Festo Controller CECC

67

5 Diagnostics

5.1 General error behaviour

Warning

When an error occurs, the controller carries on the active program instead of stopping. Unwanted

actuator movements can cause collisions resulting in serious injury.

• Integrate error handling mechanisms for all error categories in the user program.

• Make sure that nobody enters the positioning range of the drives or other connected actuators.

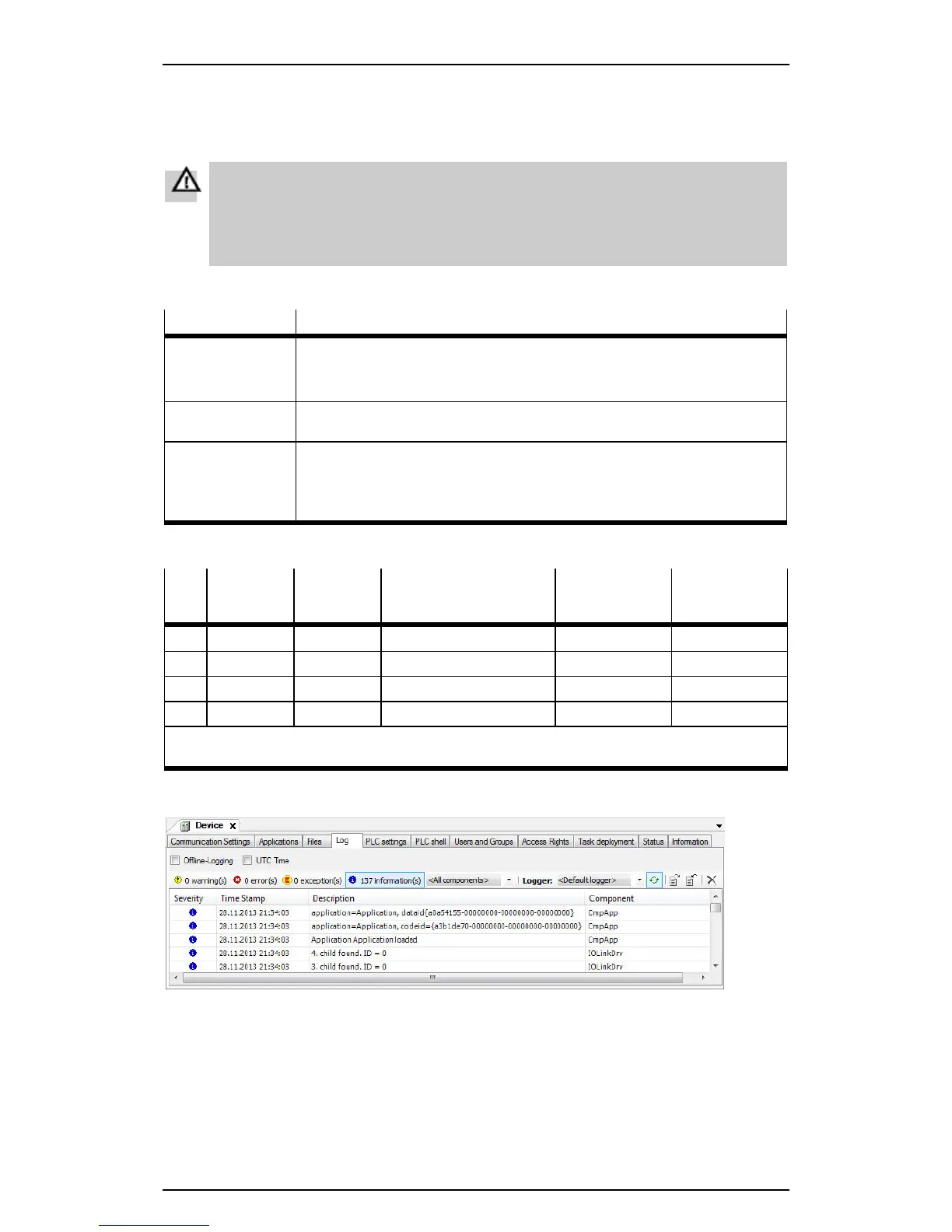

The following diagnostic options are available for the controller CECC:

Diagnostics via Advantages

Status LEDs Fast, local error detection using

– controller LEDs

– CECC-specific LEDs

Controller

configuration

Online diagnostics without programming

User program Detailed diagnostic evaluation:

– System event CECC_system_fault

– Support for function blocks from the Festo CECC_3 library section

"Diagnostics".

Table: Diagnostic options provided by the CECC

Error

class

Weighting Error no. Evaluation via function

block in

Festo CECC_3 library

Display in the

Codesys device

log

Display in the

FFT

1)

0 No error 0 X – –

1 Information 200 ... 255 X X X

2 Warning 1 ... 127 X X X

4 Error 128 ... 199 X X X

1) The Festo Field Device Tool (FFT) program can be downloaded via the Festo Support Portal

www.festo.com.

Table: Error evaluation options

Figure: Editing window with "Device" tab - "Log" sub-tab

Loading...

Loading...