141

ELECTRICAL AND IGNITION

FLYWHEEL AND STATOR SERVICING

7

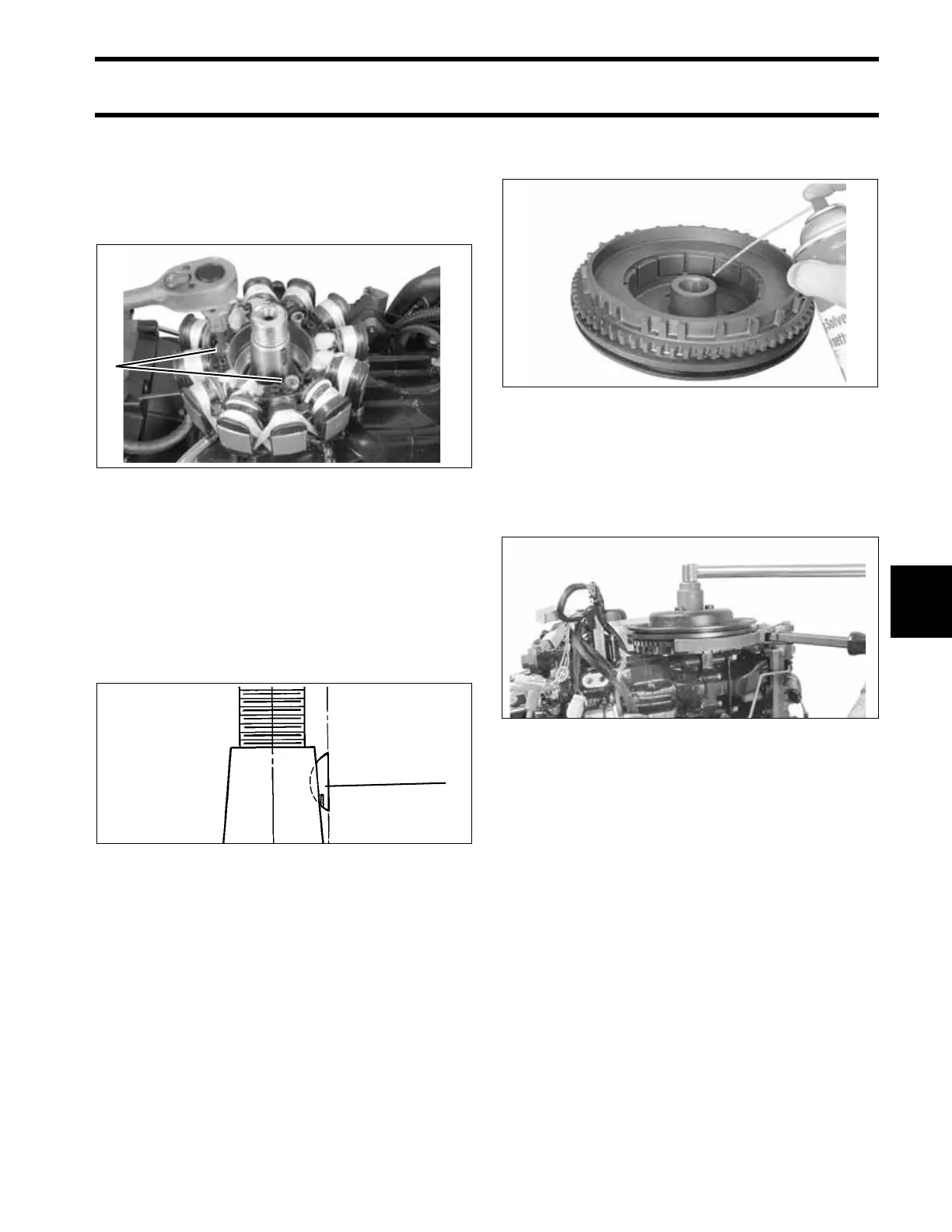

Stator Service

Disconnect stator harness connector.

Remove three allen head screws to remove sta-

tor.

To install stator, position stator on cylinder block.

Apply Nut Lock to screw threads. Install screws

and tighten in crossing pattern to a torque of 84 to

106 in. lbs. (9.5 to 12 N·m).

Flywheel Installation

Install the outer edge of flywheel key parallel with

centerline of crankshaft.

