34000 Autry Street, Livonia, MI 48150 • 800.968.5530 • Fax 734.419.0209 • www.hamiltonengineering.com • LIT91127 REV 3/09

VENTING

Page 15 of 50

DANGER

It is extremely important to follow these venting instructions carefully. Failure

to do so can cause sever personal injury, death or substantial property damage.

WARNING

This vent system will operate with a positive pressure in the vent pipe. Do not

connect vent connectors serving appliances by natural draft into any portion of

mechanical draft systems operating under pressure.

Note: For concrete construction or to meet certain re codes, exhaust and inlet piping at the wall penetration to

the EVO must be CPVC Schedule 40 or 80 or stainless. The balance from the penetrated wall to the outside may

be PVC Schedule 40 or 80.

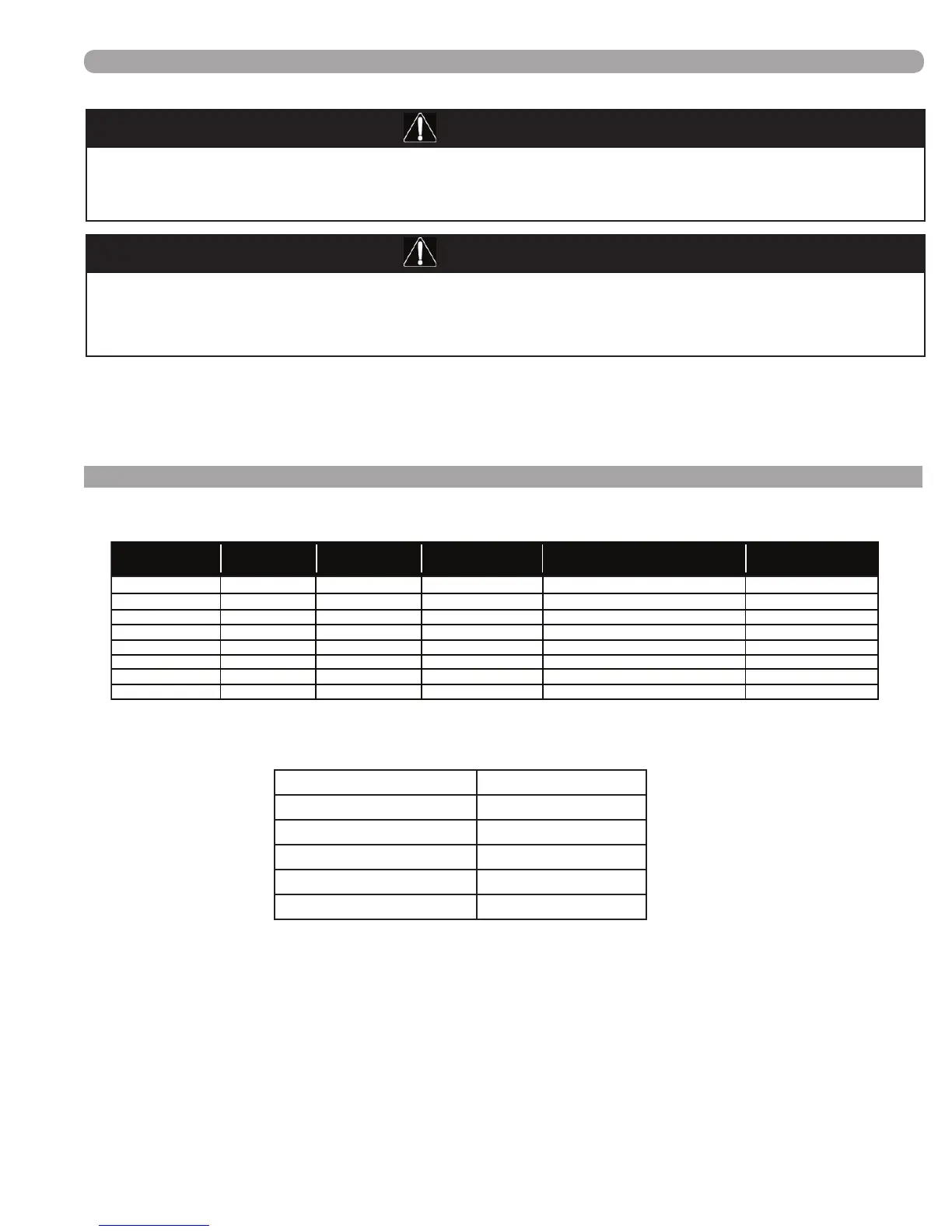

B. VENTING THE EVO

HW 79 3" Plastic Stainless 6' + (2) 90° elbows 225'

HW 129 3" Plastic Stainless 6' + (2) 90° elbows 200'

HW 199.1 3" Plastic Stainless 6' + (2) 90° elbows 100'

HW 179 3" Plastic Stainless 6' + (2) 90° elbows 200'

HW 299 4" Plastic Stainless 6' + (2) 90° elbows 3"=30' 4"=225'

HW 399 4" Plastic Stainless 6' + (2) 90° elbows 180'

HW 599 5" Stainless Plastic - 6”

* 6' + (2) 90° elbows 200'

Model

Vent

Diameter

Vent Type

Type

length

combined length

HW 199 3" Plastic Stainless 6' + (2) 90° elbows 95'

* The use of 6” PVC will require the purchase of a

special adapter from Hamilton Engineering, Inc.

