Page. 27

8

.䎃 Maintenance and Checking䎃

䦟䎃 8-2-3.

Zero-point compensation (Zero Adjust press Enter)

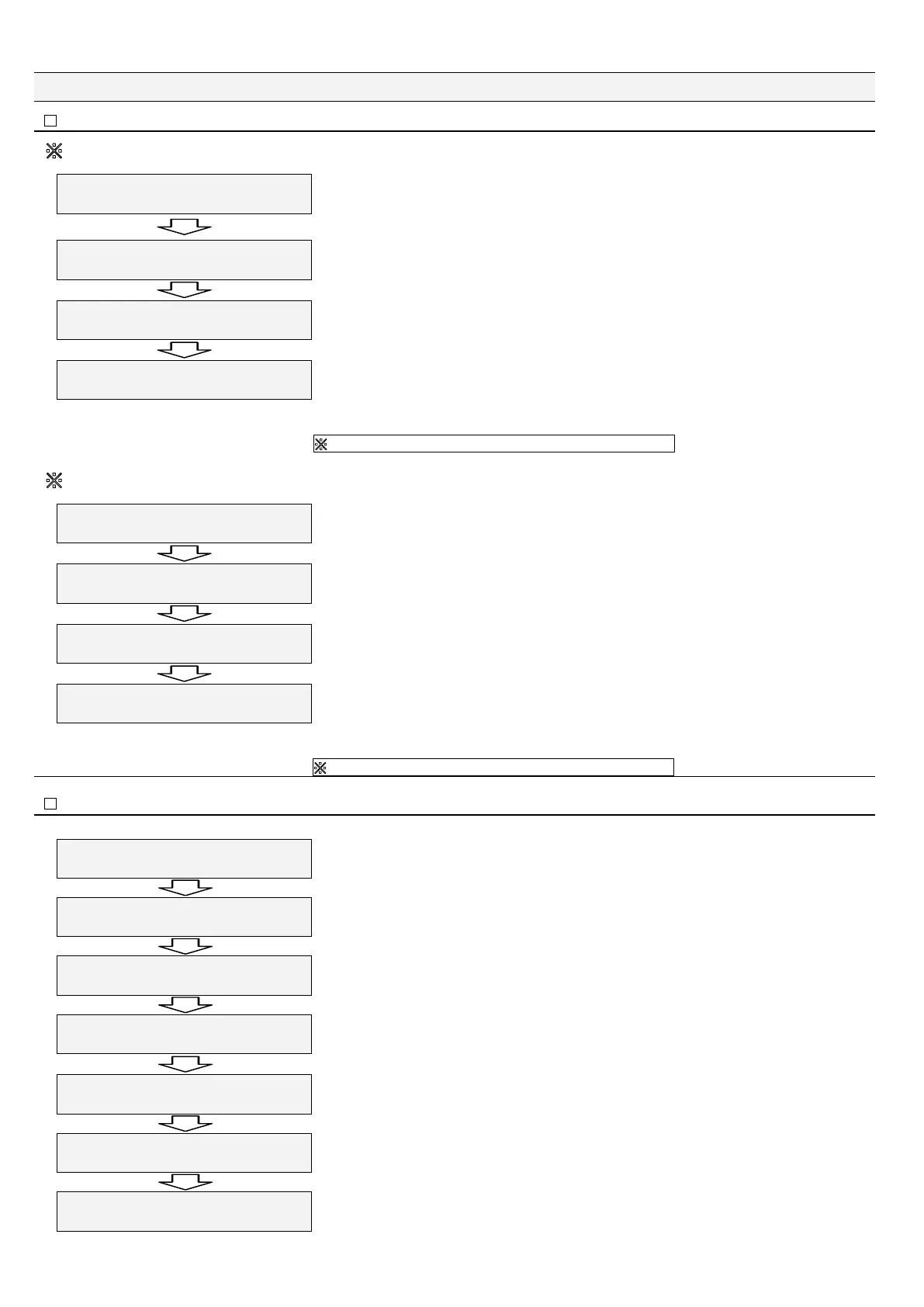

䚚A

The zero-point compensation is disabled when oil concentration over 5 ppm is detected in the zero-point compensation after sensor

cleaning because of oil or residue of contaminant in the detection tube.

