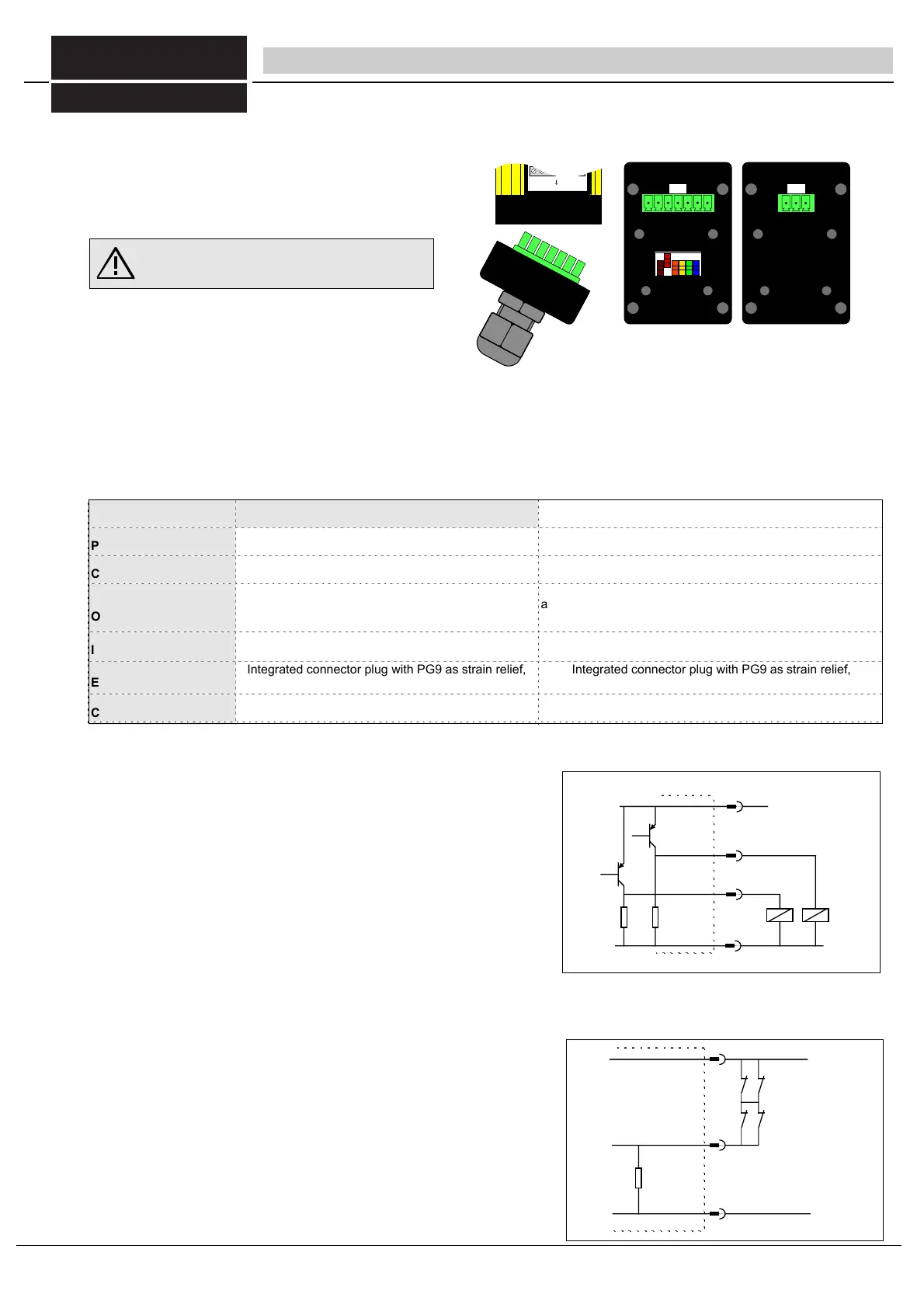

5.1 Integrated connector plug

The ULVT/BLVT construction series is supplied with PG

threaded joints as standard. Various conventional

connector plugs can also be obtained as optional

accessories.

