Page 10 of 44

severely attenuates such interference. On the other hand, conducted RFI travels over conductive surfaces such as

power supply wires, electrical wiring of field devices, and worst of all; improper ground planes.

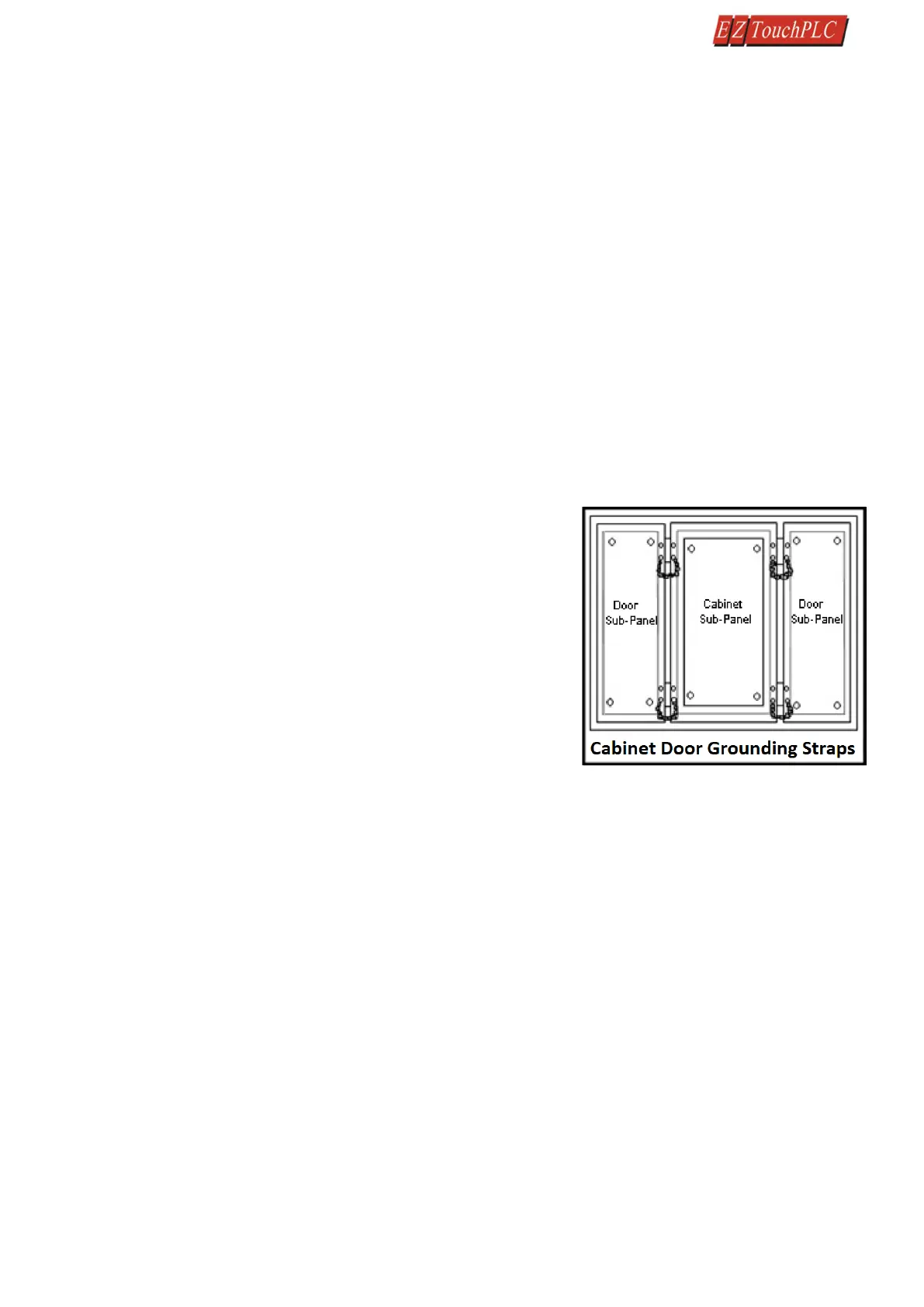

Equipment cabinets usually incorporate one or two doors and/or hinged cabinet panels. Relying on door hinges

and swinging panels for a good metallic bond between hinged parts and the main body of the cabinet does not

insure adequate grounding. Instead, the use of ground straps is recommended. It is vital for the reliable operation

of any electronic device to have any of its metallic surfaces well ground to Earth. This not only provides for safe

operation, it will also drain out any conducted RFI to Earth, away from the CPU's signal ground.

Shielding from RFI

Shielded Cables

Power cables, I/O cables or wiring, and communication cables should all be separate so that they do not couple

the conducted RFI on any of these wires/cables. Another path for RFI into the PLC is through its RS232 port. Hence,

the cables to this port must be shielded properly.

Equipment Cabinets

As mentioned, equipment cabinets typically incorporate one or two doors and/or hinged cabinet panels. In

addition, sub-panels may be utilized on those electronic controls and electromechanical items that are

mounted. The goal is to create a medium for mounting the equipment and ensure grounding of the control’s

chassis to it. However, the door hinges and swinging panels by themselves are not enough to ensure adequate

grounding.

Similarly, the equipment enclosures are generally either painted or

anodized. Mounting of painted or anodized enclosures to like surfaces

also does not ensure good metallic contact between the equipment

chassis and cabinet. It is imperative that the equipment chassis are

grounded such as through the use of grounding straps as illustrated

below.

Cabinet Wiring

The wiring of the EZ3 Series TOUCHPLC to the “field” outside the cabinet

must be by design. The wiring cannot be random in order to get the

various points of the cabinet and the “field” electrically connected.

Below are some general rules that apply in most situations: Provide a

separate power source to electronic controls and keep this power bus

away from any I/O power.

The cabinet should be wired with a safety ground (the main safety ground wire gauge is determined by the

cabinet’s total current consumption) and in accordance with all electrical code requirements. Once the cabinet

doors, stationary sub-panels and swing-out sub-panels have been “strapped” to the main cabinet, it is not

necessary to run safety ground wires from the equipment chassis terminals to the main safety ground connection.

The safety ground terminal of each component can, and should be, connected with the shortest wire possible, to

the cabinet or sub-panel frame. Plan the wiring routing. Keep all switched power in separate ducts and if there is

AC and DC power being switched, keep the wiring of each branch separate from all wires and cables carrying low

level signals.

Keep all three phase power outside of the cabinet, but if it becomes necessary, keep the runs as short as possible

and maintain the maximum possible distance between the three phase bus and all other wiring.

Primary power leads to the control equipment (Base power terminals) should be made with a two wire twisted

cable with approximately 12 turns per foot. The length of these cables should be kept to a minimum, and to the

greatest extent possible, such cable runs should be kept separate from other wiring.

Loading...

Loading...