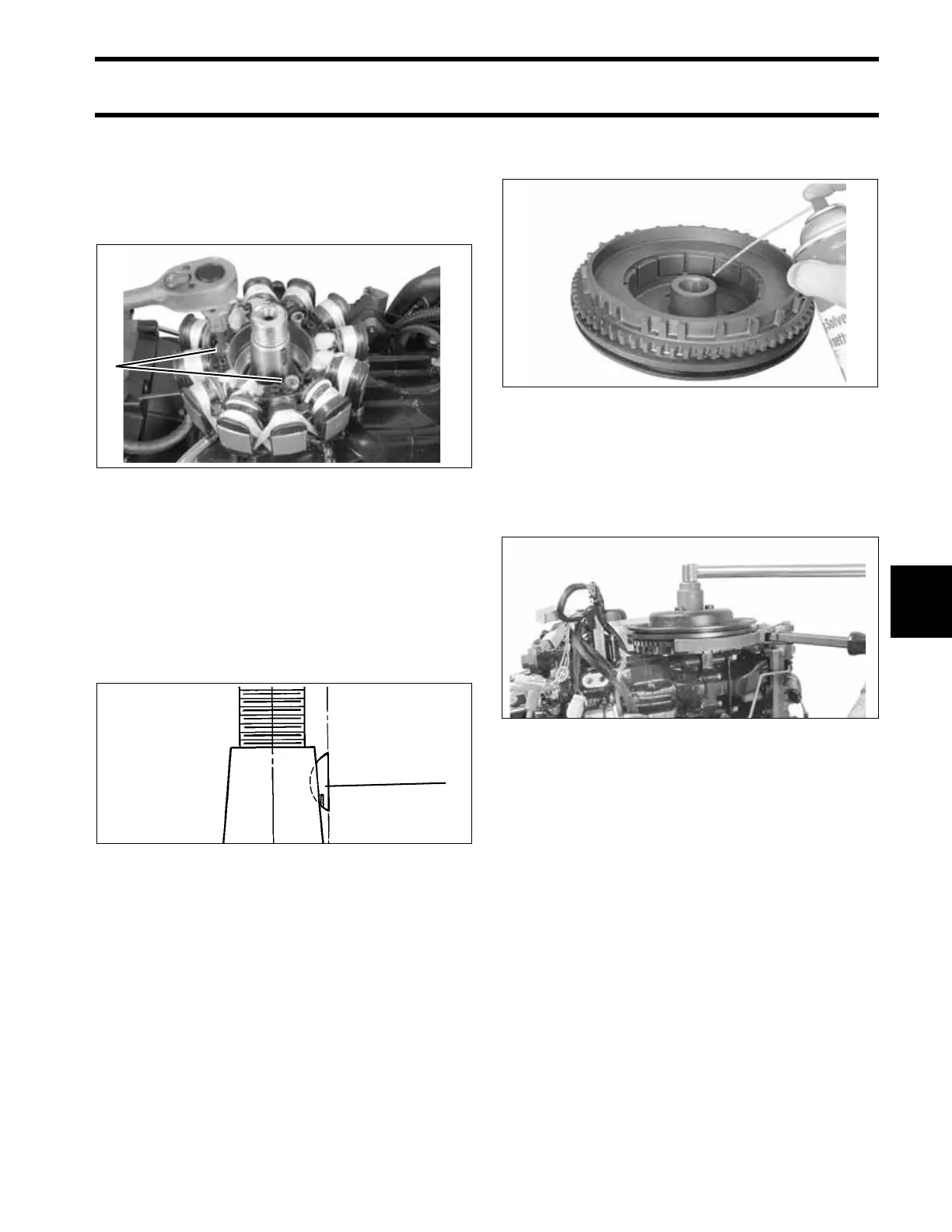

Thoroughly clean the crankshaft and flywheel

tapers with Cleaning Solvent

™ and let dry.

Align the flywheel keyway and install flywheel.

Coat the threads of a new flywheel nut with Triple-

Guard grease. Install the washer and nut and

tighten to a torque of 100 to 115 ft. lbs. (136 to

156 N·m).

Replace flywheel cover and recoil starter (rope

start models).

IMPORTANT: Check ignition timing after fly-

wheel removal or replacement. Refer to TIMING

ADJUSTMENTS on p. 142.

1. Stator screws 006486

1. Flywheel key DRC2116

1

1

002093

002090

Loading...

Loading...