Design and function

Transport and installation

099-005221-EW501

05.09.2016

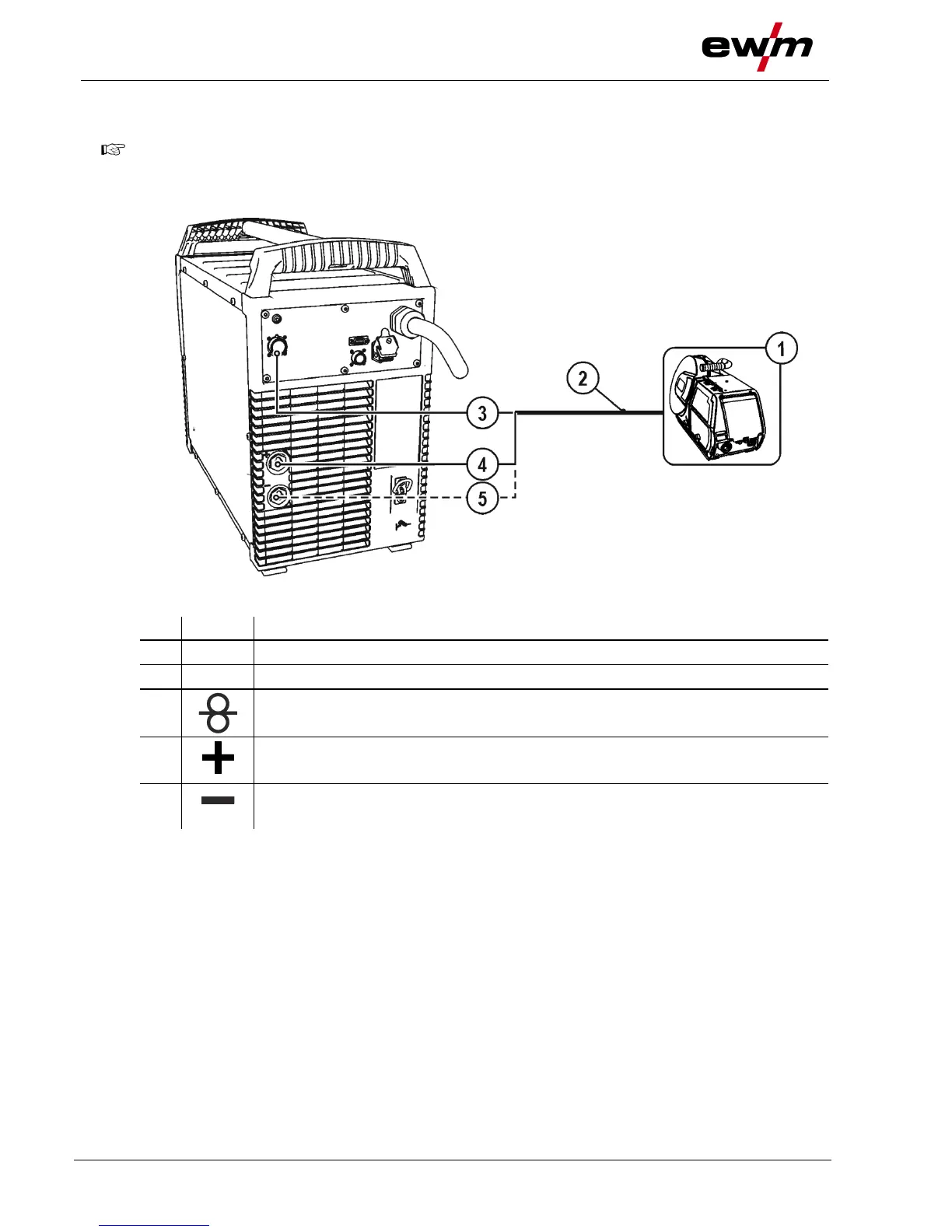

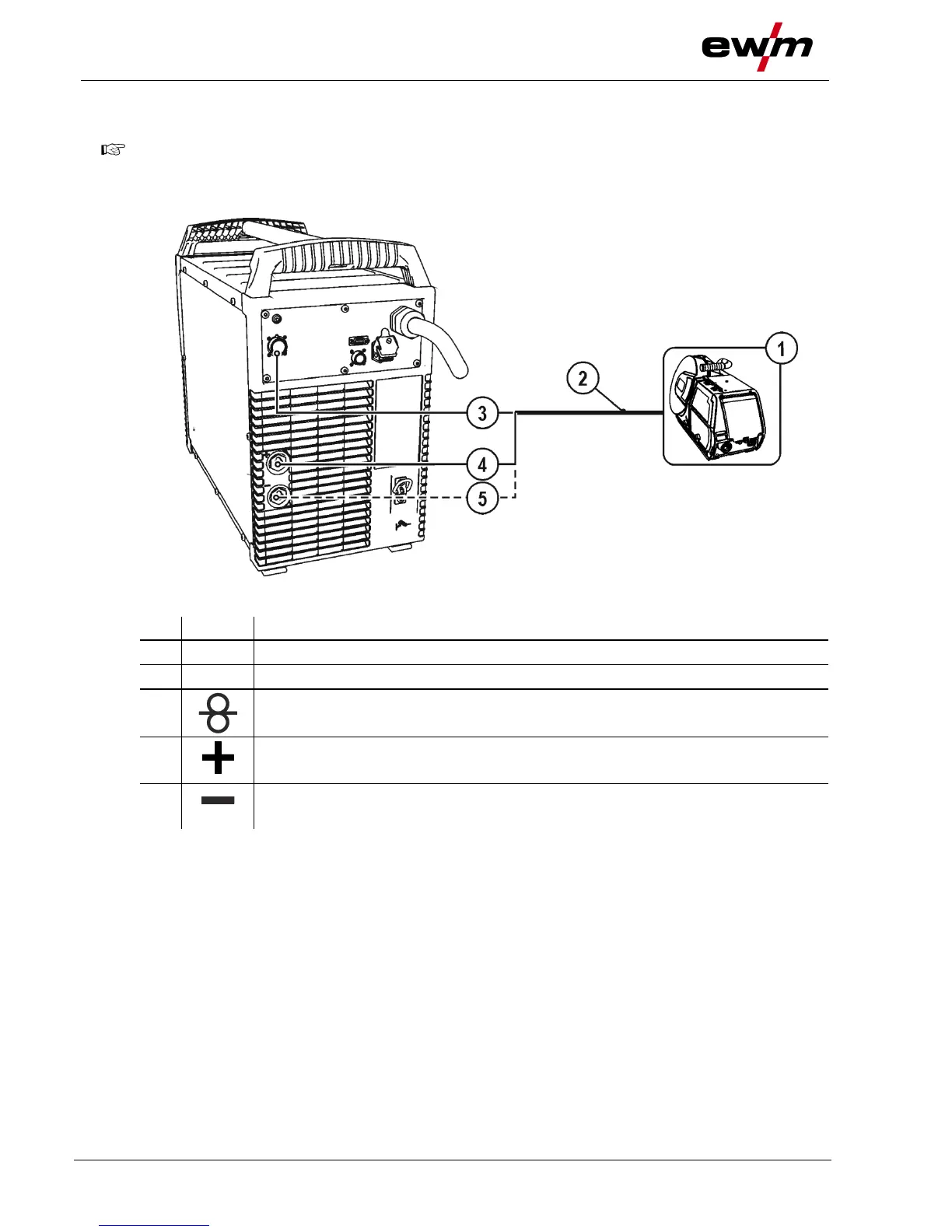

5.1.6 Intermediate hose package connection

Some wire electrodes (e.g. self-shielding cored wire) are welded using negative polarity. In this

case, the welding current lead should be connected to the "-" welding current socket, and the

workpiece lead should be connected to the "+" welding current socket. Observe the information

from the electrode manufacturer!

Intermediate hose package

19-pole connection socket (analogue)

Wire feed unit control lead connection

Connection socket, “+” welding current

• Standard MIG/MAG welding (intermediate hose package)

Connection socket, “-” welding current

• MIG/MAG cored wire welding:

Welding current to wire feed/torch

• Insert the welding current cable plug into the relevant welding current connection socket and lock by

turning to the right:

MIG/MAG cored wire: Welding current "-" connection socket

MIG/MAG standard: Welding current "+" connection socket

• Insert cable plug on the control lead into the 19-pole connection socket and secure with crown nut (the

plug can only be inserted into the connection socket in one position).

Loading...

Loading...