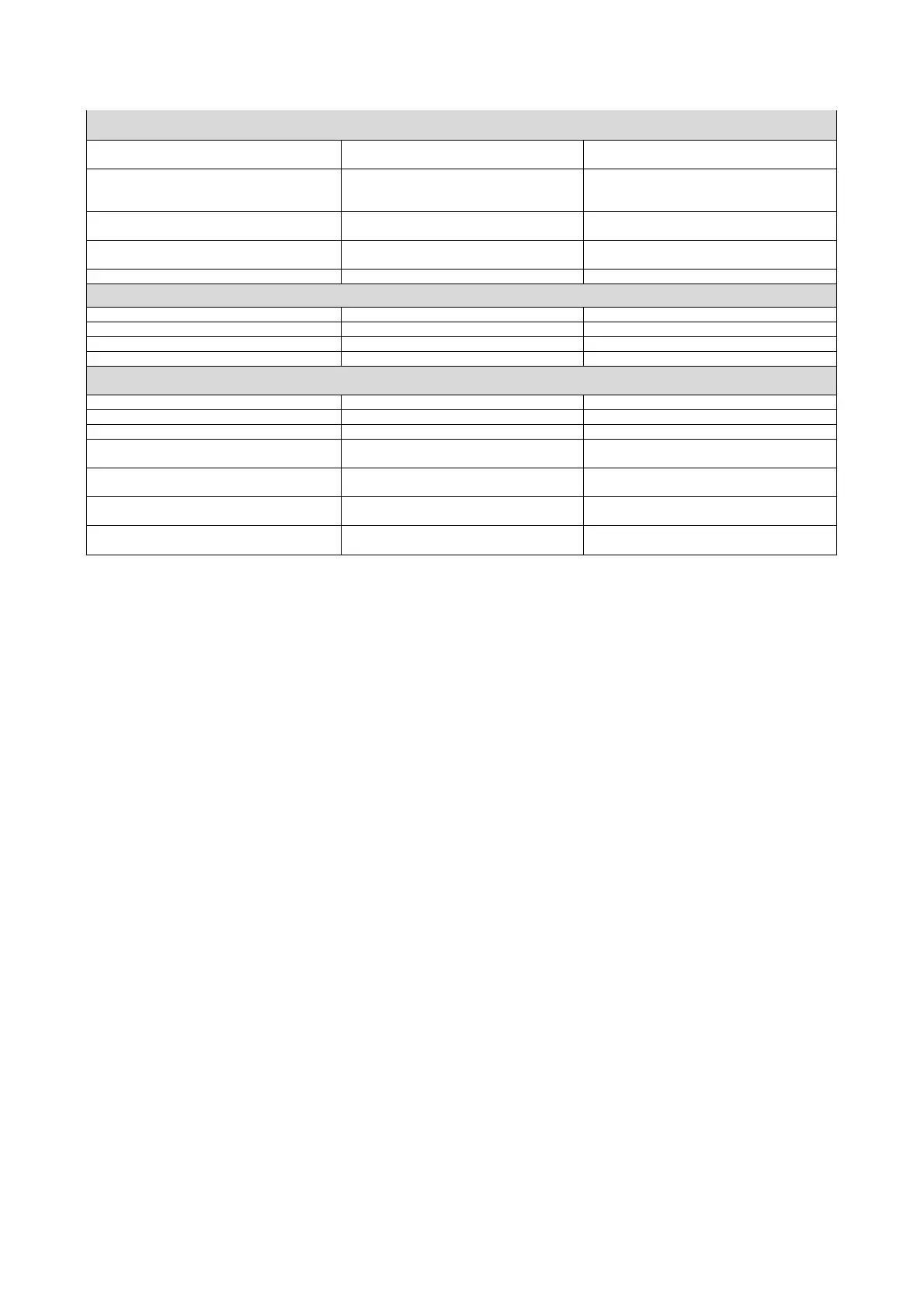

Digital Inputs Controller

D/I 1 On/Off Compressor thermal switch 2 (NC)

D/I 2 Heat sink exchanger flow switch (NC) Heat sink exchanger flow switch (NC)

D/I 3 Fan thermal switch C1 (NC) Fan thermal switch C1 (NC)

D/I 4 Low pressure C1 (NC) Low pressure C1 (NC)

D/I 5 High pressure C1 (NC) High pressure C1 (NC)

Analogue Outputs Controller

A/O 1 VentilationC1 (PWM) Single ventilation (PWM)

A/O 2 Not used Not used

A/O 3 Not used Not used

A/O 4 Not used Not used

Digital Outputs Controller

D/O 1 Pump 1 plant (NO) Pump 1 plant (NO)

D/O 2 Compressor 1 (NO) Compressor 1 (NO)

D/O 3 Not used Compressor 2 (NO)

D/O 4 Anti-freeze heater plant C1 (NO) Anti-freeze heater plant C1 (NO)

D/O 5 Ventilation C1 (Enable) (NO) Single ventilation (Enable) (NO)

D/O 6 Solenoid valve C1 (NO) Reversing valve C2 (NO)

D/O 7 Reversing valve C1 (NO) Reversing valve C1 (NO)

WARNING! When you change type of machine, it’s necessary to disconnect from the mains and then supply the tool with power again,

to allow the unit to correctly configure itself so that the board can assign all the relevant parameters. It is recommended to wait a few

seconds (three seconds are more than enough), before reconnecting the unit to the mains.

8.3 Configuration of the Circuits

If there is a dual circuit of the coolant (PG01=2), it’s necessary to set certain basic functions:

1. single or dual condensation unit (parameter PG11)

This configuration has an effect on:

• condenser control - in the event of a single fan, the control is based on maximum value of condenser

pressure/temperature.

• heat pump unit during defrost control – in the event of single fan, it’s not possible to perform defrost of each circuit

separately.

2. In the event of control of the ZERO ENERGY BAND (PC11=1), the control of the compressor is based on the average value of

the two output evaporation temperature probes. Using parameter PC02 you can select the distribution of the cooling steps

requested when you control the two compressor circuits:

a. PC02=0i 2 circuits are balanced

b. PC02=1saturates the steps of a circuit, before sending a request to the other.

3. If no compressors are in operation, the two evaporation temperature probes will decide which compressor circuit will start up

first

a. If mode=Cold(chiller), the circuit with the higher output evaporation temperature will start first

b. If mode=Hot(heat pump), the circuit with the lower output evaporation temperature will start first

4. Single or separate evaporation (PG12)

In the event of single evaporation (PG12=1), management, resistors and anti-freeze alarm are single. The control is

performed by reading the value of the highest temperature of the two output probes.

With single evaporation, the resistors and the antifreeze alarm activated are always those relative to the Circuit # 1, Circuit #

2 is not controlled.

Loading...

Loading...