<GTQEQORA

(CKN\GTQEQORGPUCVKQP

This example shows a case that an oil concentration over 5 ppm is detected.

Shows an oil concentration outside the compensation range.

This example shows compensation of oil concentration from 5 ppm to 0 ppm.

Press "Enter."

9CUJKPI'UESWKV

ZZZ

Opens the fresh water valve to flush fresh water into the detection tube to keep the performance of

the tube. The remaining flushing time is displayed on the lower right part of the screen.

/CKPVGPCPEG/QFG

2TGUUGPVGTVQEQPVKPWG

Press "Enter."

On the next screen, you can select one of two methods.

/CKPVGPCPEG/QFG

<GTQCFLWUV0)QPGOQTG

Press "Esc" to go back to "Main Menu" or press "Enter" to retry the zero-point compensation. (It

is recommended to turn off the oil concentration detector and clean the sensor before retrying the

zero-point compensation function.)

With this, the explanation is completed about the failure of the zero-point compensation when an oil concentration over

5 ppm is detected.

䚚

In this case, the zero-point compensation is not implemented.

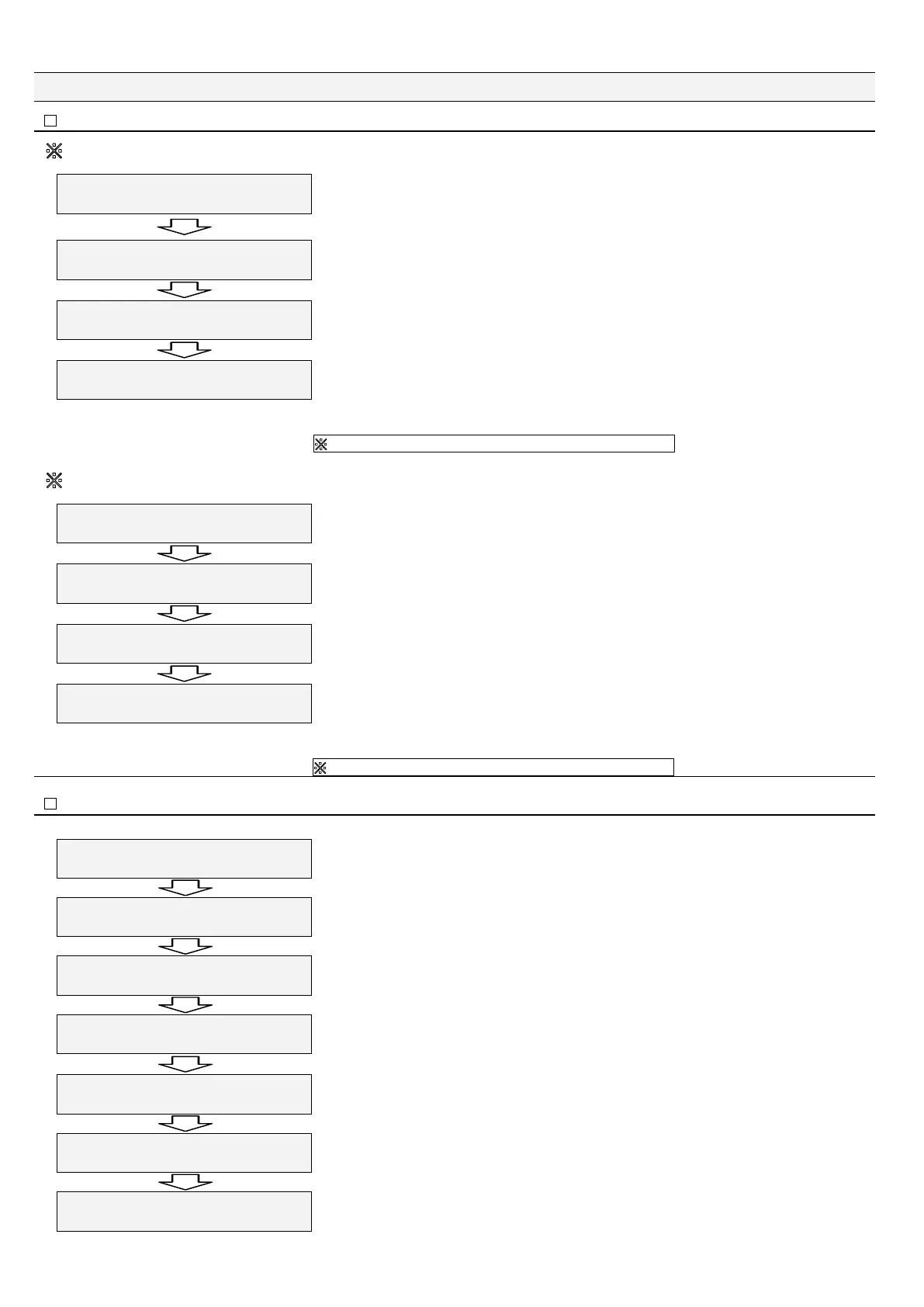

䚚B

The zero-point compensation is disabled when the detection tube is judged to be dirty (because oil or contaminant on the inside wall of the

detection tube cannot be flushed away by sensor cleaning) or when oil concentration over 5 ppm is detected in the zero-point compensation.

<GTQEQOR

9CTPKPIEGNN VQQ &KTV[

Displayed when the inside of the detection tube is dirty.

(In this display example, 10 ppm o 10 ppm)

To warn that the detection tube is dirty. Press "Enter.”

9CUJKPI'UESWKV

