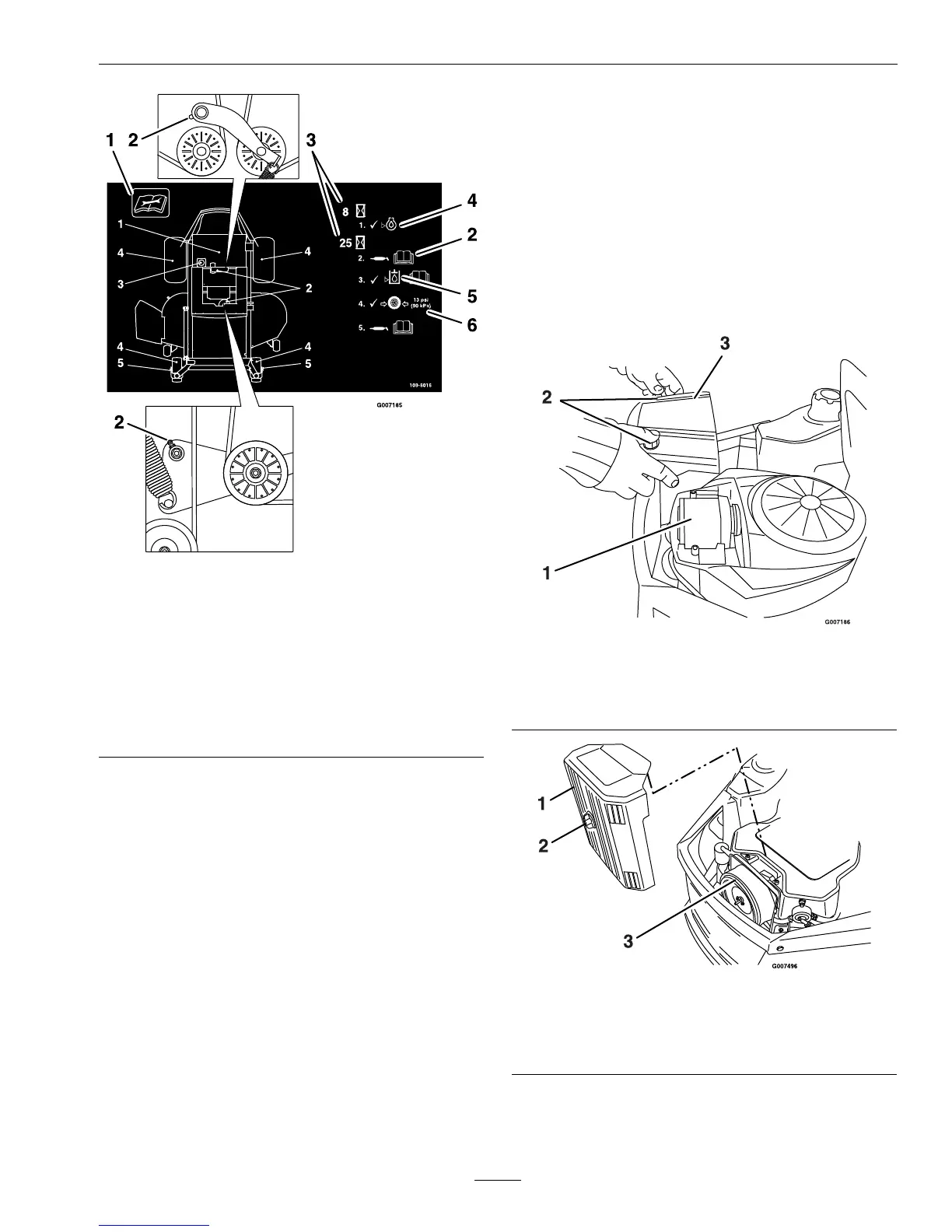

Maintenance

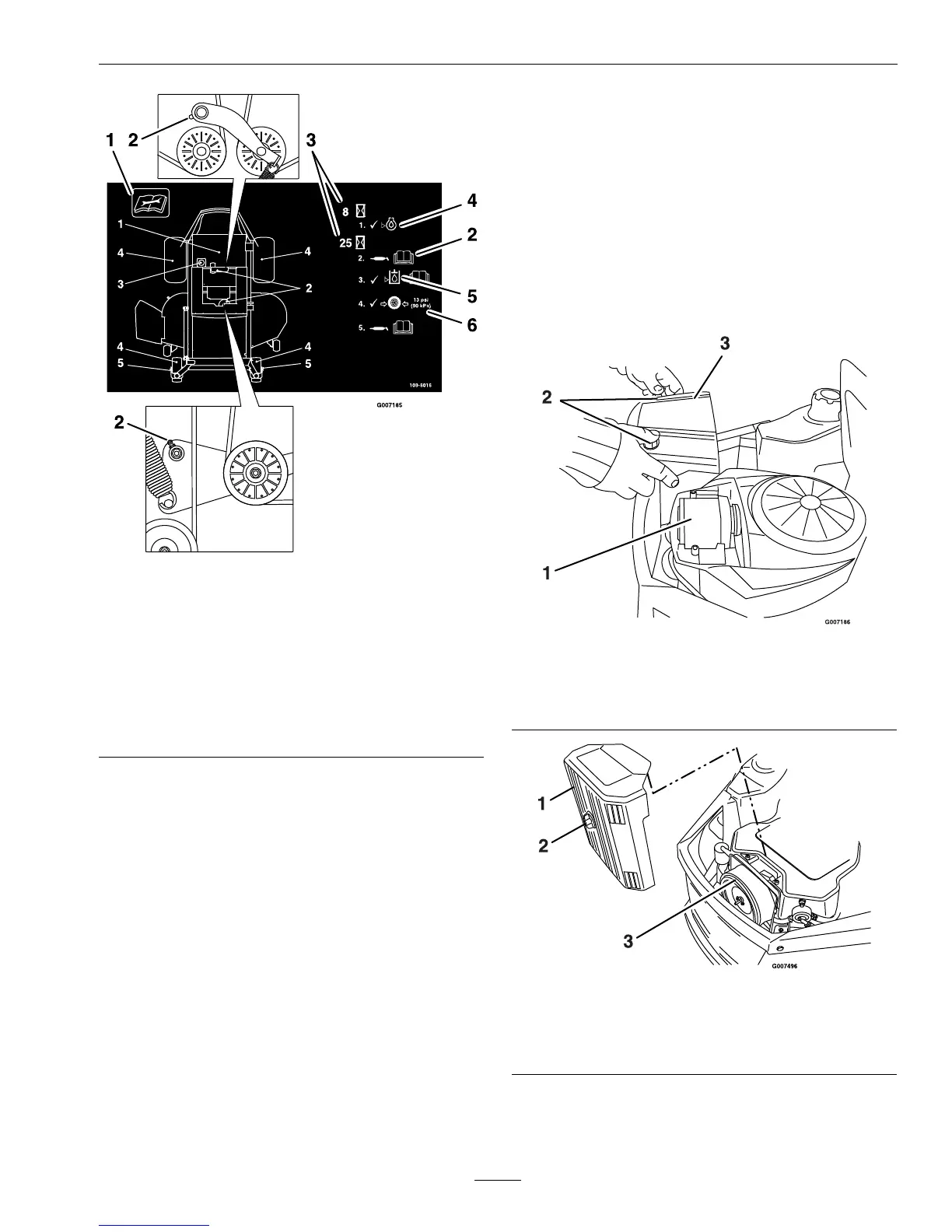

Figure22

Locatedonthebackoftheseat.

1.Readtheinstructions

beforeservicingor

performingmaintenance

4.Checkoillevel.

2.Greaseidlerpivots.5.Checkhydraulicoillevel

andrefertoOperator’s

manualforfurther

instructions.

3.Timeinterval.

6.Checktirepressure.

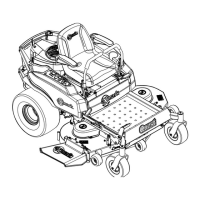

4.Connectagreaseguntoeachtting(Figure21

andFigure22).Pumpgreaseintothettingsuntil

greasebeginstooozeoutofthebearings.

5.Wipeupanyexcessgrease.

EngineMaintenance

ServicingtheAirCleaner

ServiceInterval:Beforeeachuseordaily

Every100hours—Replace

thepaperelement.(More

oftenunderextremely

dusty,dirtyconditions.)

Thisengineisequippedwithareplaceable,high

densitypaperaircleanerelement.Checktheair

cleanerdailyorbeforestartingtheengine.Checkfor

abuildupofdirtanddebrisaroundtheaircleaner

system.Keepthisareaclean.Alsocheckforlooseor

damagedcomponents.Replaceallbentordamaged

aircleanercomponents.

Note:Operatingtheenginewithlooseordamaged

aircleanercomponentscouldallowunlteredairinto

theenginecausingprematurewearandfailure.

Note:Servicetheaircleanermoreoftenunder

extremelydusty,dirtyconditions.

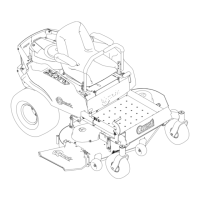

Figure23

Briggs&Strattonengine

1.Aircleaner3.Aircleanercover

2.Knobs

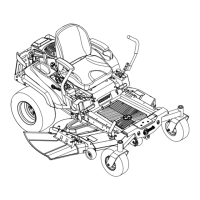

Figure24

KohlerCommandengine

1.Aircleanercover3.Aircleaner

2.Knob

31

Loading...

Loading...