Maintenance

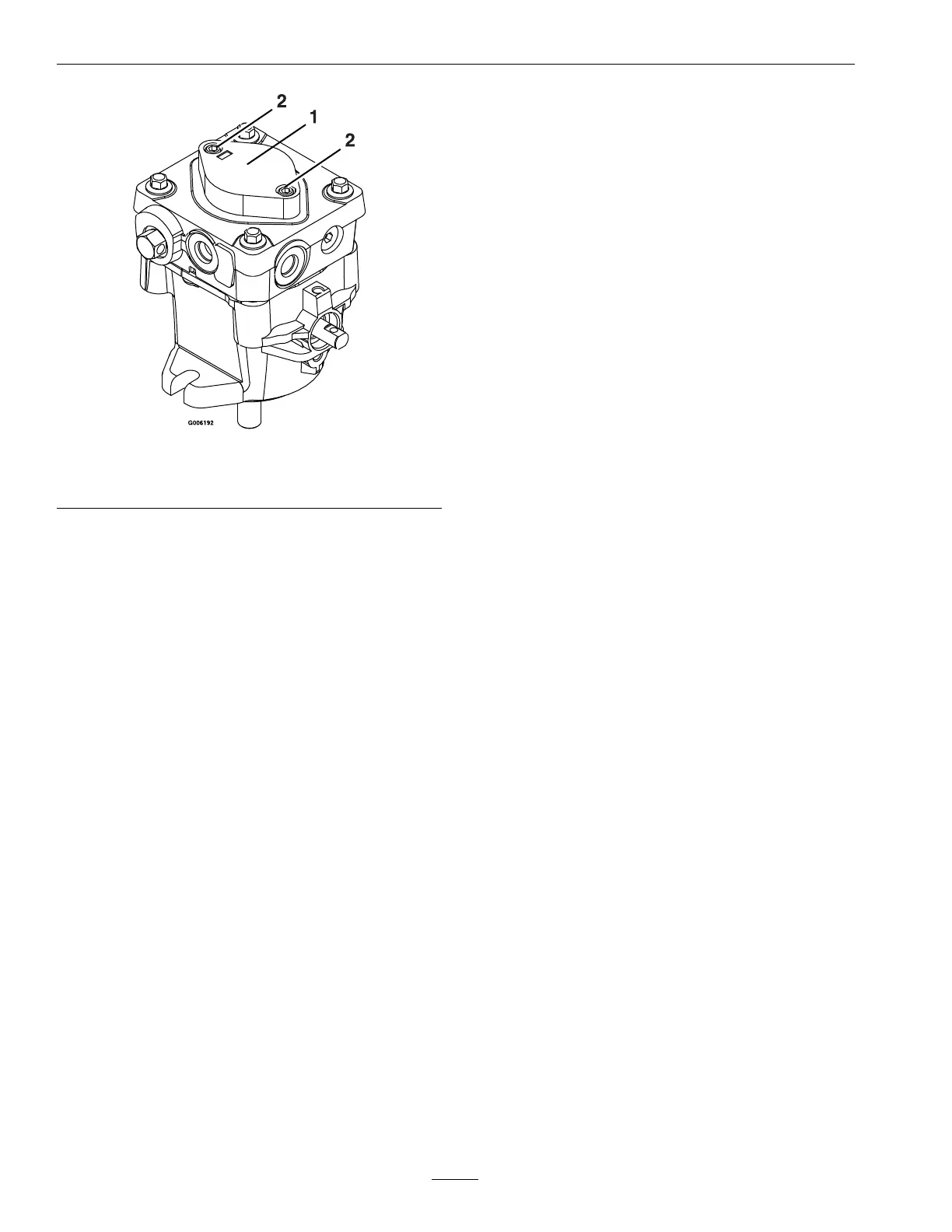

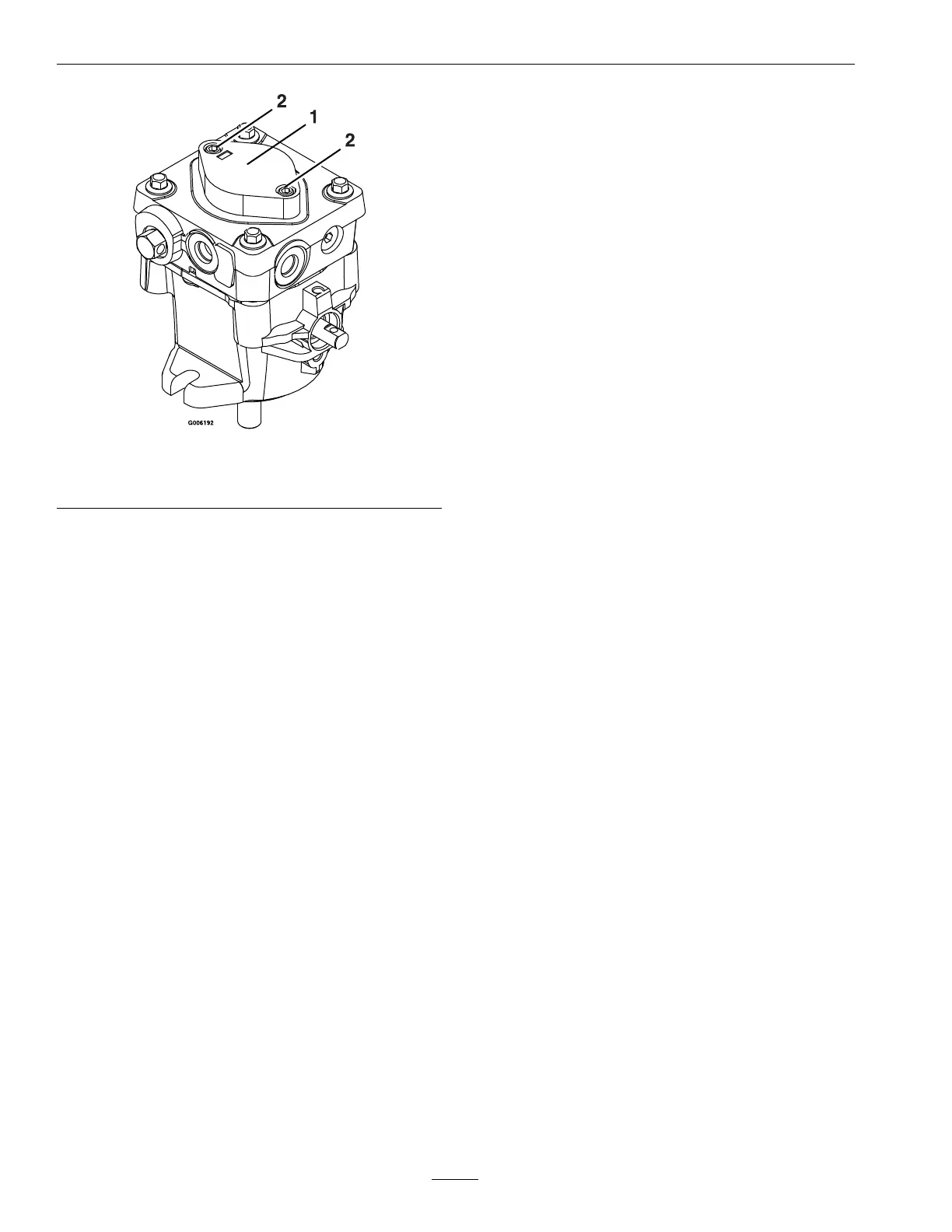

g006192

Figure8

1.Chargepumpcap2.Loosen11/2turnsonly

1.Stopengineandwaitforallmovingpartstostop.

Raisetherearofthemachineupontojackstands

highenoughtoraisethedrivewheelsoffthe

ground.

2.CheckoillevelasstatedinCheckHydraulicOil

Levelsection.

3.Startengineandmovethrottlecontrolaheadto

fullthrottleposition.Movethespeedcontrol

levertothemiddlespeedpositionandplacethe

driveleversinthe“drive”position.

Ifeitherdrivewheeldoesnotrotate,itispossible

toassistthepurgingofthechargepumpby

carefullyrotatingthetireintheforwardposition.

Note:Itisnecessarytolightlytouchthecharge

pumpcapwithyourhandtocheckthepump

temperature.Ifthecapistoohottotouch,turn

offengine.Thepumpsmaybedamagedifthe

pumpbecomestoohot.

Ifeitherdrivewheelstilldoesnotrotatecontinue

withstep4.

4.Thoroughlycleantheareaaroundeachofthe

chargepumphousings.

5.To“prime”chargepump,loosentwohexsocket

headcapscrews(showninFigure8)11/2turns

only.Makesureengineisnotrunning.Lift

thechargepumphousingupwardandwaitfor

asteadyowofoiltoowoutfromunderthe

housing.Retightenthecapscrews.Dothisfor

bothpumps.

Note:Hydraulicreservoircanbepressurizedup

to5psitospeedthisprocess.

