Selection criteria

232

5.

SELECTING CRITERIA

Asynchronous spindle motor and servo drive selection

212

DDS

HARDWARE

Ref.1310

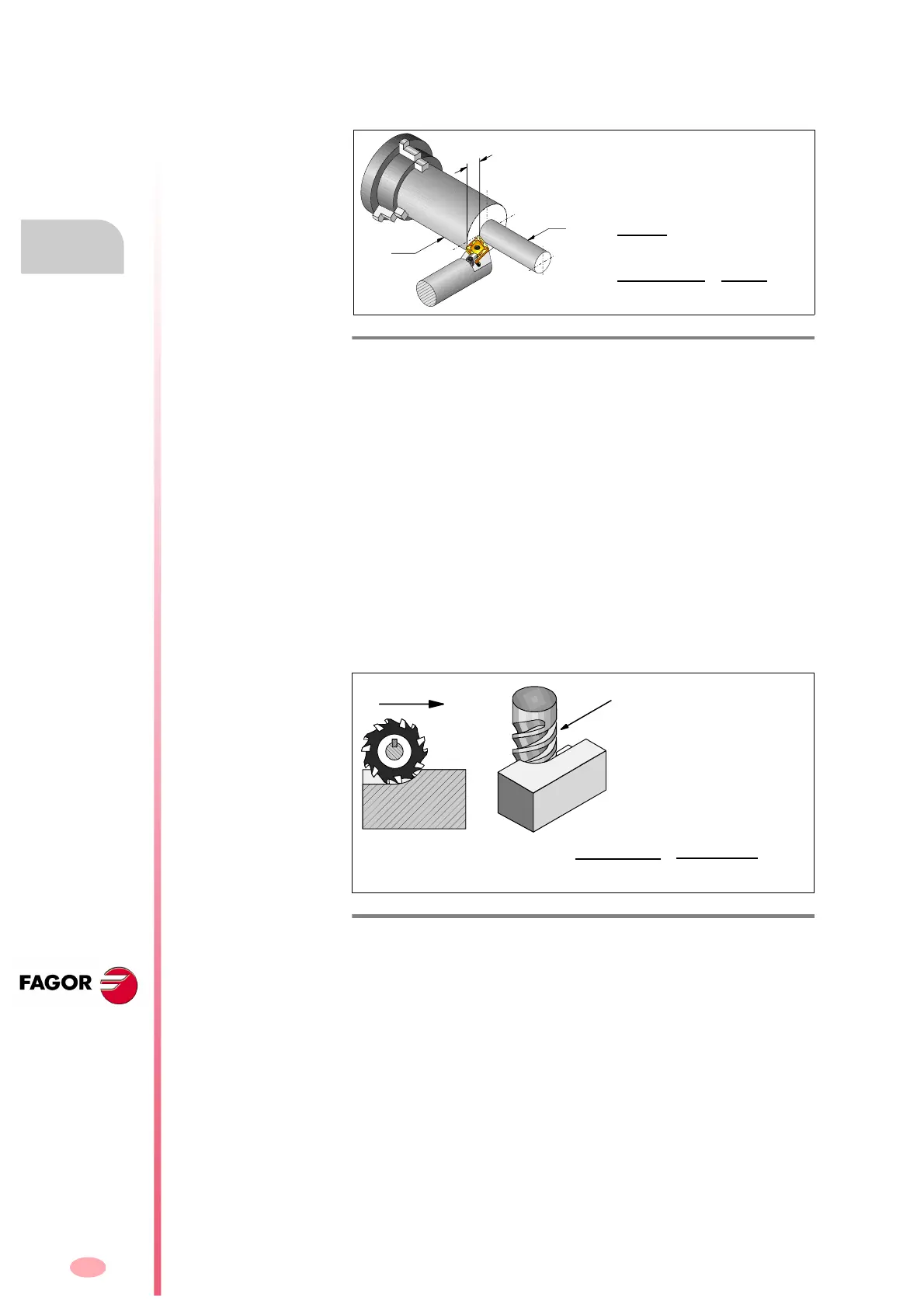

For lathe work, a cutting blade forces against the part to be machined,

while this is turning. See figure

F. H5/3.

The power required, Pc is calculated as follows:

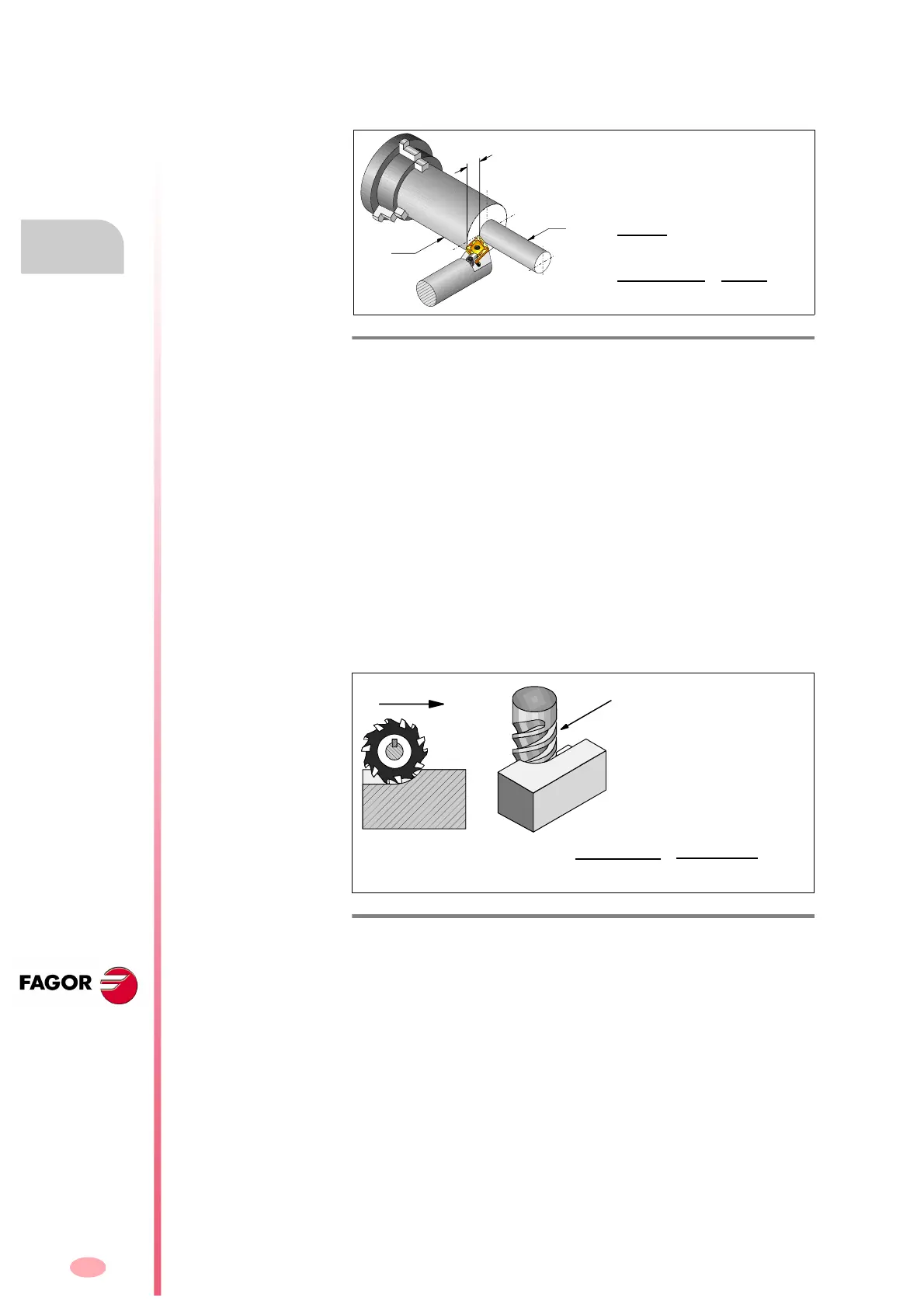

In the case of a milling machine, the cutter is mounted on the spindle it-

self and turns with this to cut the material. See figure

F. H 5/ 4 .

The power required, Pf is calculated as follows:

F. H5/3

Machining for lathe. Cutting power.

V

Cutting speed in m/min

K

s

Relative cutting resistance in N/mm²

d

Cutting depth in mm

L

Length of the blade, or feedrate per full turn in mm

D

Diameter of the part machined in mm

N

s

Spindle turning speed in rpm

c

Mechanical efficiency (varies from 0.7 to 0.85)

S

c

Cutting efficiency. Cutting volume per kilowatt every minute

in (cm³/kW)/min

F. H5/4

Machining for mill. Cutting power.

K

s

Relative cutting resistance in N/mm²

d

Cutting depth in mm

W

Cutting width in mm

f

Feedrate in mm/min

N

s

Spindle turning speed in rpm

f

Mechanical efficiency (varies from 0.7 to 0.8)

S

f

Cutting efficiency. Cutting volume per kilowatt every minute

(cm³/kW)/min

V =

·d·N

s

1000

(m/min)

P

c

=

K

s

·d·L·v

60·1000·

c

=

d·L·v

S

c

·

c

(kW)

P

f

=

K

s

·d·W·f

60·1000²·

f

=

d·W·f

1000²·S

f

·

f

(kW)

Loading...

Loading...