Selection criteria

SELECTING CRITERIA

Asynchronous spindle motor and servo drive selection

5.

213

DDS

HARDWARE

Ref.1310

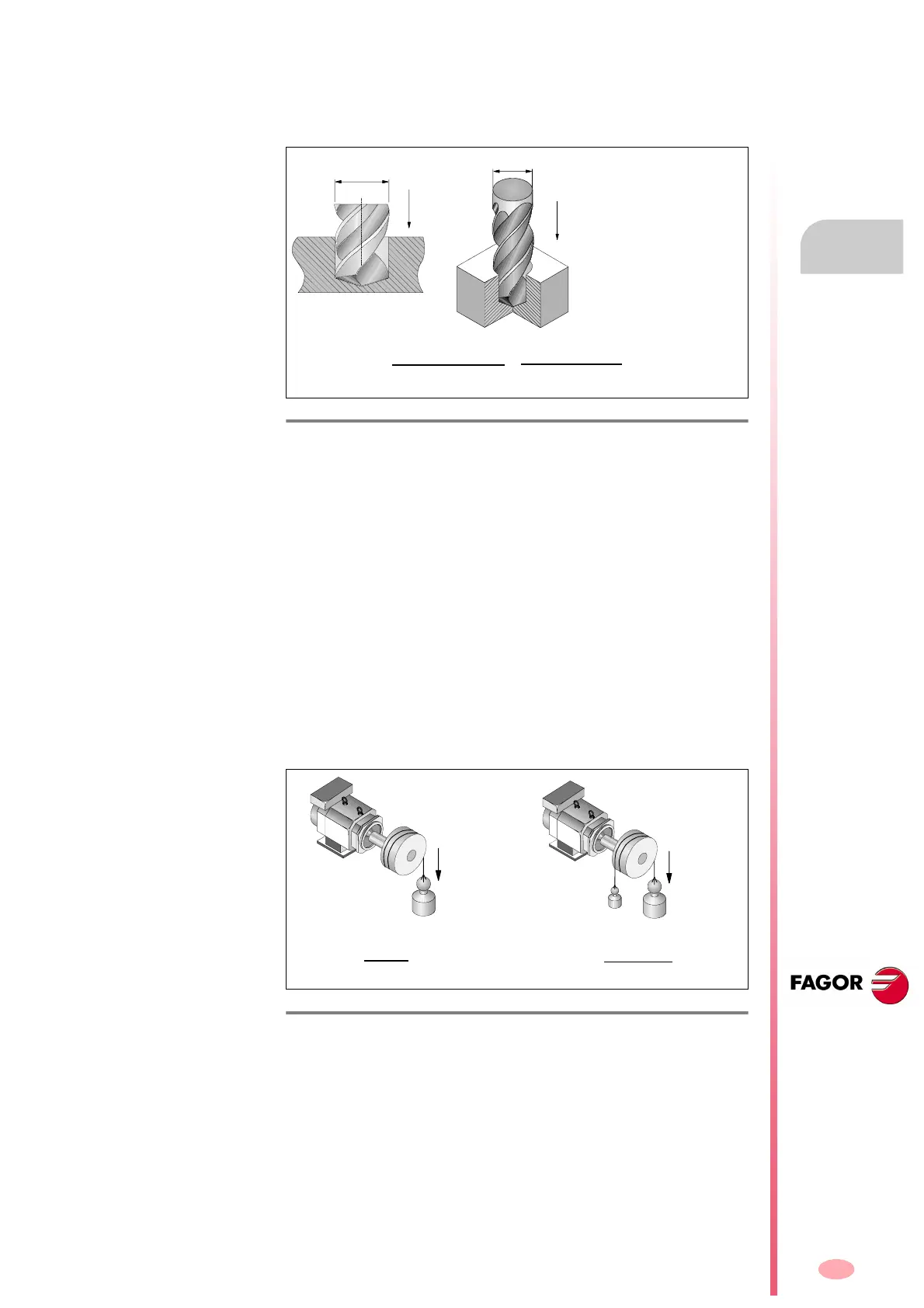

In the case of a drill, the bit is mounted on the spindle itself and turns with

this to drill the material. See figure

F. H5/5.

The power required in this case Pd may be calculated with the following

formula:

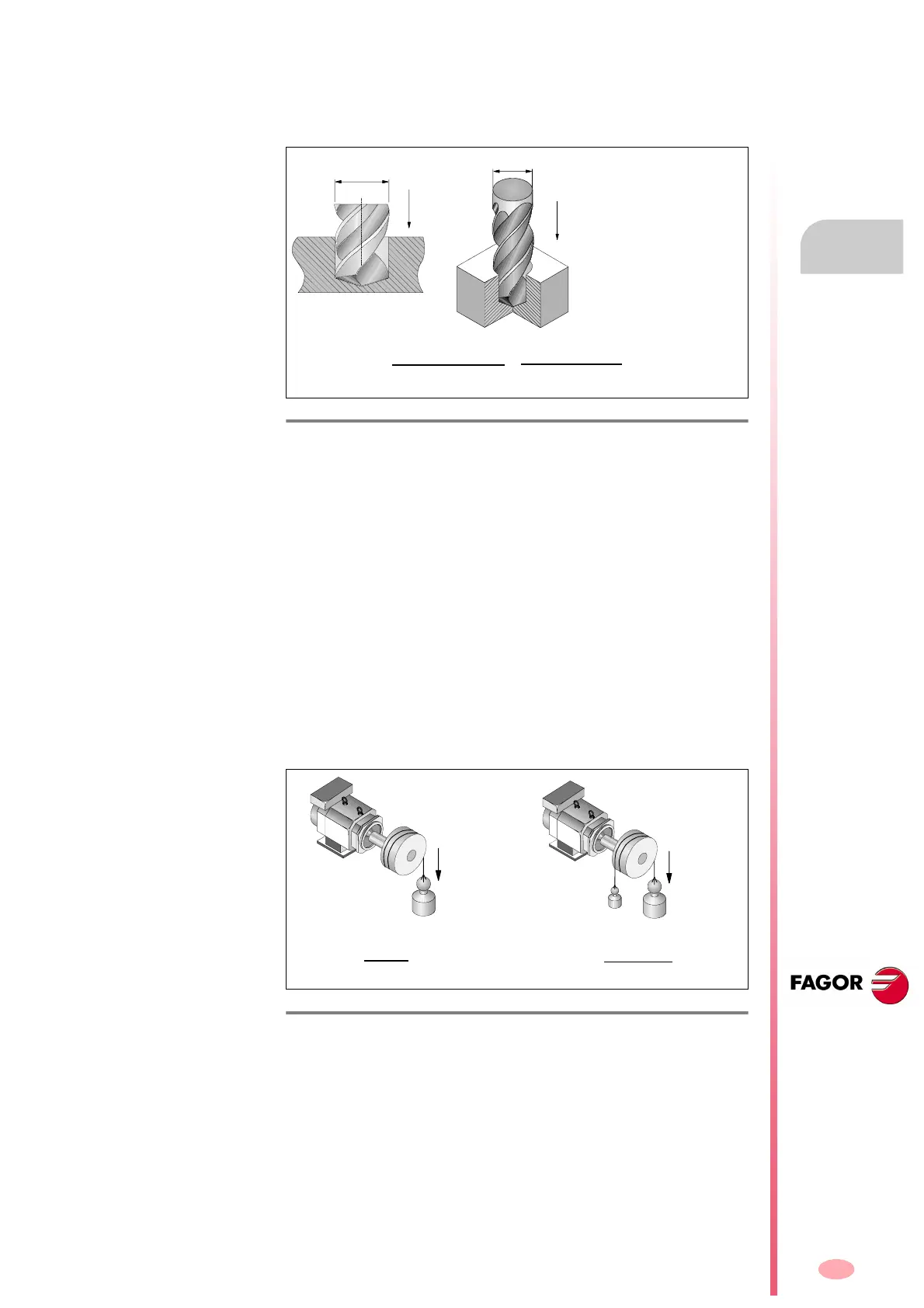

In the event of governing a

gravitational load, the power required de-

pends very much on the presence on absence of balance weights (crane

or elevator).

See figure F. H5/6.

The power required in this case, P

GL

and P

GLC

may be calculated as fol-

lows:

Governing a

frictional load, this is the case of horizontal movements

such as a conveyor belt or a movable table, the required power depends

on the friction coefficient µ

. See figure F. H 5/ 7 .

F. H5/5

Drilling. Required power.

M

Drilling load torque in N·cm

n

Spindle turning speed in rpm

D

Hole diameter in mm

f

Feedrate in mm/min

d

Mechanical efficiency (varies from 0.7 to 0.85)

S

d

Cutting efficiency. Cutting volume per kilowatt every minute

(cm³/kW)/min

F. H5/6

Gravitational load. Required power.

V

Linear speed in m / min

Mechanical efficiency

m

L

Table mass in kg

m

C

Counterweight mass in kg

P

d

M· 2

·n

60·100·1000·

d

=

·D²

·f

4·1000·S

d

·

d

(kW)

=

Drum

Load

Balance

weight

Motor

Speed

Loading...

Loading...