6.Ifeitherdrivewheelstilldoesnotrotate,stop

andrepeatsteps4and5abovefortherespective

pump.Ifwheelsrotateslowly,thesystemmay

primeafteradditionalrunning.Checkoillevel

asstatedinChecktheHydraulicOilLevel

section.

7.Allowunittorunseveralminutesafterthecharge

pumpsare“primed”withdrivesysteminthefull

speedposition.CheckoillevelasstatedinCheck

theHydraulicOilLevelsection.

8.Checkhydrodrivelinkageadjustmentasstatedin

HydroDriveLinkageAdjustmentsectionin

Adjustments.

ReplaceEmissionsAirIntake

Filter

ServiceInterval:Every500hours

1.Stopengine,waitforallmovingpartstostop,and

removekeyorsparkplugwire(s).Engageparking

brake.

2.Removethelterfromtheventhose.

3.Insertanewlterintotheendoftheventhose.

ThreadLockingAdhesives

Threadlockingadhesivessuchas“Loctite242”

or“Fel-Pro,Pro-LockNutType”areusedonthe

followingfasteners:

•Pumpsheavesetscrews.

•Squareheadsetscrewsonhydropumpcontrol

arms.

•OPCleversetscrews.

•Shoulderboltsinendsofspeedcontrolcrank.

•Sheaveretainingboltinendofenginecrankshaft.

•Fueltankbulkheadttingthreads

Adhesivessuchas“LoctiteRC/609orRC/680”or

“Fel-ProPro-LockRetainingIorRetainingII”are

usedonthefollowing:

•OPCleverhubsandcross-shaft.

Note:Caremustbeusednottobondthe

bearing,nexttoeachOPChub,tothecross-shaft

30

Loading...

Loading...