290

TRIM AND TILT

ELECTRICAL CIRCUIT TESTS

ELECTRICAL CIRCUIT

TESTS

Relay Testing

When the trim-UP button is pressed, the UP relay

is energized and connects the blue trim motor wire

to the battery positive (+) terminal. The green trim

motor wire remains grounded. When the button is

released, the blue trim motor wire returns to a

grounded position.

When the trim-DOWN button is pressed, the

DOWN relay is energized and connects the green

trim motor wire to the battery positive (+) terminal.

The blue motor wire remains grounded. When the

button is released, the green trim motor wire

returns to a grounded position.

Refer to TILT/TRIM RELAY TEST on p. 135 for

relay testing procedure.

Trim and Tilt Motor Current Draw

Tests

Careful analysis of the electric motor's current

draw and trim/tilt unit operating speed aids evalu-

ation of the electric motor and certain mechanical

components.

Use a battery rated at 360 CCA (50 Ah) or higher

that is in good condition and fully charged to per-

form this test.

IMPORTANT: Specifications are for static

hydraulic tests. DO NOT attempt to perform the

following tests while the boat is moving.

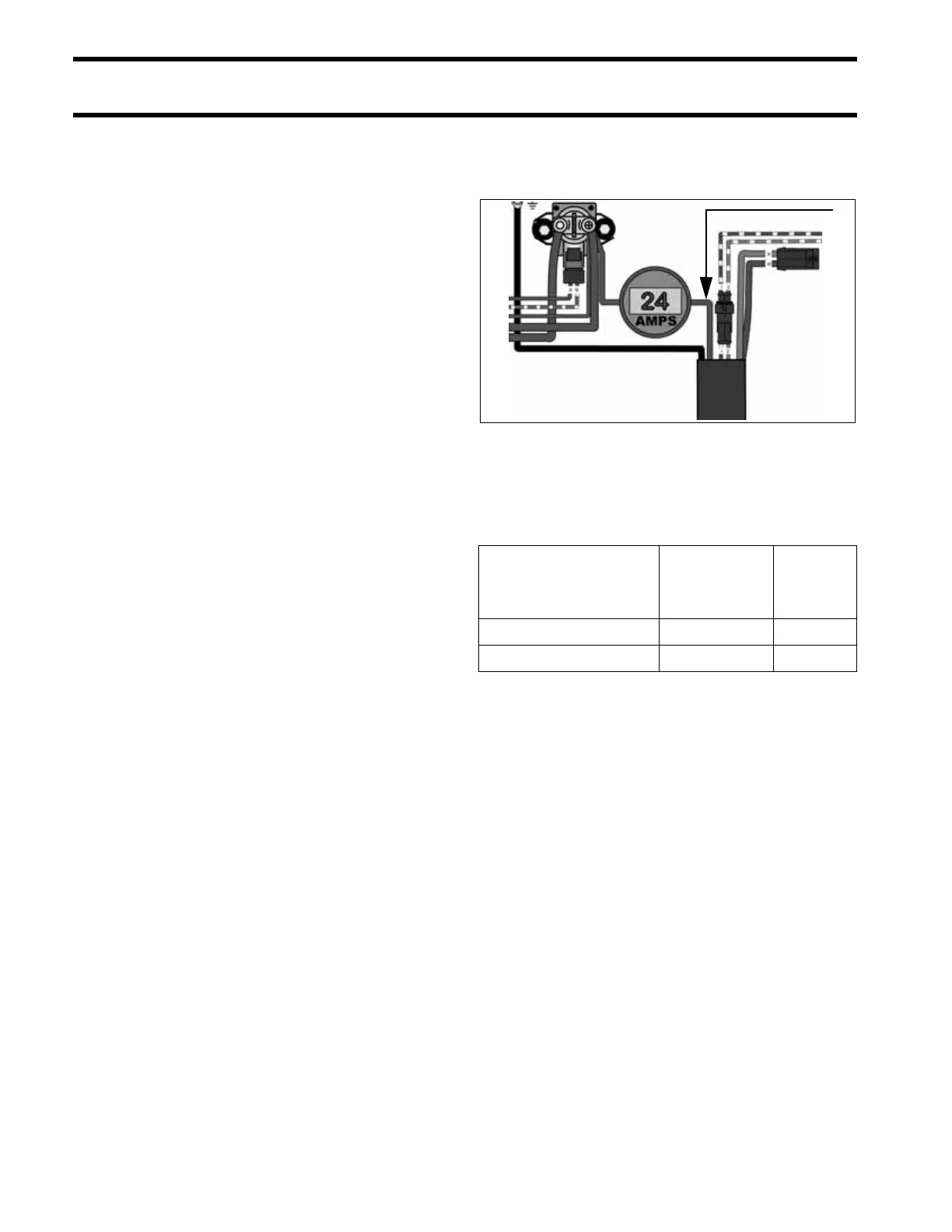

Connect a 0 to 100 A DC ammeter in series

between the battery side of the starter solenoid

and the red lead to the trim/tilt relay module.

