F 40 9

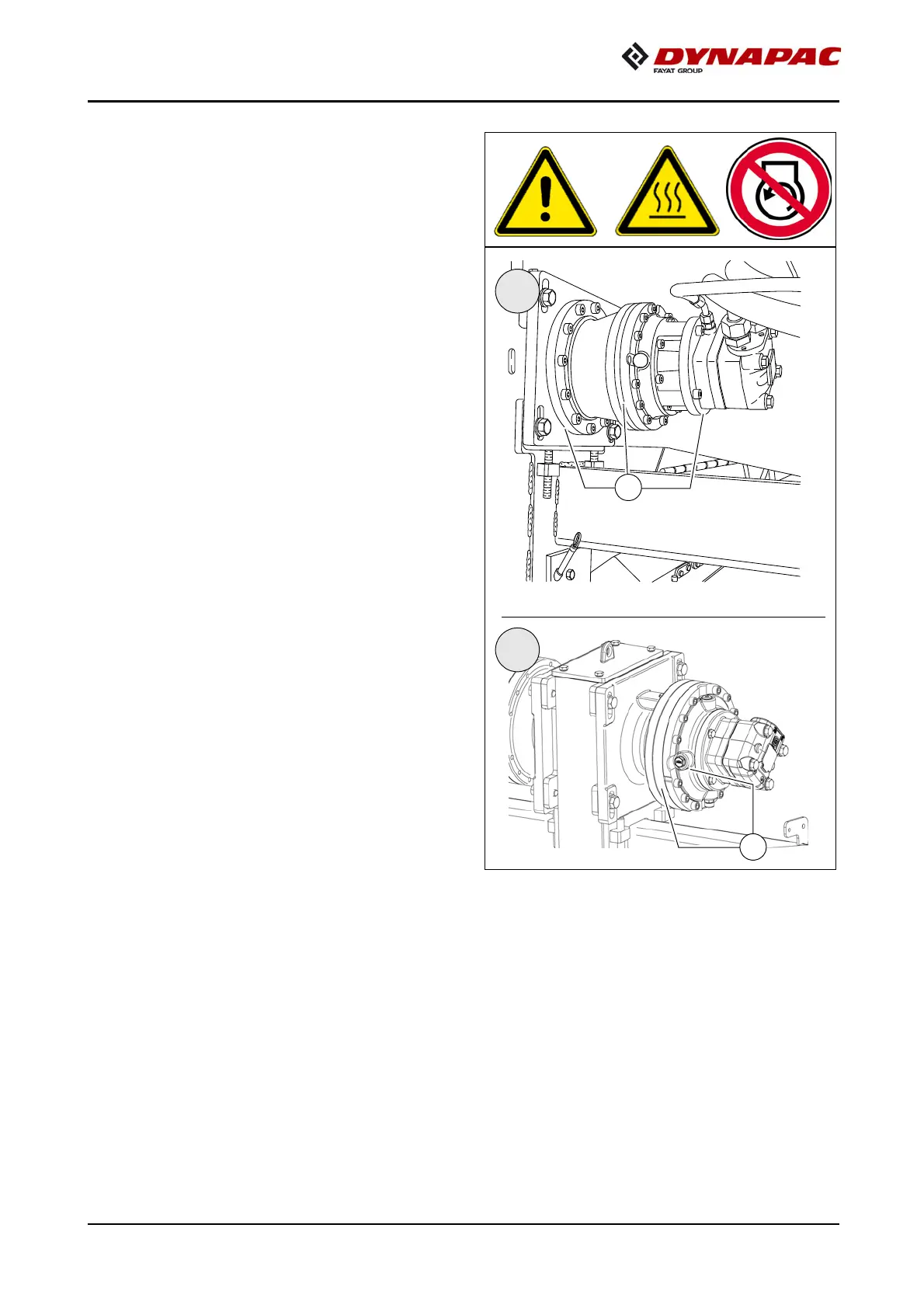

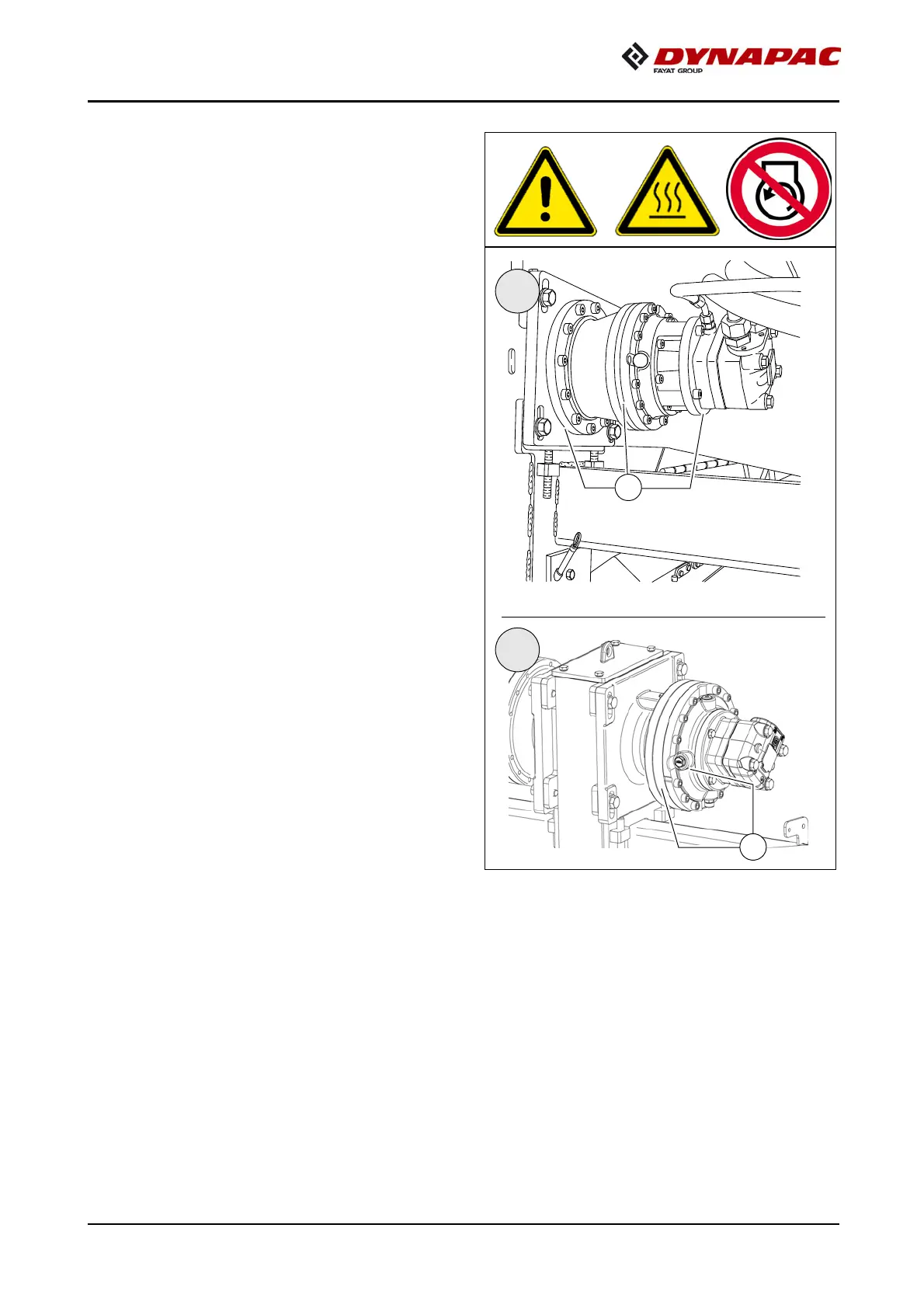

Seals and sealing rings (5)

A

After reaching operating temperature,

check the gearbox for leaks.

m

In case of visible leaks, e.g. between the

flange surfaces (A) of the gearbox, re-

placement of the seals and sealing rings

is necessary.

Loading...

Loading...