22

Fusion

Splicing Process

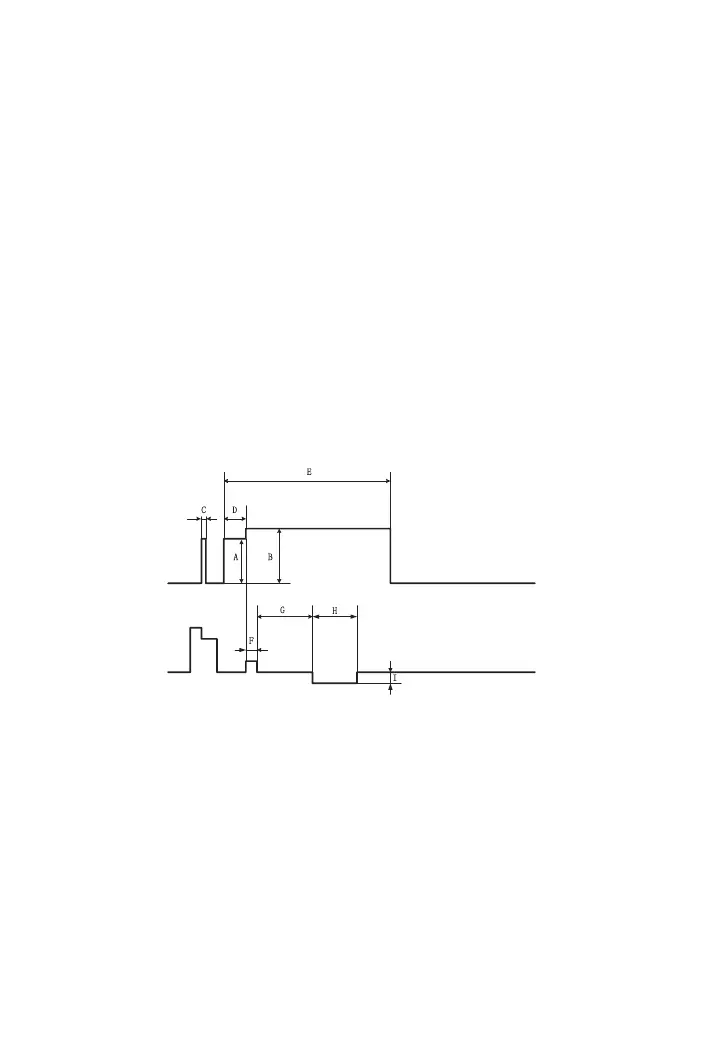

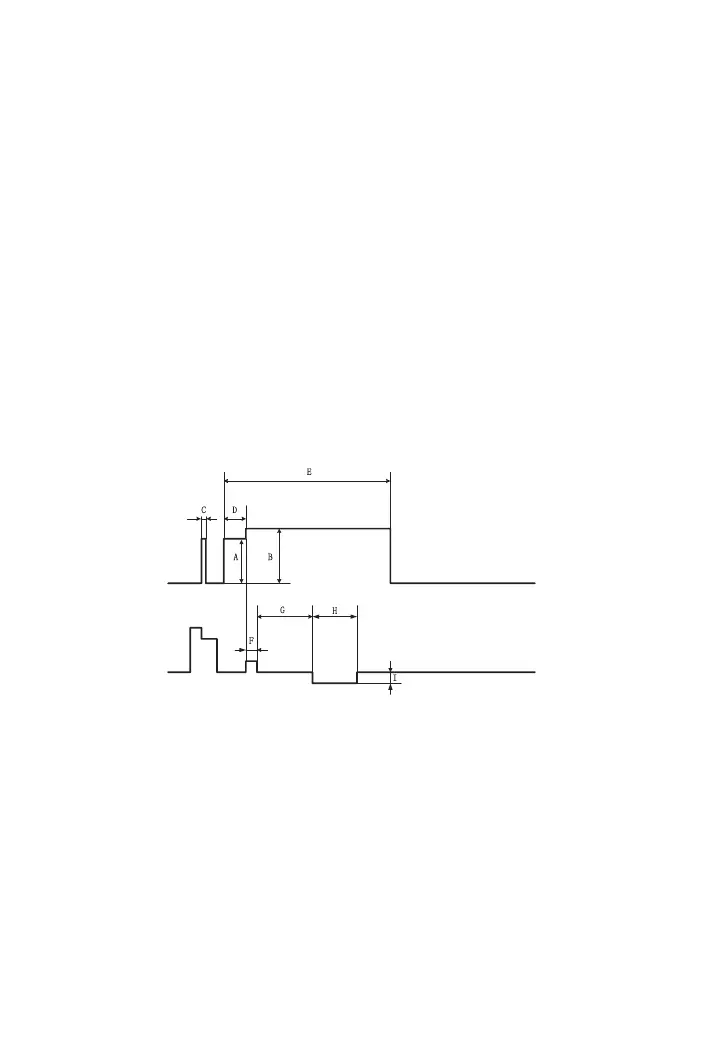

During fusion, the bers are joined together and subjected to ve dierent currents

as illustrated below. An important parameter, which changes during splicing, is

the distance between the bers. During Pre-fusion, the bers are apart. With the

current phase changing, bers are spliced gradually.

The most important splicing parameters are the time and current, each current

phase is shown below, that the name and function and other parameters are

important to the splice process are described under “Parameters for Normal

Splicing Process” on the next page.

The following gure shows the discharge conditions (The relationship between the

“discharge intensity" and "motor move"). We can change the splicing parameters

listed below to change the discharge conditions.

A: pre-fuse power B: Arc power C: cleaning Arc

D: pre-fuse time E: Arc time F: Overlap

G: Taper wait time H: Taper time related to taper length I: Taper speed

Diagram of ARC discharge condition

Loading...

Loading...