Design and function

MIG/MAG welding

099-005401-EW501

17.06.2014

5.7 MIG/MAG welding

5.7.1 Welding torch connection

Equipment damage due to improperly connected coolant lines!

If the coolant lines are not connected or a gas-cooled welding torch is used, the coolant

circuit is interrupted and equipment damage can occur.

• Connect all coolant lines correctly!

• When using a gas-cooled welding torch, add a tube bridge to the coolant circuit (see

chapter “Accessories”).

Fault with the wire guide!

On delivery, the central connector is fitted with a capillary tube for welding torches with

spiral guides. Conversion is necessary if a welding torch with a plastic core is used!

Welding torch with plastic core:

• use with guide tube!

Welding torch with spiral guide:

• use with capillary tube!

Depending on the wire electrode diameter or type, either a steel liner or plastic liner with the

correct inner diameter must be inserted in the torch!

Recommendation:

• Use a steel liner when welding hard, unalloyed wire electrodes (steel).

• Use a chrome nickel liner when welding hard, high-alloy wire electrodes (CrNi).

• Use a plastic core to weld or braze soft wire electrodes, high-alloy wire electrodes or aluminium

materials.

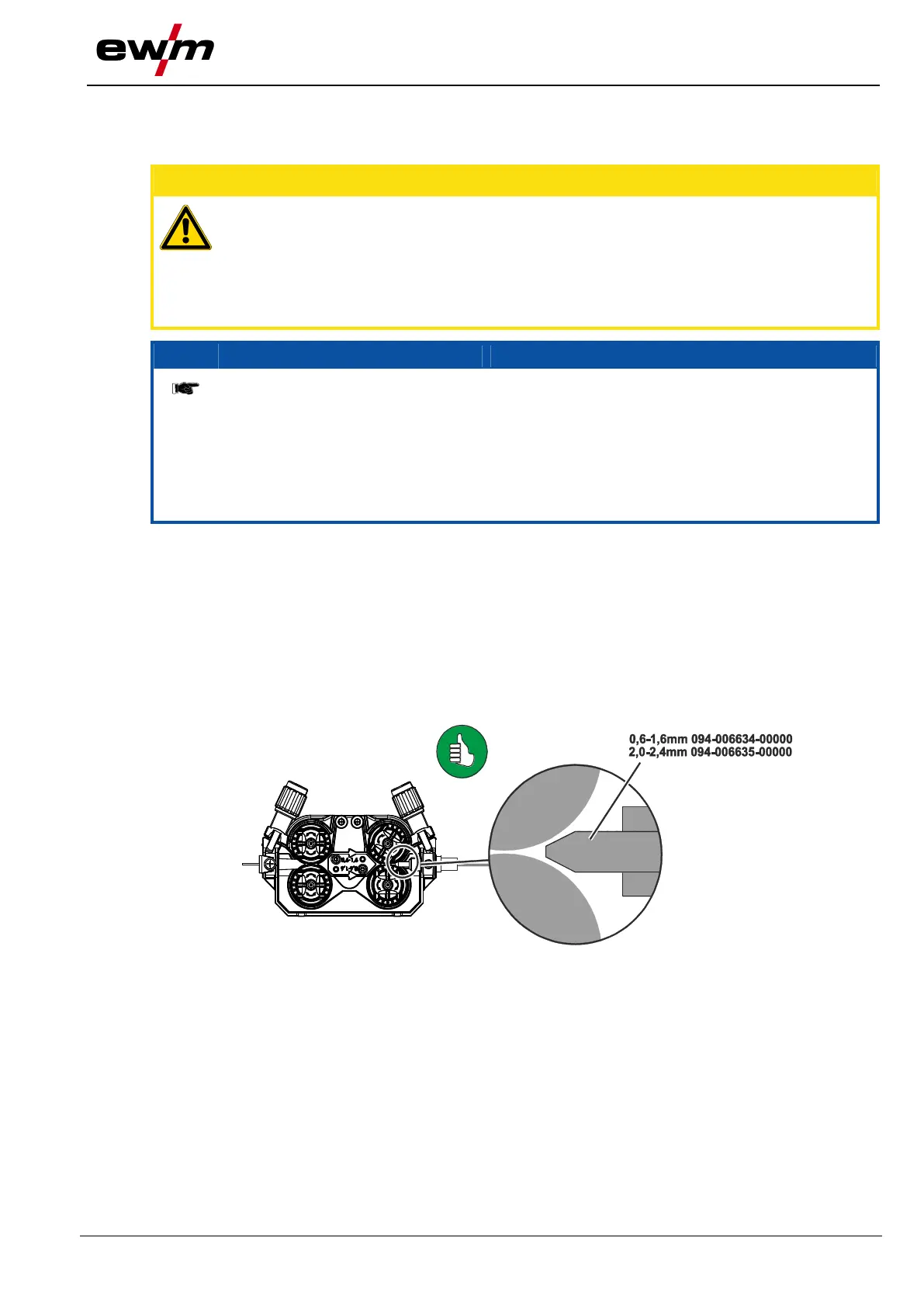

Preparation for connecting welding torches with a spiral guide:

• Check that the capillary tube is correctly positioned in relation to the central connector!

Figure 5-5

Loading...

Loading...