Maintenance

3.Stoptheengine,removethekey,andwaitforall

movingpartstostopbeforeleavingtheoperating

position.

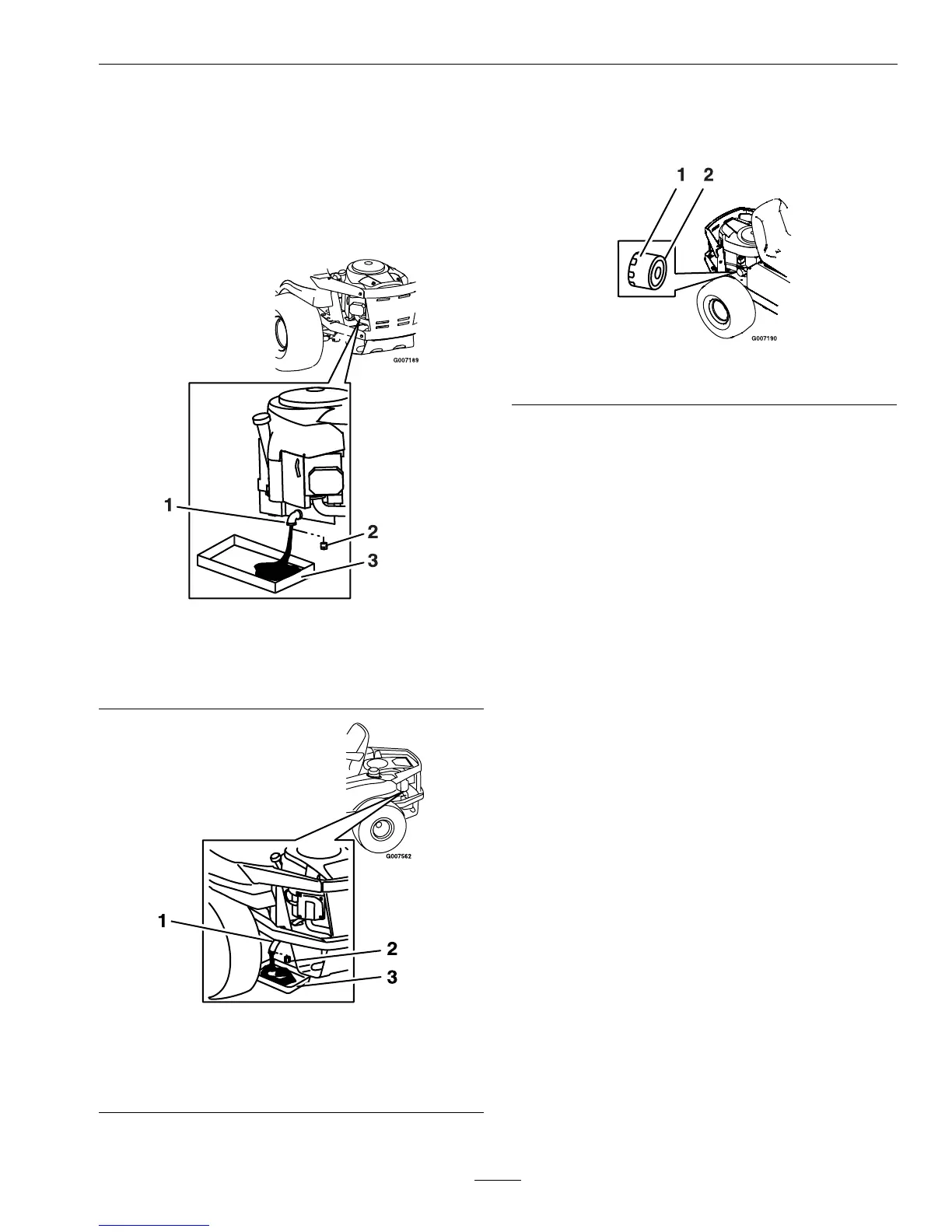

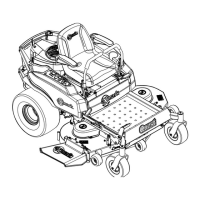

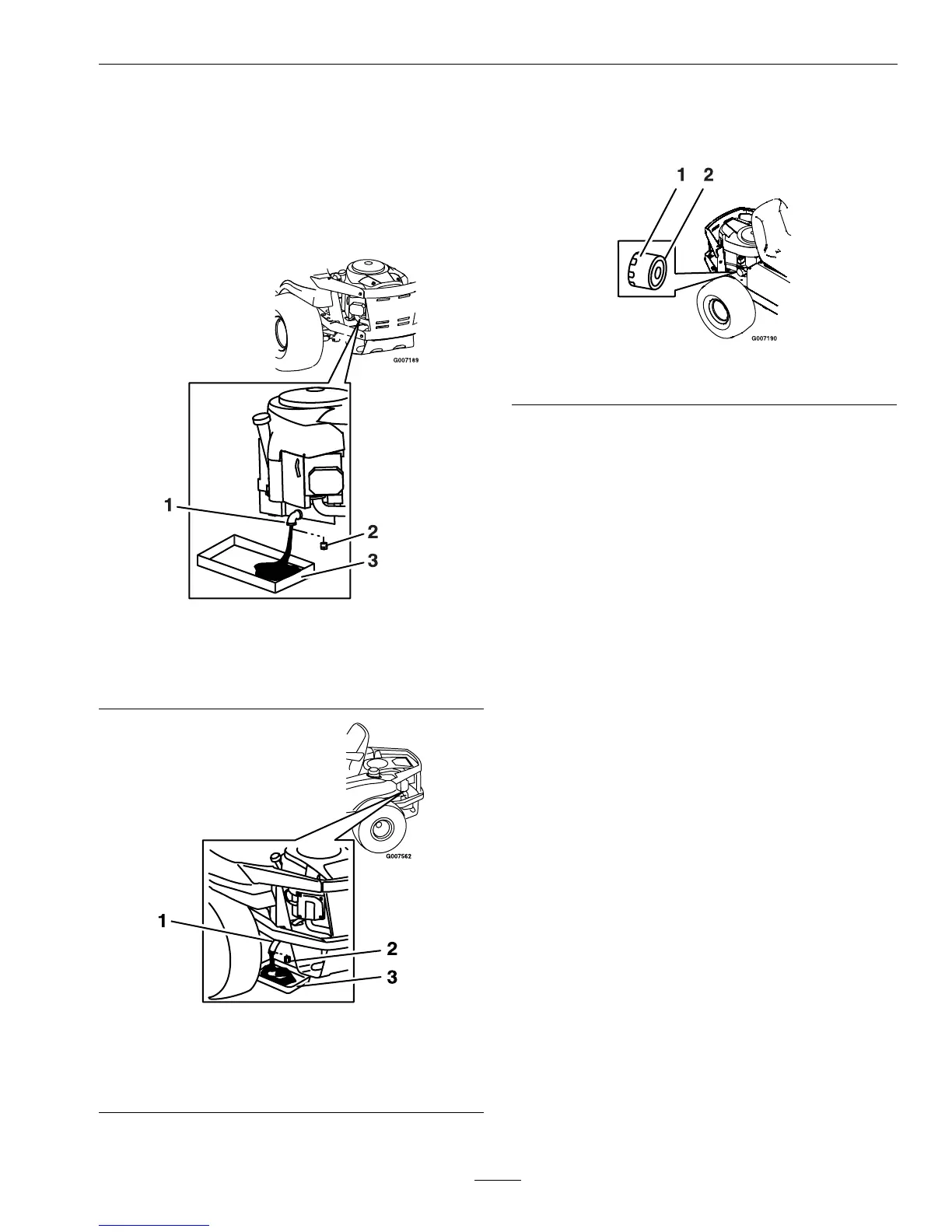

4.Cleantheareaaroundthedrainplugandonthe

machineframe.Placeapanunderneathmachine

directlybelowthedrainholeintheframeas

showninFigure26andFigure27.

Figure26

Briggs&Strattonengine

1.Oildrain

3.Pan

2.Oildrainplug

Figure27

KohlerCommandengine

1.Oildrainhose

3.Pan

2.Oildrainplug

5.Removetheoildrainplug(Figure26and

Figure27).Removetheoilllcap/dipstick

(Figure25).

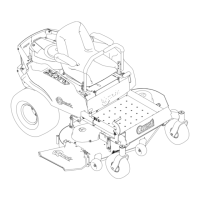

Figure28

1.Oillter2.Gasket

6.Besuretoallowampletimeforcomplete

drainage.

7.Removetheoldlterandwipeoffthemounting

pad(Figure28).

8.Whentheoilhasdrainedcompletely,installthe

oildrainplug.Tightentheplugto14N-m(125

in-lb)torque.Wipeupanyexcessoilontheframe

(Figure26andFigure27).

Note:Disposeoftheusedoilatarecycling

center.

9.Applyathinlmofcleanoiltotherubbergasket

onthenewlter.

10.Installthereplacementoilltertothemounting

pad.Turntheoillterclockwiseuntiltherubber

gasketcontactsthepad,thentightenthelteran

additional1/2to3/4turn(Figure28).

11.Slowlypourapproximately80%ofthespecied

oilintothellertube—useoilrecommendedin

theEngineOwner’sManual.

12.Installtheoilllcap/dipstickandpushrmly

intoplace.

13.Checktheoillevel(Figure25);refertoChecking

theOilLevel.

14.Slowlyaddadditionaloiltobringittothefull

mark.DoNotoverll.

15.Installtheoilllcap/dipstickandpushrmly

intoplace.

16.Starttheengineandcheckforleaks.

33

Loading...

Loading...