The electric connection is implemented via terminal screws

in the connector cover (Fig. 25/1). The cover can be

removed once the 4 screws have been loosened.

The transmitter and receiver require a power supply of 24

V DC. The ULSG switchgear performs the power failure

bridging of 20 ms pursuant to EN 60204 and is thus suitable as the power supply for ULVT/BLVT light barriers. The receiver is

equipped with 2 inputs and 2 outputs. The transmitter is connected via one 3-pin cable and the receiver via one 5 to 7-pin

cable (depending on operating mode). The permissible cable cross-section is max. 1.5 mm2. The cables must be routed

separately from power lines.

5.2 Electric connection ratings

5.3 Connectors

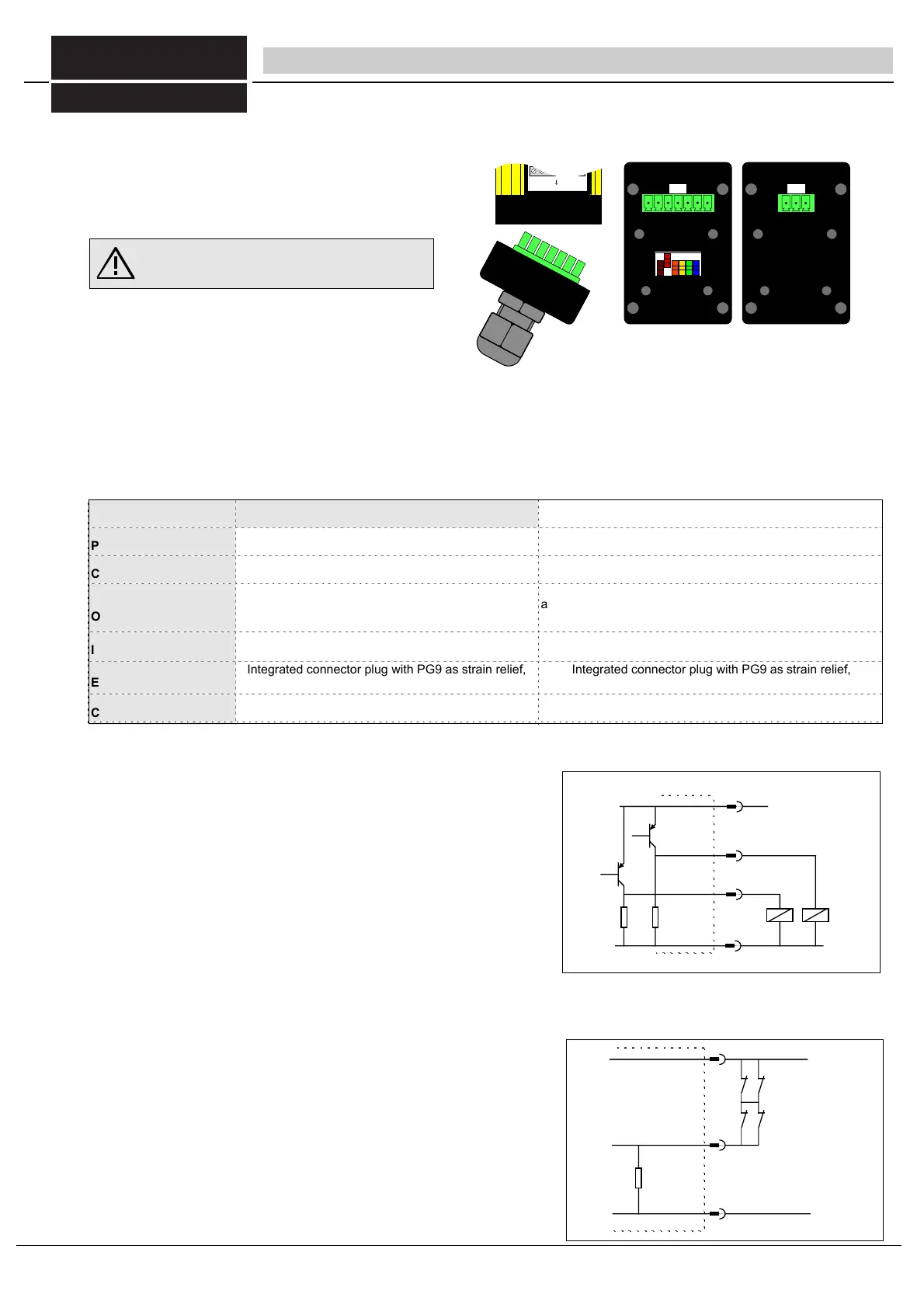

- Outputs 1 and 2 (OSSD 1 and OSSD 2)

The outputs are not potential-free and must not be switched in series

or parallel, but must be connected and processed separately!

In the operating mode with equivalent outputs, both PNP outputs are

failsafe and feature internal short-circuit and cross-circuit monitoring. Both

outputs are high (+24 V) when the light path is free.

In the operating mode with antivalent outputs, output 1 is high (+24 V)

and output 2 low (0 V) when the light path is free. Output 2 is not failsafe

in this operating mode. This operating mode is only permissible in

conjunction with the safety switchgears LSUW NSR 3-1K, LSUW N1-

Muting K, or another safe sequential phase control device which

monitors output 2!

- Input contactor check (EDM)

If the operating mode with contactor check is set, the auxiliary contacts

K1 and K2 of the driven contactors K1 and K2 must be connected to the

contactor check input in series and with +24 V as shown in Fig. 25/4.

The OSSD1 and OSSD 2 of the ULVT will only switch on the two contactors

when contactor check input has detected the idle status of the contactors (+

24 V at contactor check input).

