10 / 17 Festo 7DNCBa_en

4 Repair steps

4.1 Preparation

• Before starting the repair, remove any attachments on the cylinder barrel, the bearing and end caps or the piston rod

(clamping device, end-position lock, etc) in accordance with the instructions in the accompanying operating instruc-

tions.

• Keep your working environment tidy.

• Only use the spare parts and assembly aids (grease, screw locking agent, etc.) provided in the wearing parts kit.

Warning

Make sure that the bearing cap cannot suddenly come ying off.

• Remove the non-return valves and tubing connection from the cylinder and depressurise the cylinder completely

so that any pressure present is not suddenly released when the cylinder is opened.

To prevent damage to sealing rims or guide surfaces, do not use pointed or sharp-edged assembly aids.

4.2 Visual inspection

Check the cylinder for visible damage that might impair its function (e.g. warping of the piston rod) as well as deposits

and scoring. The entire cylinder must be replaced if the cylinder barrel is showing signicant damage.

4.3 Repairing the cylinder DNCB-…

The description in this section can be used to repair cylinders of the type DNCB-… with the following features:

Code Description

PPV Adjustable pneumatic cushioning

A Position sensing

CT Free of copper, PTFE and silicone

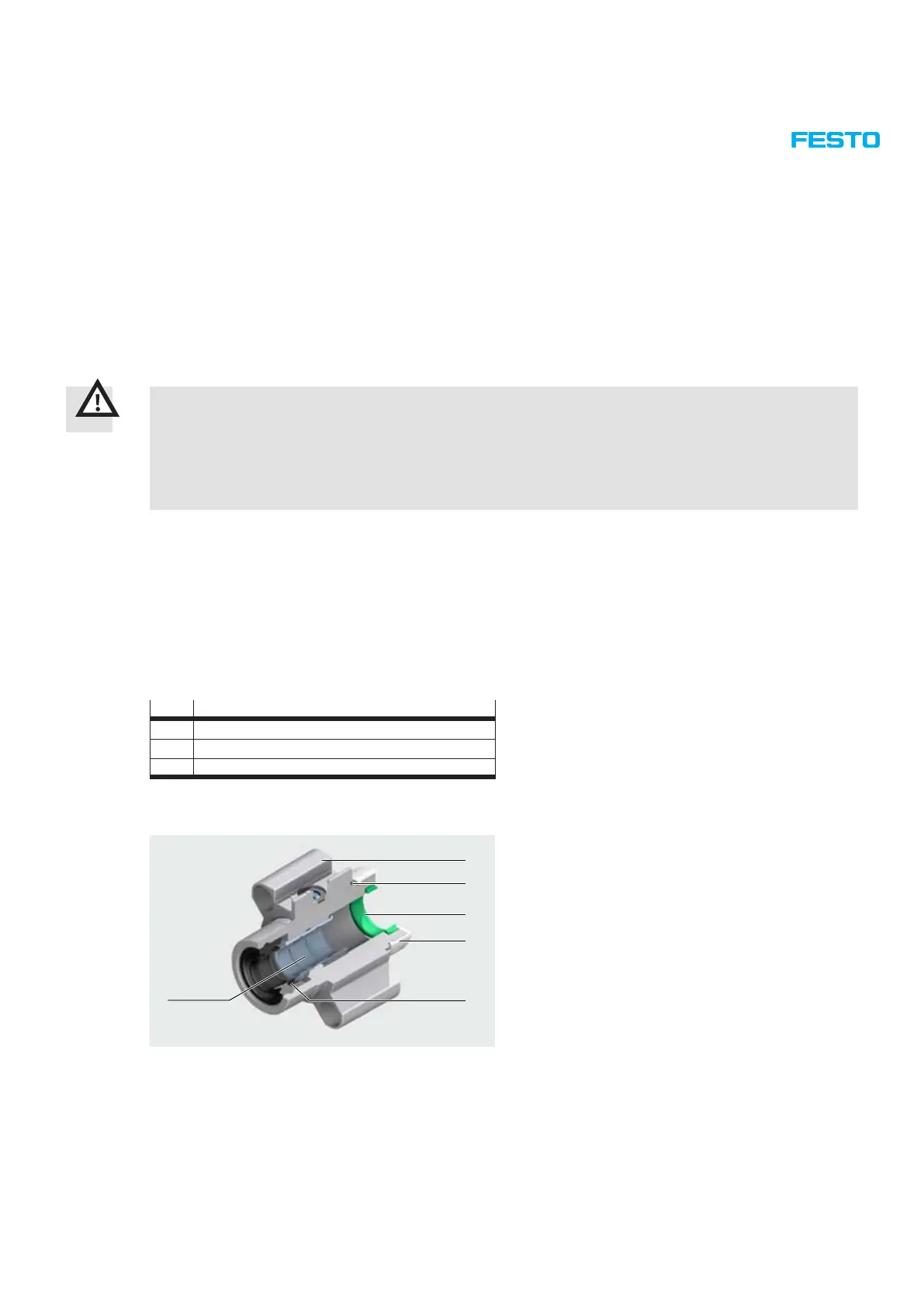

4.3.1 Structure of the bearing cap

1

2

4

5

6

3

1 Bearing cap

2 O-ring

3 Cushioning seal

4 Holding disc (only with DNCB-32/40/50/63-…)

5 Piston rod seal

6 Bearing

Loading...

Loading...