Design and function

Transport and installation

099-005221-EW501

05.09.2016

5.1.8 Notes on the installation of welding current leads

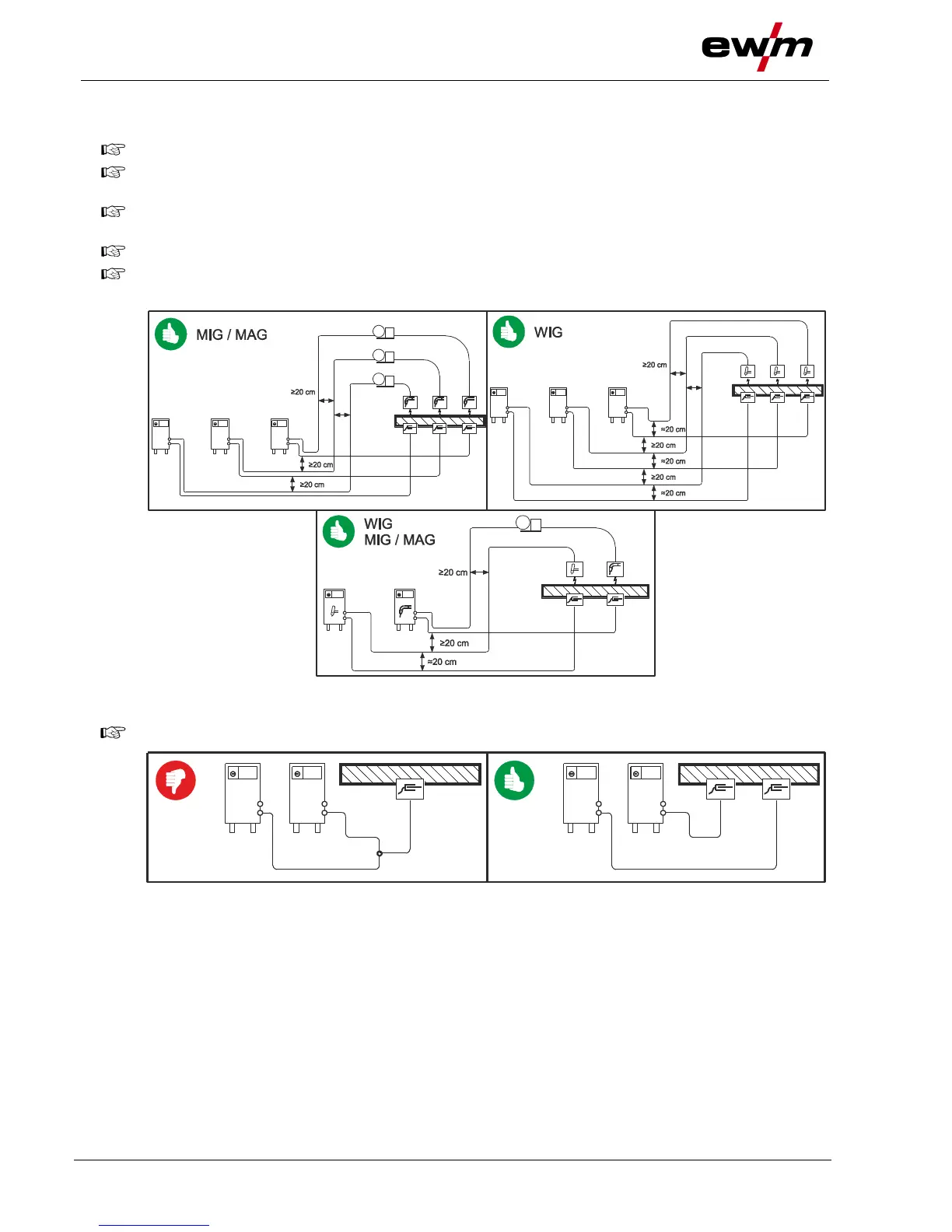

Incorrectly installed welding current leads can cause faults in the arc (flickering).

Lay the workpiece lead and hose package of power sources without HF igniter (MIG/MAG) for as

long and as close as possible in parallel.

