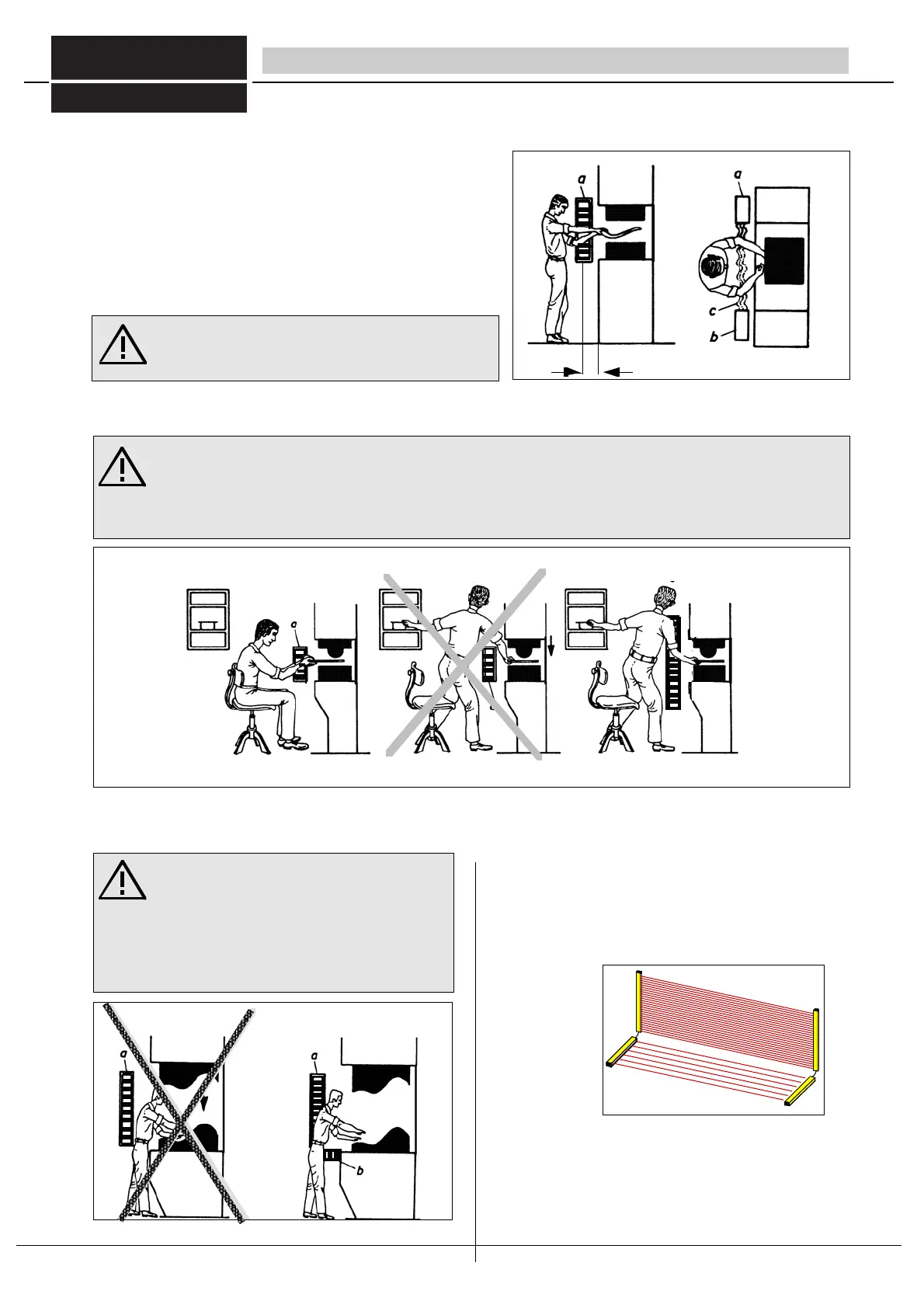

4.3.1 Installation without additional screening

The light transmitter (a) (Fig. 17/1) and the light receiver (b)

form the light barrier (c). If the light beams are interrupted, e.g. by

a hand, a pilot circuit is opened and the closing action is

prevented / stopped. In the opposite example, it is not possible

to avoid the ULVT light barrier from the working side, which

means that additional screening is not required.

