Design and function

MIG/MAG welding

099-005401-EW501

17.06.2014

5.7.2 Wire feed

5.7.2.1 Open the protective flap of the wire feeder

To perform the following steps, the protective flap of the wire feeder needs to be

opened. Make sure to close the protective flap again before starting to work.

• Unlock and open protective flap.

5.7.2.2 Inserting the wire spool

Risk of injury due to incorrectly secured wire spool.

If the wire spool is not secured properly, it may come loose from the wire spool holder

and fall to the ground, causing damage to the machine and injuries.

• Securely fasten the wire spool to the wire spool holder using the knurled nut.

• Before you start working, always check the wire spool is securely fastened.

Standard D300 wire spool holder can be used. Adapters (see accessories) are required

when using standardised basket coils (DIN 8559).

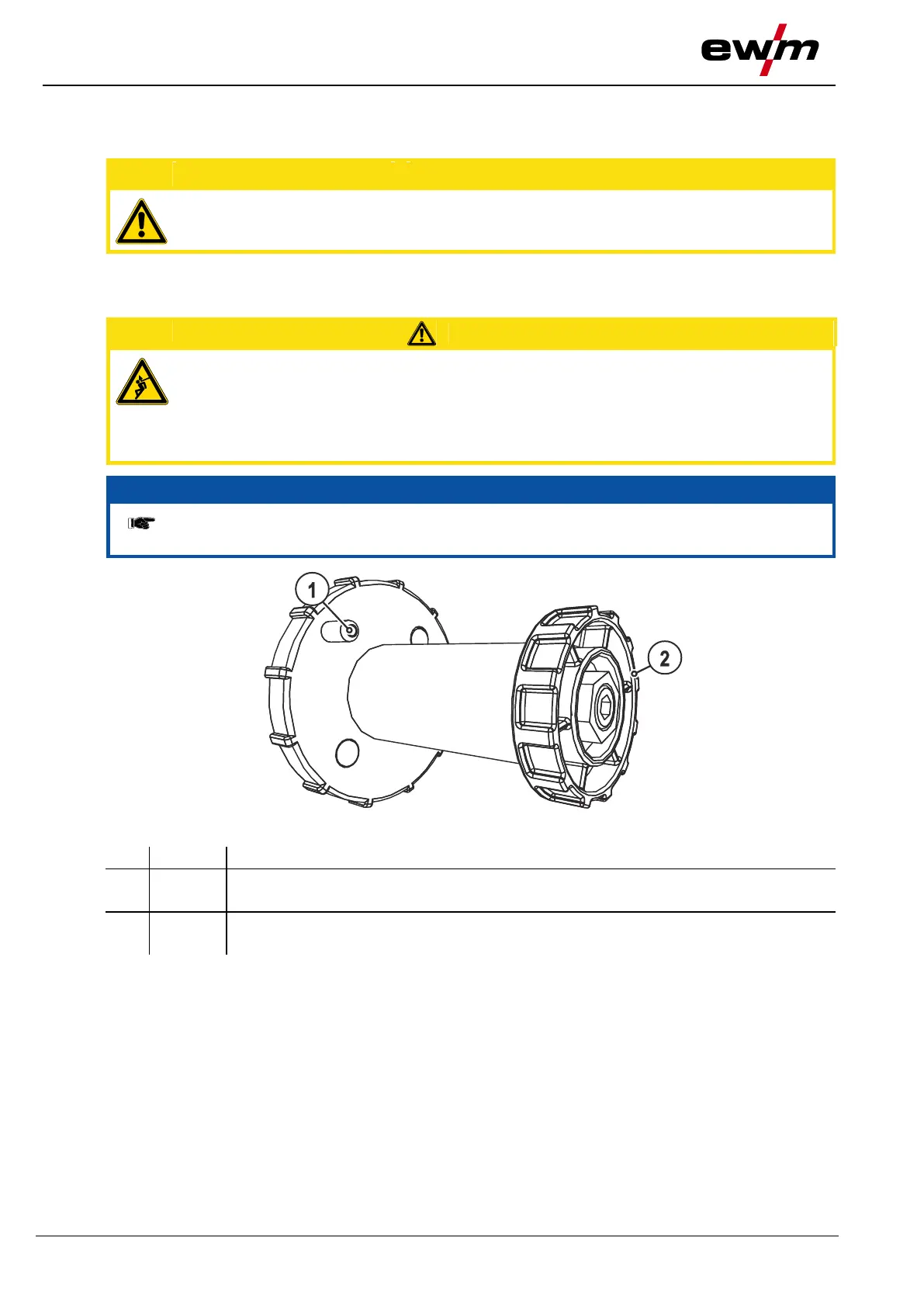

Figure 5-8

Carrier pin

For fixing the wire spool

Knurled nut

For fixing the wire spool

• Loosen knurled nut from spool holder.

• Fix welding wire reel onto the spool holder so that the carrier pin locks into the spool bore.

• Fasten wire spool using knurled nut.

Loading...

Loading...