www.fastech.co.kr

12. Other Operation Functions

*1 : The unit of [pps] in this item is referenced to 10,000[ppr] encoder.

Input signal(PT Start) Method

Firstly the position table data must be entered before the push motioning and

refer to 「User Manual – Position Table Function」.

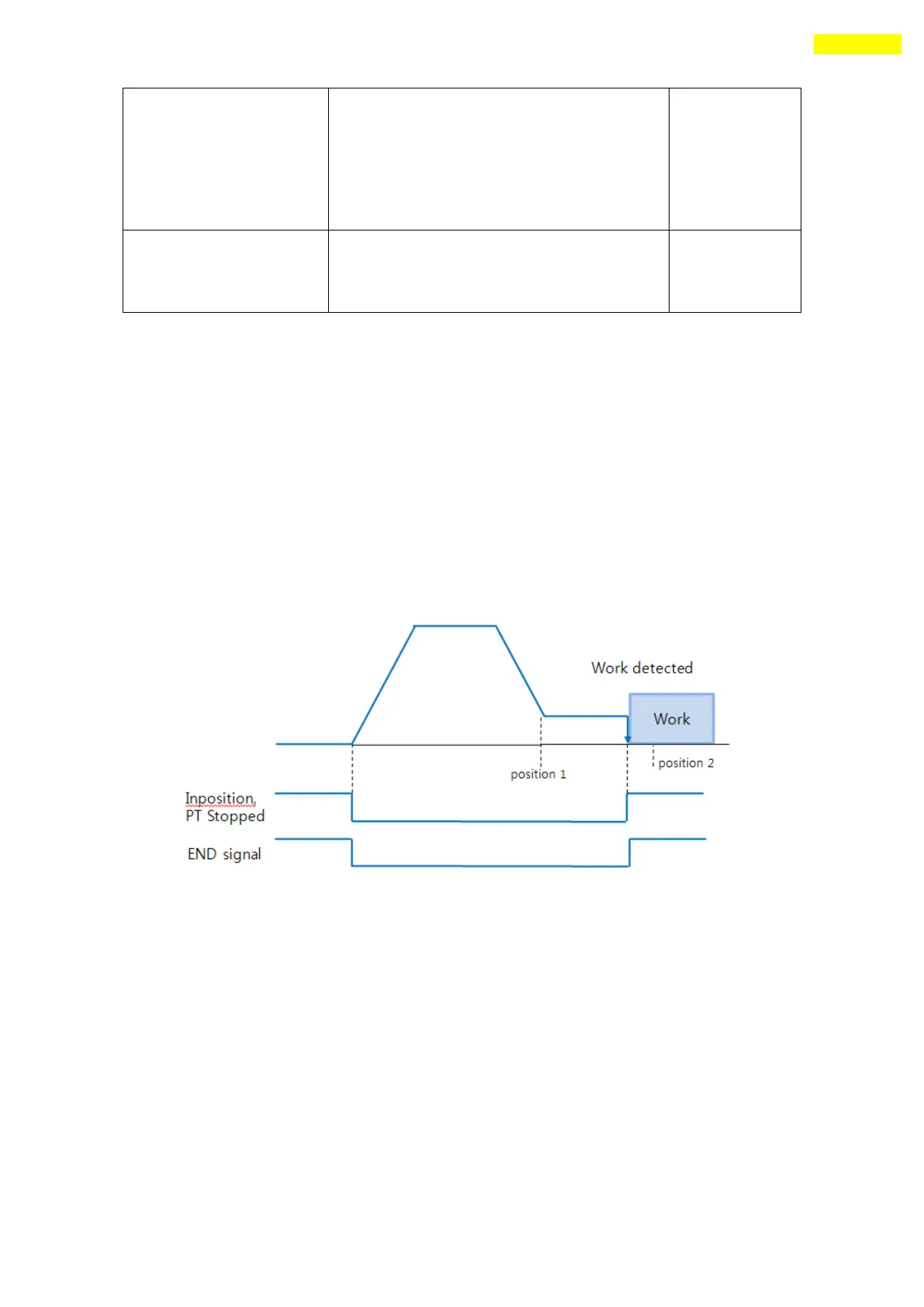

(4) Status Check

Basically the current push motion status can be checked by DLL library and

Additionally can be checked by Flag(Inposition & PT Stoped signal) and Output

(END signal) as follows.

Work detected

Work not detected

The ‘Inposition’ and other signals are still OFF when the work is not detected.

By ‘stop’ command these signals change to ON status. If the work is overdue

after work detect(‘Inposition’ signal is ON), the ‘Inposition’ signal change to OFF

status. But the ‘PT Stopped/END’signal is still ON after the first work detect.

The push command is stoped at ‘position 2’(absolute position value in push command).

(5) Alarm

Basically the alarm (#3 and #4) function is not working during push motion moving.

This is because of the position error and overload alarm can be happen in push mode.

If the alarm happens during return to start position after finishing push motioning,

increase the parameter ’27. Position Tracking Limit’value.

(‘position 2’ of Figure10.6.1)

*Non-stop mode : the value must be set

more than ‘ Position command Target

Position’ value.

*The motor will stop if the position is

exceed this value even if the work is not

detected.

Set Stop mode(0) or Non-stop mode(1~

10000) after the work detect. In case of

Non-stop mode, the motor move backward as

much as this value[pulse] distances.

Loading...

Loading...