Observe ammeter and a stopwatch while running

hydraulic unit through several complete cycles.

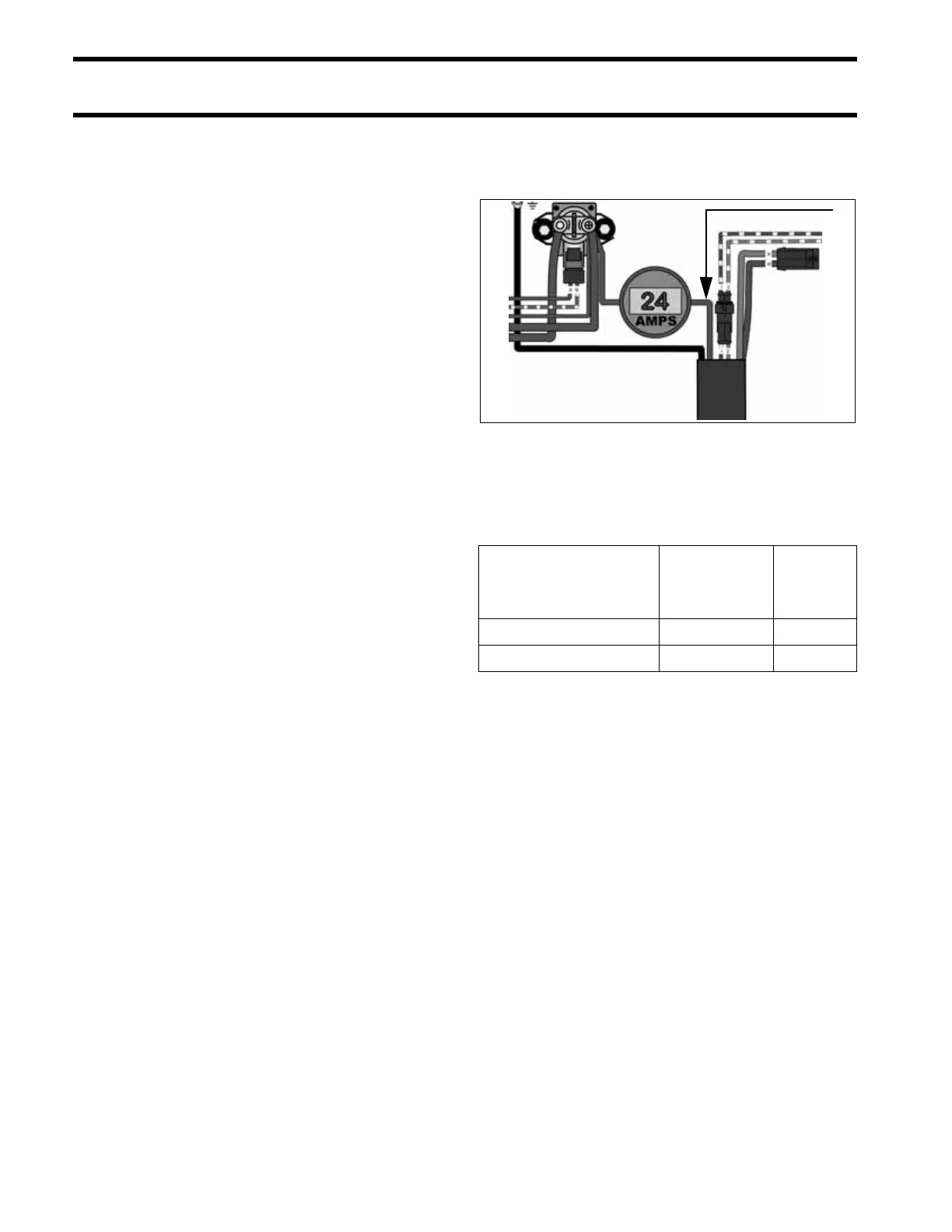

Compare test results to the values listed:

Test results include three basic possibilities:

A. Low current draw – Check for:

• Valves leaking

• Relief valve springs weak

• Pump damaged

• O-rings leaking

• Check valves fouled or damaged

• Manual release valve damaged

B. High current draw – Check for:

• Pump binding

• Motor binding

• Cylinder binding

• Valves sticking

C. Normal current draw, slow operating

speed – Check for:

• Impact valves damaged

• Check valve or shuttle valve malfunctioning

• Manual release valve damaged

1. Red lead 005441

Mode

Normal

Current Draw

Time in

Seconds

Full Range UP <30 A 12-18

Full Range DOWN <30 A <18

Stall <40 A –

1

Loading...

Loading...