34000 Autry Street, Livonia, MI 48150 • 800.968.5530 • Fax 734.419.0209 • www.hamiltonengineering.com • LIT91127 REV 3/09

GAS CONNECTION/VENTING

H. GAS VALVE MAINTENANCE/REPLACEMENT

WARNING

Failure to follow all precautions could result in re, explosion or death!

DANGER

It is extremely important to follow these venting instructions carefully. Failure

to do so can cause sever personal injury, death or substantial property damage.

1) When checking or replacing a gas valve, the CO2 percentage in the ue gas is the preferred

measuring method to insure proper combustion and ring rate. CO is used as the alternate.

2) Gas valve replacement for the HW 599:

The left hand gas valve (which is normally factory-set and sealed and must not be adjusted) must be set up to

factory specications before any combustion related adjustments can be performed on the right hand valve. An

electronic manometer must be used, as it will be set to a scale of 0.01” WC.

The adjustment screw [1] (see Figure 3-3, page 11) normally used for setting maximum ow rate must be turned

counterclockwise until it begins to click when turned. The screw will not fall out, but will be fully retracted at this

point. this is for Natural Gas, for LP gas, close the left hand valve (clockwise) until it is closed down.

The digital manometer must now be connected to the outlet pressure tapping [4] on the left hand valve only

(marked do not adjust in gure 3-3, page 11), and the appliance red. It must be placed in the service mode and

held at the minimum ring rate (1653 rpm fan speed). With the appliance ring at this rate, adjust the offset

(minimum ring rate) screw [1] to a pressure of “0” +/- .0.01” WC. Be sure the manometer has been zeroed

out prior to making this setting.

Once this operation is complete, you may follow the instructions for setting the minimum and maximum ring rate

as shown in Sections G and H, for the right hand gas valve only.

Page 14 of 50

Please note: Venting system may contain one or more of the above materials.

The EVO is a direct vent appliance. The EVO is listed as a Category IV. Condensing Appliance.

PART 4. VENTING

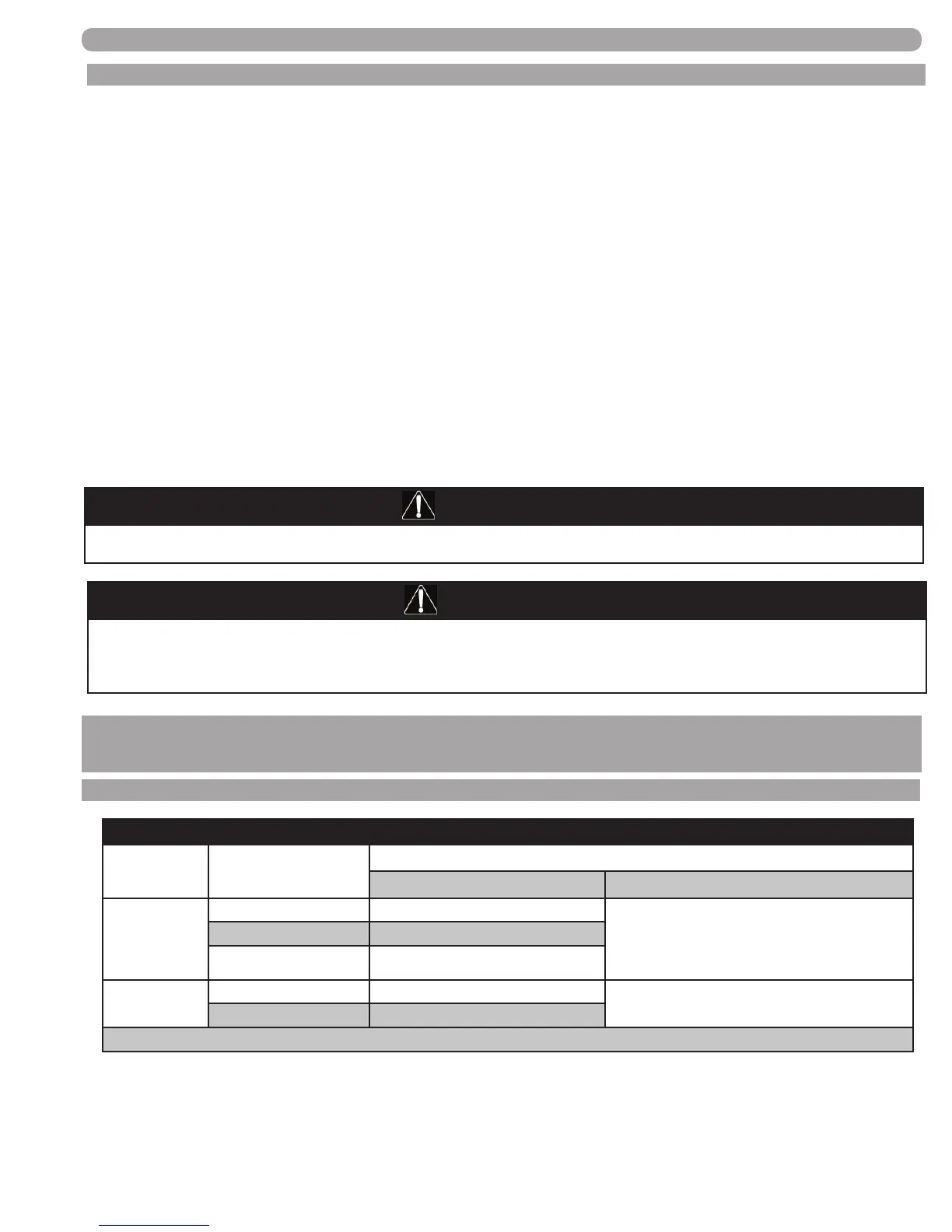

A. APPROVED VENTING MATERIALS

Item Material

United States Canada

Vent pipe

and

PVC schedule 40 ANSI/ASTM D1785 CPVC and PVC venting must be ULC-

S636 Certied. IPEX is an approved vent

manufacturer in Canada supplying vent

material listed to ULC-S636.

PVC - DVW ANSI/ASTM D 2665

CPVC schedule 40 ANSI/ASTM F441

Pipe cement

& primer

PVC ANSI/ASTM D2564

IPEX System 636

Cements & Primers

CPVC ANSI/ASTM F493

Loading...

Loading...