(TABLE 4-1) VENTING SPECIFICATIONS

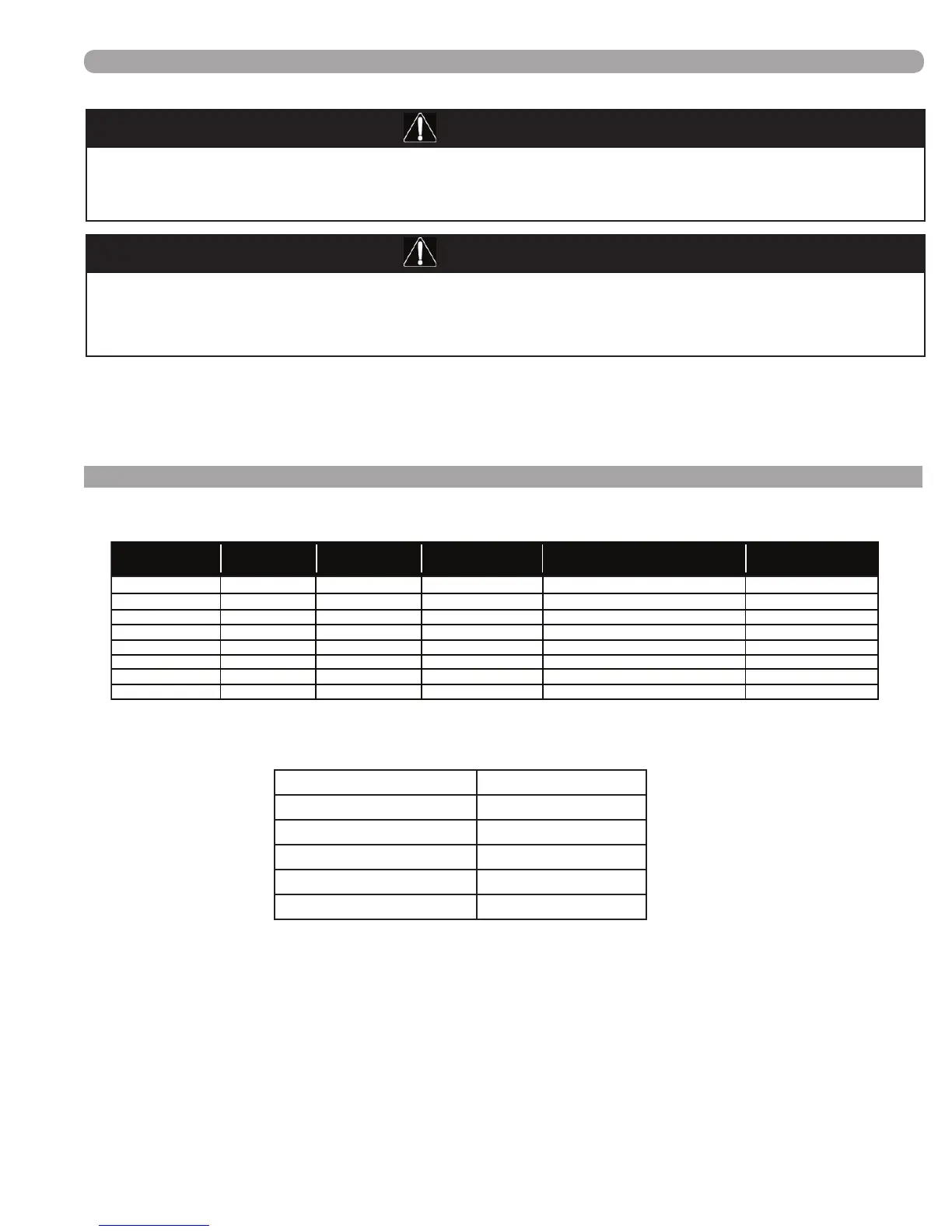

(TABLE 4-2) EQUIVALENT FEET

Fittings or Piping Equivalent Feet

90 degree elbow 5’

45 degree elbow 3’

Coupling 0

Air inlet elbow 6’

Exhaust coupling 1’

The inlet and exhaust pipes on the top of the cabinet should be the diameter and material indicated in the Venting

Specications Table above. It is very important that you plan the location properly to eliminate long pipe runs and

excessive ttings. Inlet pipe size must not be reduced. Do not combine the inlet air or exhaust with any other inlet

or exhaust pipe including either to an additional similar appliance, unless you have purchased an engineered

Common Venting System from Hamilton Engineering, Inc. The joints must be properly cleaned, primed and

cemented if plastic, and sealed per the manufacturer’s instructions if stainless. The piping must also be properly

supported as per Local and National Standard Plumbing Codes. It is important that the piping must be clean and

free from burrs, debris, ragged ends and particles of PVC (if applicable).

Loading...

Loading...