Lay the workpiece lead and hose package of power sources with HF igniter (TIG) for as long as

possible in parallel with a distance of 20 cm to avoid HF sparkover.

Always keep a distance of at least 20 cm to leads of other power sources to avoid interferences

Always keep leads as short as possible! For optimum welding results max. 30 m (welding lead +

intermediate hose package + torch lead).

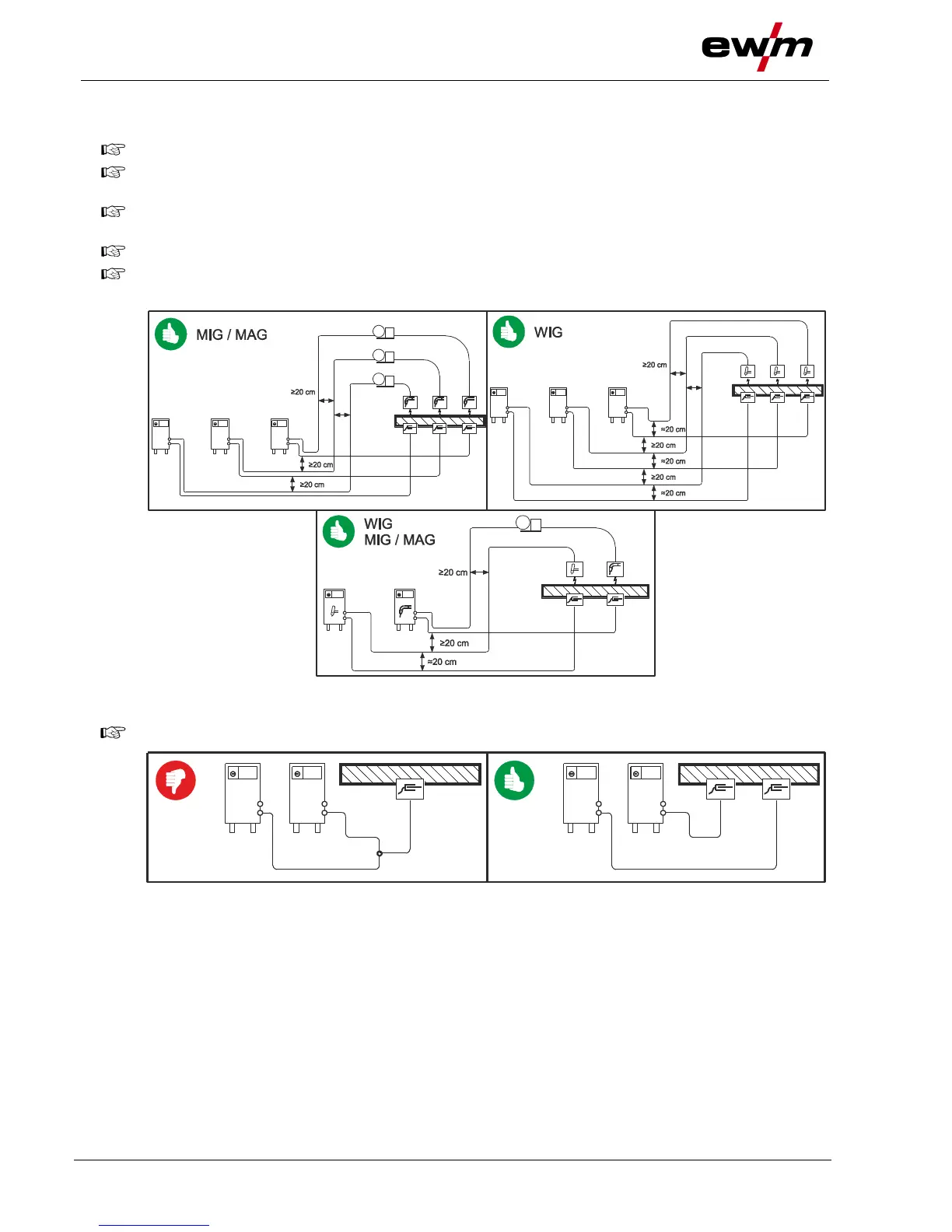

Use an individual welding lead to the workpiece for each welding machine!

Loading...

Loading...