Design and function

Transport and installation

099-007010-EW501

07.09.2016

Before commissioning, the plasma welding torch must be equipped for the welding JOB and

correspondingly set/adjusted!

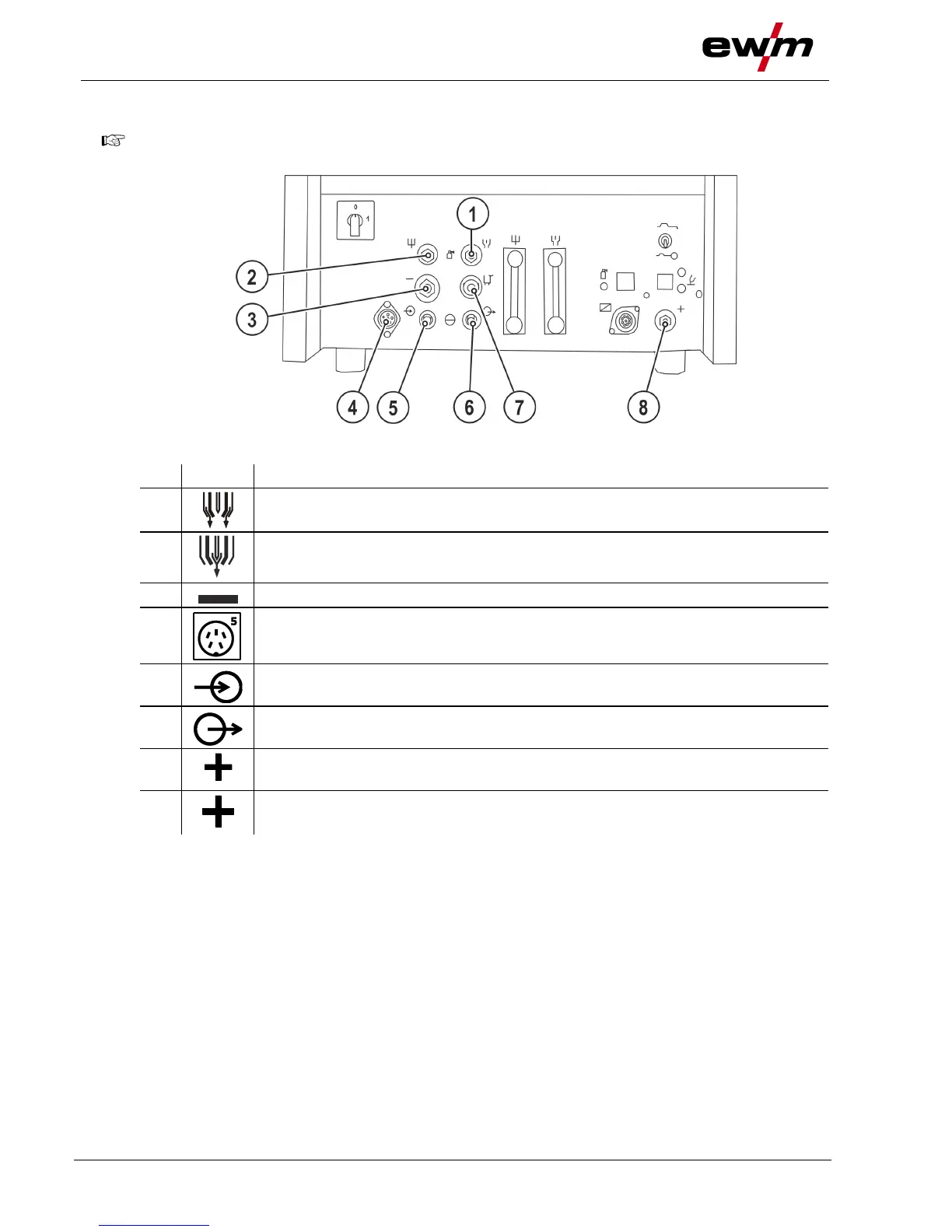

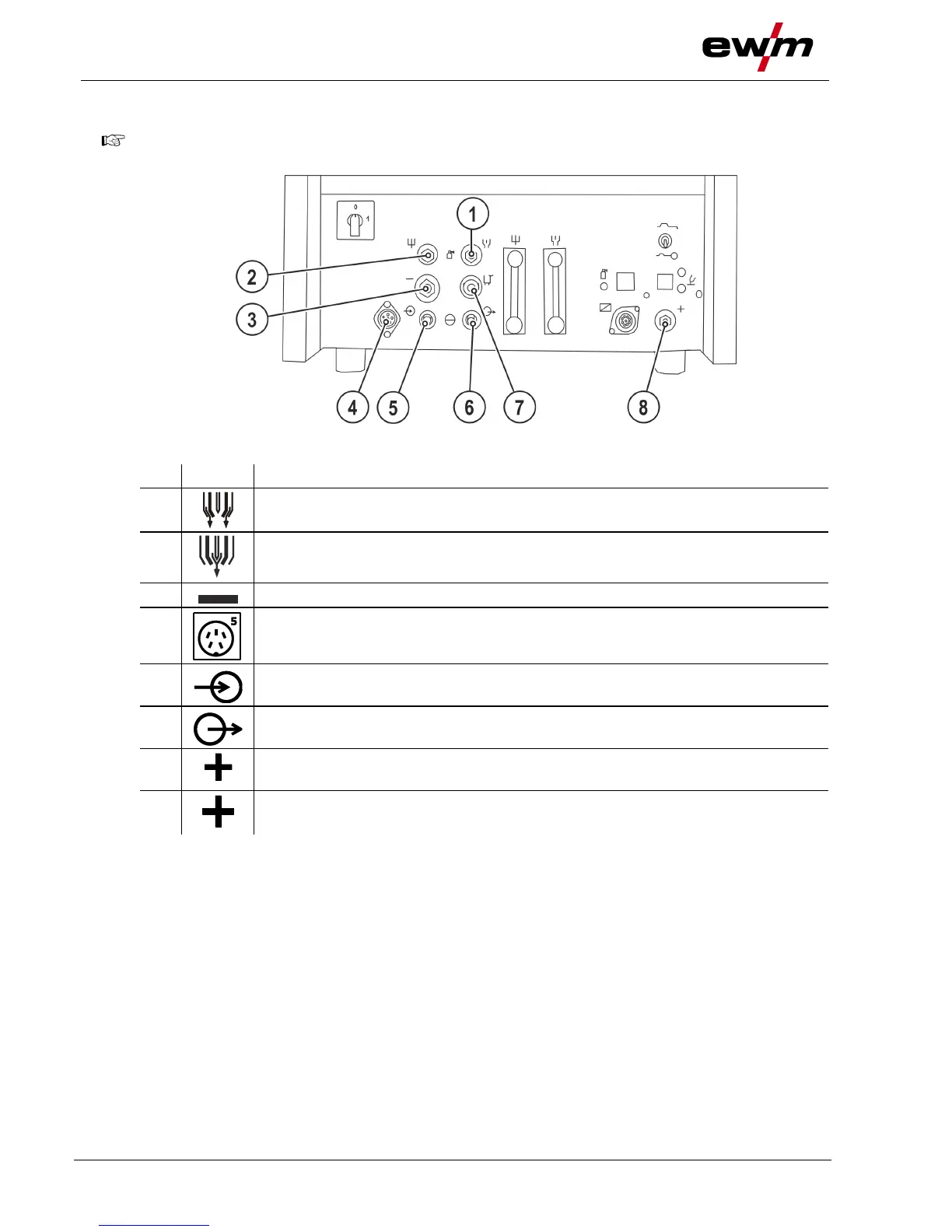

Shielding gas connection (coupling type 20)

Connection to the welding torch or gas metering unit

Plasma gas connection (plug nipple type 20)

Connection to the welding torch or gas metering unit

Welding current connection socket, welding torch

5-pole connection socket, welding torch control lead

Coolant return from welding torch

Coolant supply to the welding torch

Pilot current connection socket

Plasma welding torch nozzle potential

Connection socket, “+” welding current

Connection for workpiece lead

• Insert the plug on the welding current lead into the "-" welding current connection socket and lock.

• Insert the plug of the pilot power line into the "+" pilot current connection socket.

• Insert the torch control lead plug into the “5-pole connection socket, welding torch control lead” and

lock.

• Screw the connection coupling of the plasma gas line onto the G1/4" connecting nipple, plasma gas

connection.

• Screw the connection coupling of the shielding gas line onto the G1/4" connecting nipple, shielding

gas connection.

• Lock connecting nipples of the cooling water tubes into the corresponding quick connect couplings:

Return line red to quick connect coupling, red (coolant return) and

supply line blue to quick connect coupling, blue (coolant supply).

• Insert the cable plug on the work piece lead into the "+" welding current connection socket and lock by

turning to the right.

Loading...

Loading...