217

POWERHEAD

POWERHEAD ASSEMBLY

11

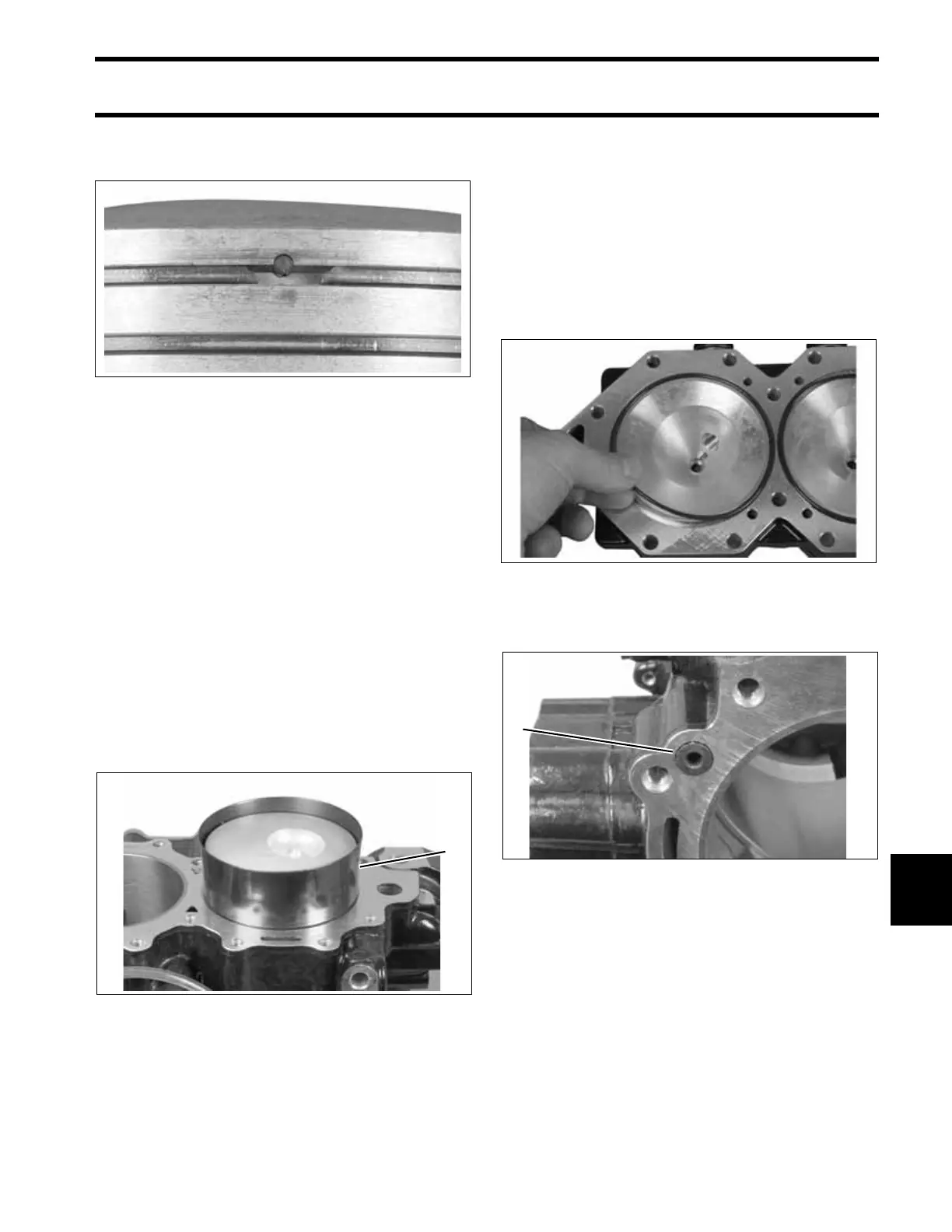

IMPORTANT: Be sure gap of ring fits squarely

around dowel pin.

IMPORTANT: Before continuing, make sure

that all Gel-Seal II has been removed from the cyl-

inder block and crankcase mating flanges. If

traces of hardened Gel-Seal II are left, main bear-

ings could be misaligned. Refer to CYLINDER

BLOCK CLEANING on p. 210.

Coat pistons, rings, cylinder walls, and Ring Com-

pressor, P/N 336314, with outboard lubricant.

Center connecting rod in piston and locate piston

rings on dowel pins. Place appropriate ring com-

pressor on piston.

