Design and function

Transport and installation

099-007010-EW501

07.09.2016

Insufficient ventilation results in a reduction in performance and equipment damage.

• Observe the ambient conditions!

• Keep the cooling air inlet and outlet clear!

• Observe the minimum distance of 0.5 m from obstacles!

4.1.3 Workpiece lead, general

Risk of burning due to incorrect welding current connection!

If the welding current plugs (machine connections) are not locked or if the workpiece

connection is contaminated (paint, corrosion), these connections and leads can heat up

and cause burns when touched!

• Check welding current connections on a daily basis and lock by turning to the right when

necessary.

• Clean workpiece connection thoroughly and secure properly. Do not use structural parts of

the workpiece as welding current return lead!

4.1.4 Welding torch cooling system

4.1.4.1 Connection

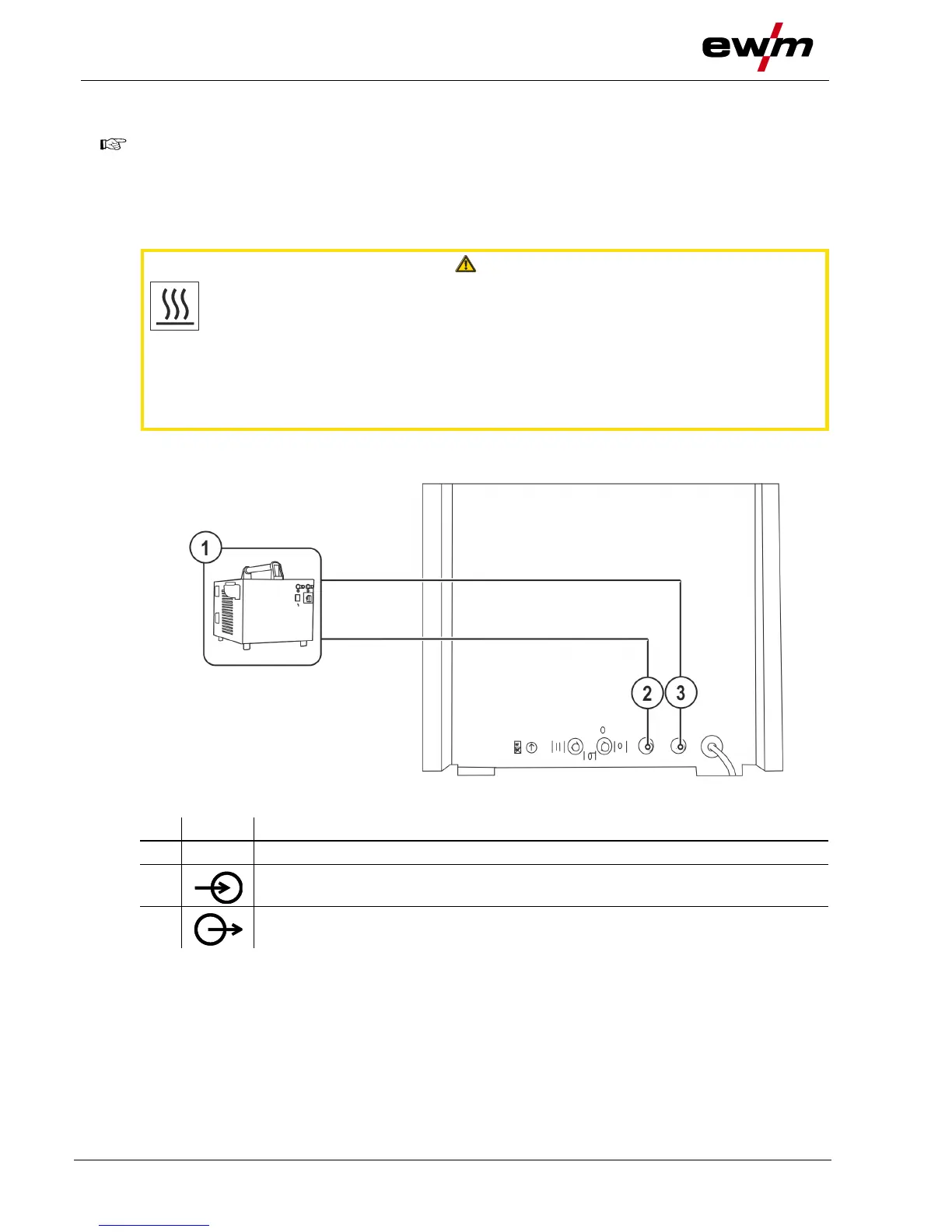

Figure 4-1

Welding torch cooling unit

Coolant return from the welding torch cooling unit

Coolant forward flow to the welding torch cooling unit

• Lock connecting nipples of the cooling water tubes into the corresponding quick connect couplings:

Return line red to quick connect coupling, red (coolant return) and

supply line blue to quick connect coupling, blue (coolant supply).

Loading...

Loading...