Start interlock

Subsequent to commissioning and/or a power interruption, the start interlock prevents a "re-release". A re-release is only possible

once the protective field has been interrupted and reactivated.

Response time

The time period between penetration of the protective field and the switching process.

Blanking

Ther Balnking features provide the temporarily "skipping" or "disabling" of selected areas of the the protective field. By doing this,

parts of tools or machinery may reach into the protective field without reducing the function of the machine. (please refer top

chapter 7 BLVT).

EPSE Type 4

The ULVT/BLVT... safety light barriers comprise photo-electric guards. These devices are characterized by the fact that when the

protective field generated by the transmitter and receiver is interrupted, a hazardous movement is interrupted or prevented.

One-cycle (two-cycle operating mode)

Subsequent to one (two) penetrationsof the protectvie field, the machine automatically performs an operating cycle and then waits

for a maximum 30 seconds for one (two) penetrations.

If the time period exceeds 30 seconds, the restart interlock is activated.

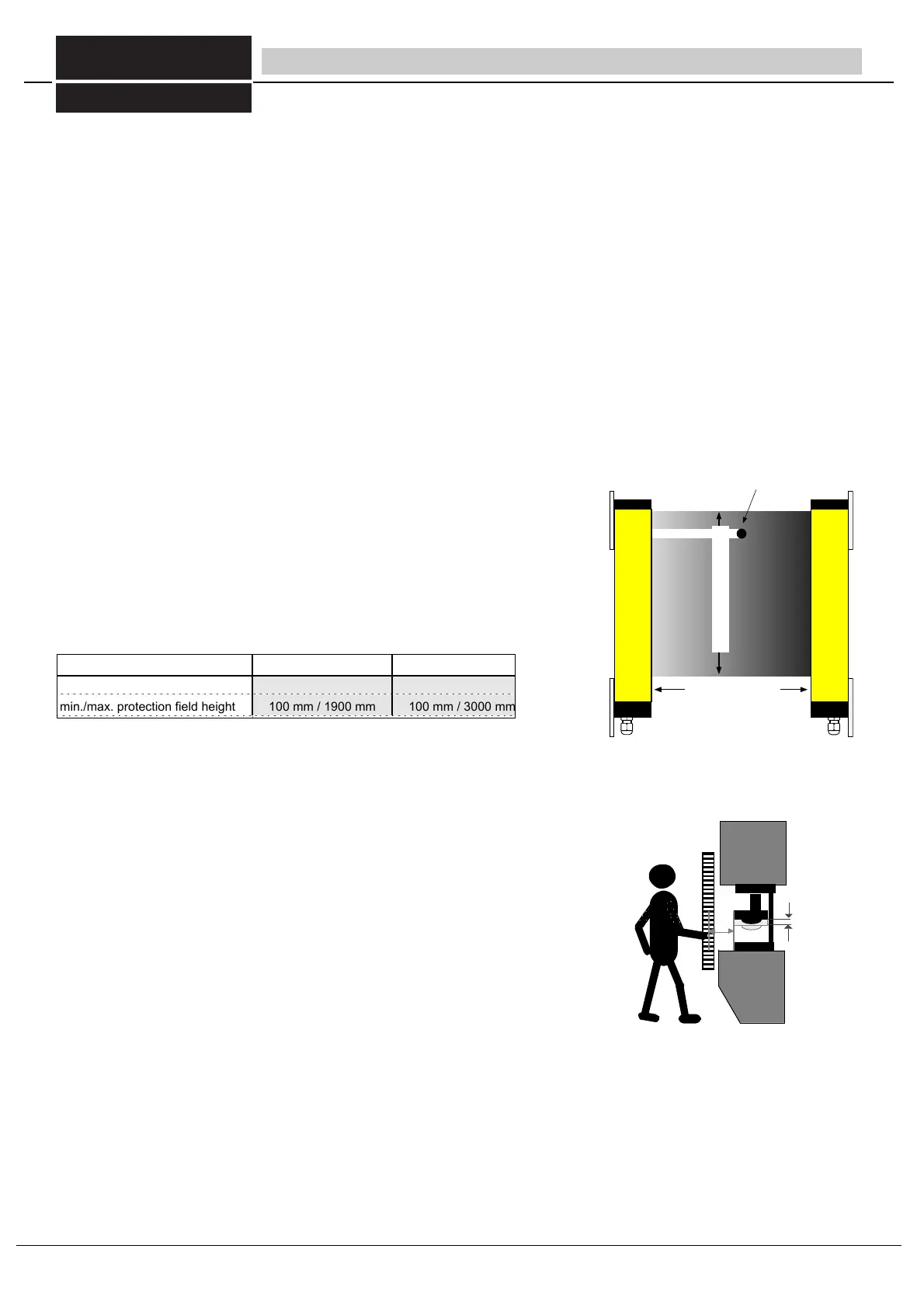

Installation range (Fig. 6/1)

The minimum and/or maximum permissible distance between the transmitter and

receiver. The permissible detection range is specified on the ULVT receiver.

Obstacle size (Fig. 6/1)

The obstacle size indicates the minimum obstacle diameter that will definitely interrupt a

hazardous movement through the safety light barriers.

The following obstacle sizes are provided by the beam distances for the ULVT... safety

light barriers:

Muting

Temporary and safe bridging of the ULVT/BLVT safety light barriers during a material movement, e.g. into and out of a

manufacturing cell, or in high-bay storage. Reliable differentiation between man and material flow is ensured.

Overrrun

The section of hazardous movement which occurs after penetration of the protective field.