ZZZ

Opens the fresh water valve to flush fresh water into the detection tube to keep the performance of

the tube. The remaining flushing time is displayed on the lower right part of the screen.

/CKPVGPCPEG/QFG

2TGUUGPVGTVQEQPVKPWG

Press "Enter.”

/CKPVGPCPEG/QFG

<GTQCFLWUV0)QPGOQTG

On the next screen, you can select one of two methods. Press "Esc" to go back to "Main Menu"

or press "Enter" to retry the zero-point compensation. (It is recommended to turn off the oil

concentration detector and clean the sensor before retrying the zero-point compensation function.)

With this, the explanation is completed about the failure of the zero-point compensation when an oil concentration over

5 ppm is detected.

䚚

In this case, the zero-point compensation is not implemented.

䦟䎃 8-2-4.

Function for recovery after zero-point compensation (Recover press Enter)

Ɣ This function is used to reset the compensated value (compensated by "8-2-2 Zero-point compensation") to the initial value (not compensated).

5VCPFD[

ZZZZZZZZZZZZ

Keep on pressing "Esc" for two seconds or longer

㧷CKP/GPW

%NQEM#FLWUVOGPV

Press "Ÿ" three times.

㧷CKP/GPW

/CKPVGPCPEG/QFG

"Maintenance Mode" is set.

Press "Enter.”

/CKPVGPCPEG/QFG

9CUJKPIRTGUU'PVGT

Press "Ÿ" four times.

/CKPVGPCPEG/QFG

4GEQXGTRTGUUA'PVGT

Press "Enter.”

Resets the zero-point-compensated value to the previous value (before compensation).

/CKPVGPCPEG/QFG

4GEQXGTRTGUU'UE

Press "Esc.”

㧷CKP/GPW

/CKPVGPCPEG/QFG

"Main Menu" is displayed back.

With this, resetting to the uncompensated value is completed.

Loading...

Loading...