Slide piston and rod assembly into the correct cyl-

inder, as marked during disassembly. Guide con-

necting rod through cylinder block to avoid

scratching cylinder wall.

Cylinder Head Installation

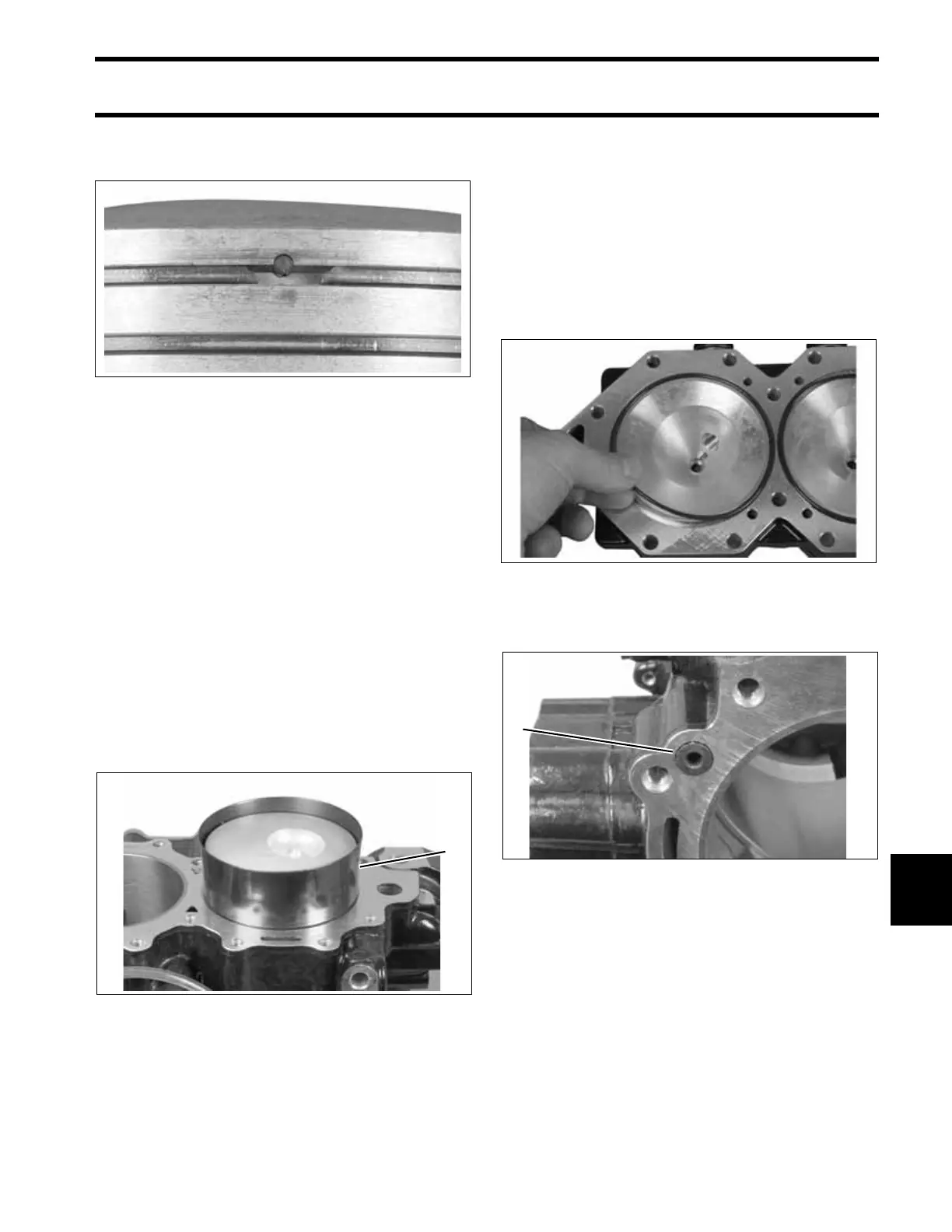

Install a new thermostat seal in cylinder head with

side marked “TO CYL HEAD” facing toward ther-

mostat.

Refer to THERMOSTAT SERVICING on p. 196

before installing cylinder head.

Lightly lubricate new cylinder head O-rings with

Triple-Guard grease and install in cylinder head.

Apply soapy water to water dam and insert into

block.

002048

1. Ring compressor 002059

1

002061

1. Water dam 002062

1

Loading...

Loading...