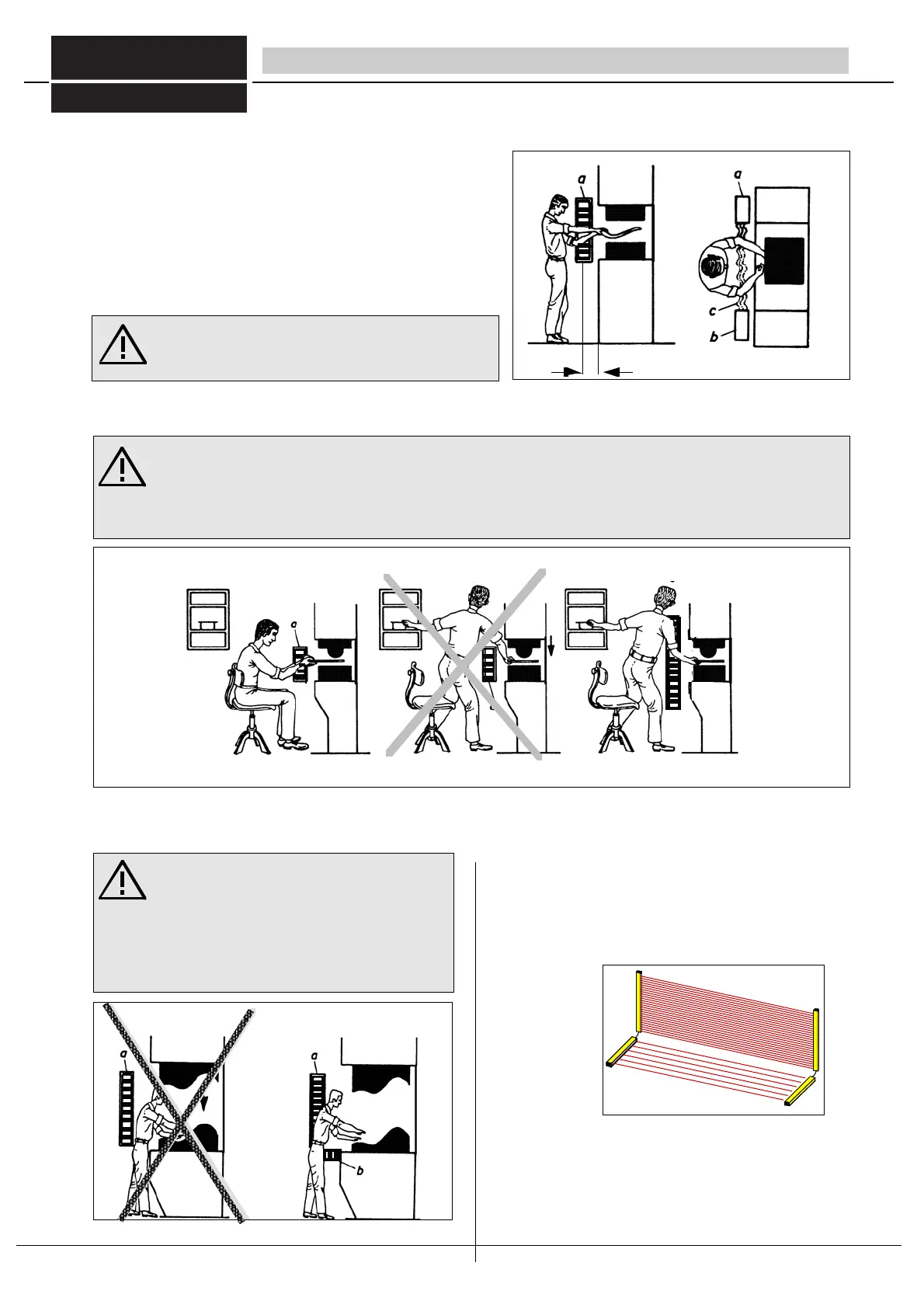

4.3.2 Protection against reaching under and over

4.3.3 Protection against walking behind through cascading or additional screening

4 Installation - Construction requirements

fig. 17/1 Installation without additional screening

fig 17/2a,b,c Protection against reaching under and over

17/2.a

17/2.b 17/2.c

fig 17/3 Protection against walking behind through cascading of two light barriers

In cascading, varying form factors can be combined

(e.g. main sensor with 1100 mm protective field height

and succeeding sensor with 200 mm protective field).

Please refer to

chapter 8.

fig 17/4 Cascading of two safety light curtains

In order to prevent the walking behind the protective

field, the distance between the ULVT/BLVT safety light

barrier and the machine must be _< 75 mm.

In a normal working process (Fig. 17/2a), the operator inserts the workpiece when sitting down. Due to the over-

run period of the machine, the ULVT/BLVT safety light barrier (a) is mounted slightly in front of the hazardous

area (refer to chapter 4.2). However, the light barrier height selected here leaves an unprotected gap at the top of

the light barrier. Fig. 17/2b shows how reaching over the light barrier can lead to an accident. The proper

rectification of this problem is illustrated in Fig. 172/2c, where a ULVT safety light barrier with a larger protective

field height has been attached.

If the distance between the vertical ULVT/BLVT

safety light barrier and the machine needs to be

greater than 75 mm (e.g. in order to maintain

the safe distance to the hazardous area), the

possibility of walking behind the protective field must be

eliminated through an additional ULVT safety light

barrier and/or cascading of two light barriers (Fig. 17/3 and

17/4) or a protective bar.

wrong!

correct!

correct!

FIESSLER

E L E K T R O N I K

wrong!

17

Fiessler Elektronik GmbH & Co. KG

Doku Nr. 958 Stand 22.01.2018 RK

Phone: +49 (0) 711 / 91 96 97-0 Internet: http://www.fiessler.de

Fax : +49 (0) 711 / 91 96 97-50 eMail: info@fiessler.de

Loading...

Loading...