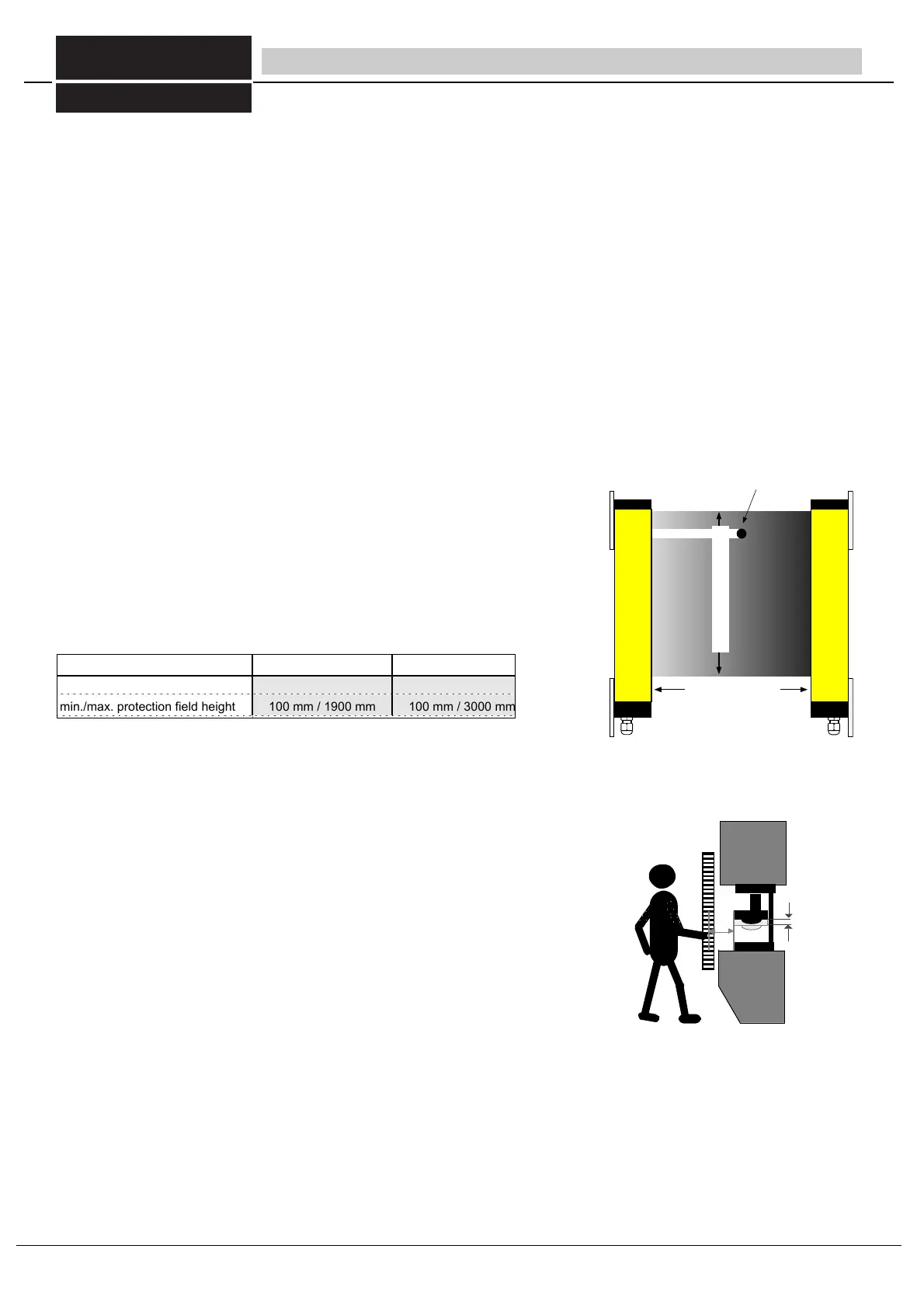

Overrrun traverse (Fig. 6/2)

The path traversed during the run-on period (e.g. path of a ram, path of a point on a roller

surface).

Overrrun period

Duration of the run-on period.

Protective field height (Fig. 6/1)

Height of the protective field generated by the transmitter and receiver.

Safety mode

When the protective field is interrupted, the switching outputs are blocked, then automatically released subsequent to re-release

of the protective field.

Self-monitoring

The automatic response of the photo-electric guard in the event of an internal malfunction.

Safety distance (Fig. 30/2)

The minimum distance S between safety light barrier and the nearest hazardous area, required in order to prevent injuries. In

order to establish the minimum safe distance, the formulas from standard EN 999 / ISO 13855, the machine-specific EC

standards and the effective ZH guidelines are to be used.

min./max. detection range 0,3 m / 7 m 0,3 m / 24 m

min. obstacle diameter

min./max. protection field height

14 mm

100 mm / 1900 mm

30 mm

100 mm / 3000 mm

2 Terminology

protective field height

detection range

obstacle diameter

Bild 6/2 Ssafety distance and overrun traverse

fig 6/1 detection range, obstsacle size, protective fied height

Table 6/1a detection range, obstsacle size, protective fied height

Overrun

traverse of

the machine

FIESSLER

E L E K T R O N I K

6

Fiessler Elektronik GmbH & Co. KG

Doku Nr. 958 Stand 22.01.2018 RK

Phone: +49 (0) 711 / 91 96 97-0 Internet: http://www.fiessler.de

Fax : +49 (0) 711 / 91 96 97-50 eMail: info@fiessler.de

Loading...

Loading...