Installation

INSTALLATION

Connection of the control and communications signals

8.

303

DDS

HARDWARE

Ref.1310

Making all these connections will conclude the connection process. See fig-

ure.

F. H8/33

CAN cable to connect a CNC and two drives.

NOTE. Note that the connectors of the intermediate modules (when con-

necting several drives in the bus) receive two wires, in each pin of the

CAN connector, coming from each adjacent module. The connectors of

the modules at either end only receive one.

F. H8/34

General connection diagram for the CAN bus between the drives and the

master device (CNC, etc.). CAN cable connection.

NOTE. No more than six drive modules (axes + spindles) can be connect-

ed in the CAN bus.

ISO GND

CAN L

SHIELD

CAN H

SHIELD

1

2

3

4

5

5

4

3

2

1

Pin Pin

SHIELD

CAN H

SHIELD

CAN L

ISO GND

5

4

3

2

1

Pin Pin

5

4

3

2

1

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

ADDRESS=1

LINE TERM=0

01

SHIELD

CAN H

SHIELD

CAN L

ISO GND

DRIVE MODULE 1

C

D

E

F

0

B

A

9

8

1

7

2

6

3

5

4

ADDRESS=2

LINE TERM=1

01

SHIELD

CAN H

SHIELD

CAN L

ISO GND

DRIVE MODULE 2

ISO GND

CAN L

SHIELD

CAN H

SHIELD

CNC

11

1

Pay attention to

this wire crossing

when connecting

the cables.

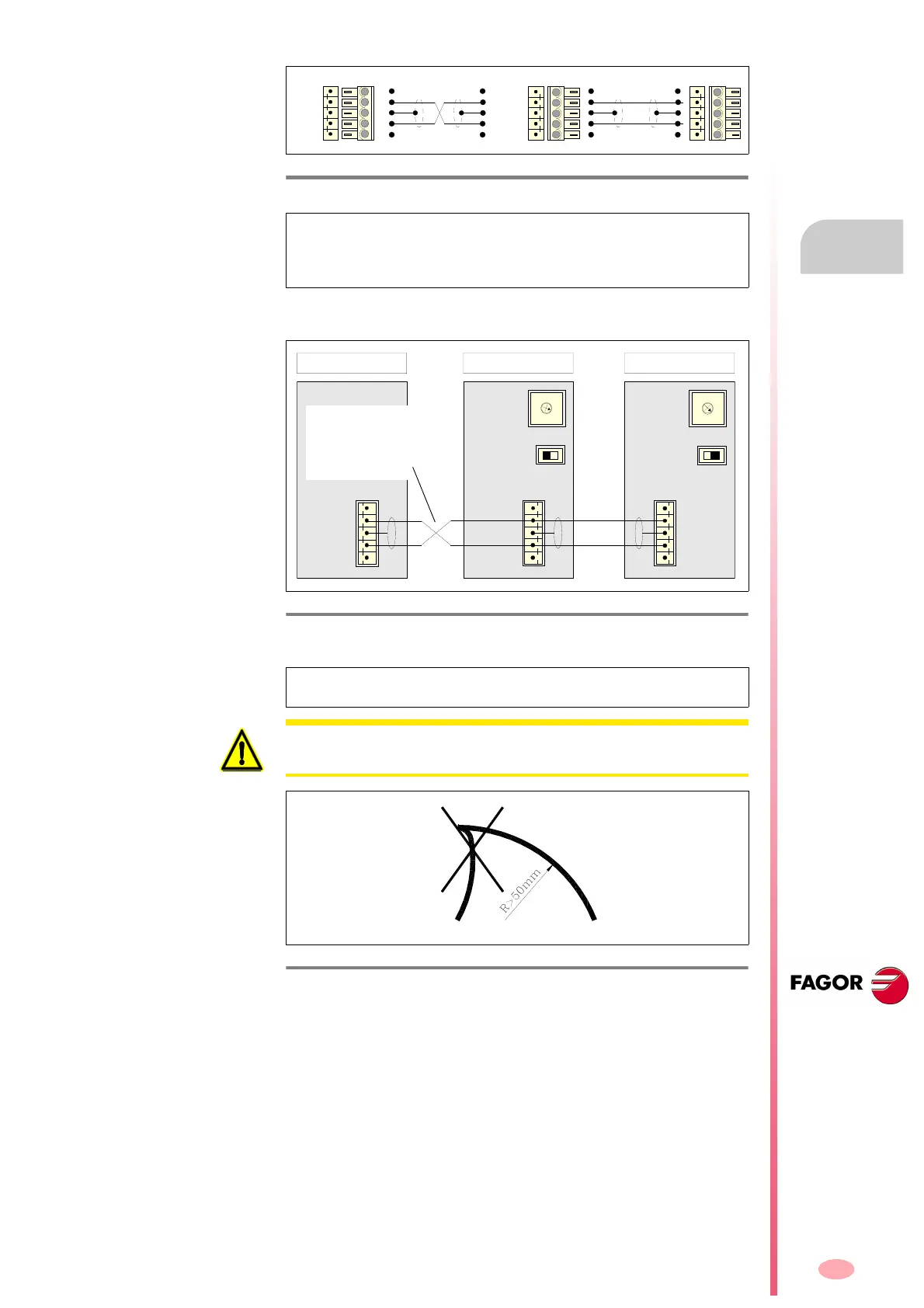

WARNING. The bending radius of the CAN cable must always be more

than 50 mm.

F. H8/35

Minimum bending radius of the CAN cable.

Loading...

Loading...