Once the contactors have been driven, both of them must respond within

300 ms. The two auxiliary contacts must then be open (0 V at contactor

check input).

If the operating mode without contactor check is set, the input contactor

check must be unoccupied.

5 Electric connection - Connection of receiver and transmitter

The electric connection must only be carried

out when no voltage is present.

OSSD 2

OSSD 1

3

4

7

+24V DC±20%

0V

6

K 1 K 2

fig 25/3 outputs 1 and 2

0V

7

2

+24V DC±20%

Eingang Schützkontrolle

6

Hilfsöffner k1

Hilfsöffner k2

fig 25/4 input contactor control

123 4 56 7

3: OSSD1

5:

2: EDM

7: 24VDC

±20%

4: OSSD2

1: Start

123456

off

12 3456

7

1

2

3

6: 0V

fig. 25/1 Integrated connector plug with terminal screws in connector

cover Receiver 7-pin, transmitter 3-pin.

+24V DC± 20%

auxiliary contact k1

auxiliary contact k 2

input contactor control

Table 25/2 electri connection ratings

ULVTS/BLVTS transmitter ULVTE/BLVTE receiver

Power supply

Current draw

24 V DC, + 20% - 10%, SELV

max. 250 mA

24 V DC, ±20%, SELV

max. 250 mA (without load)

Outputs

Inputs

Electric connection

Connecting cable

-

-

OSSD 1 and 2: Failsafe PNP outputs,max. 0.5 A, short-circuit

and cross-circuit monitoring (in operating mode with antivalent

outputs, output 2 is a non-failsafe PNP output, max 20 mA

)

Inputs contactor check and start button:

0 V to 24 V DC _+ 20%, 10 mA

Integrated connector plug with PG9 as strain relief,

alternatively conventional connector plug.

Integrated connector plug with PG9 as strain relief,

alternatively conventional connector plug.

5 to 7-pin (depending on operating mode) max. 1.5 mm2

Protection category IP 65 IP 65

FIESSLER

E L E K T R O N I K

25

Fiessler Elektronik GmbH & Co. KG

Doku Nr. 958 Stand 22.01.2018 RK

Phone: +49 (0) 711 / 91 96 97-0 Internet: http://www.fiessler.de

Fax : +49 (0) 711 / 91 96 97-50 eMail: info@fiessler.de

Loading...

Loading...