FINEPLACER

®

lambda

Rev-Nr. 1.1

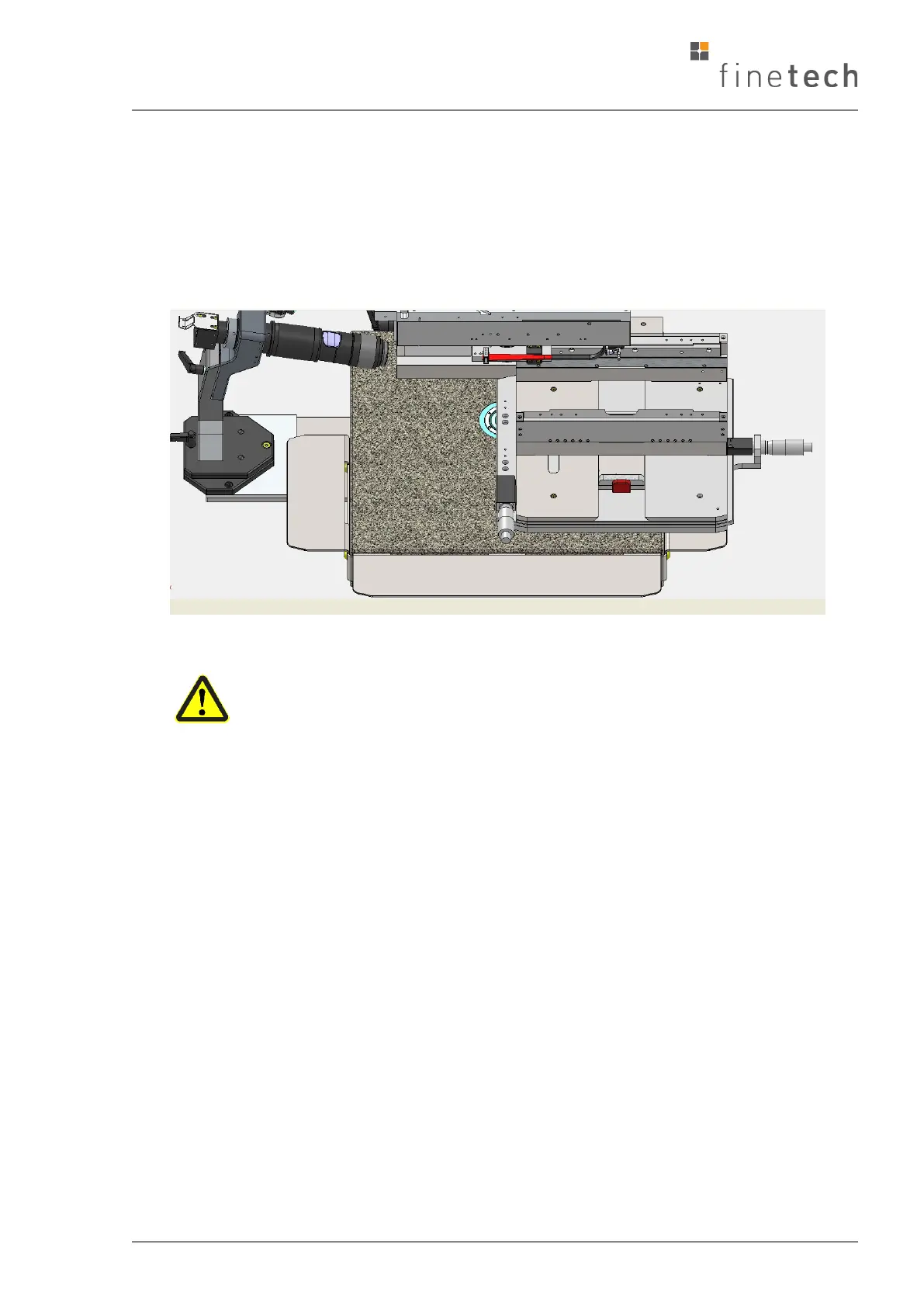

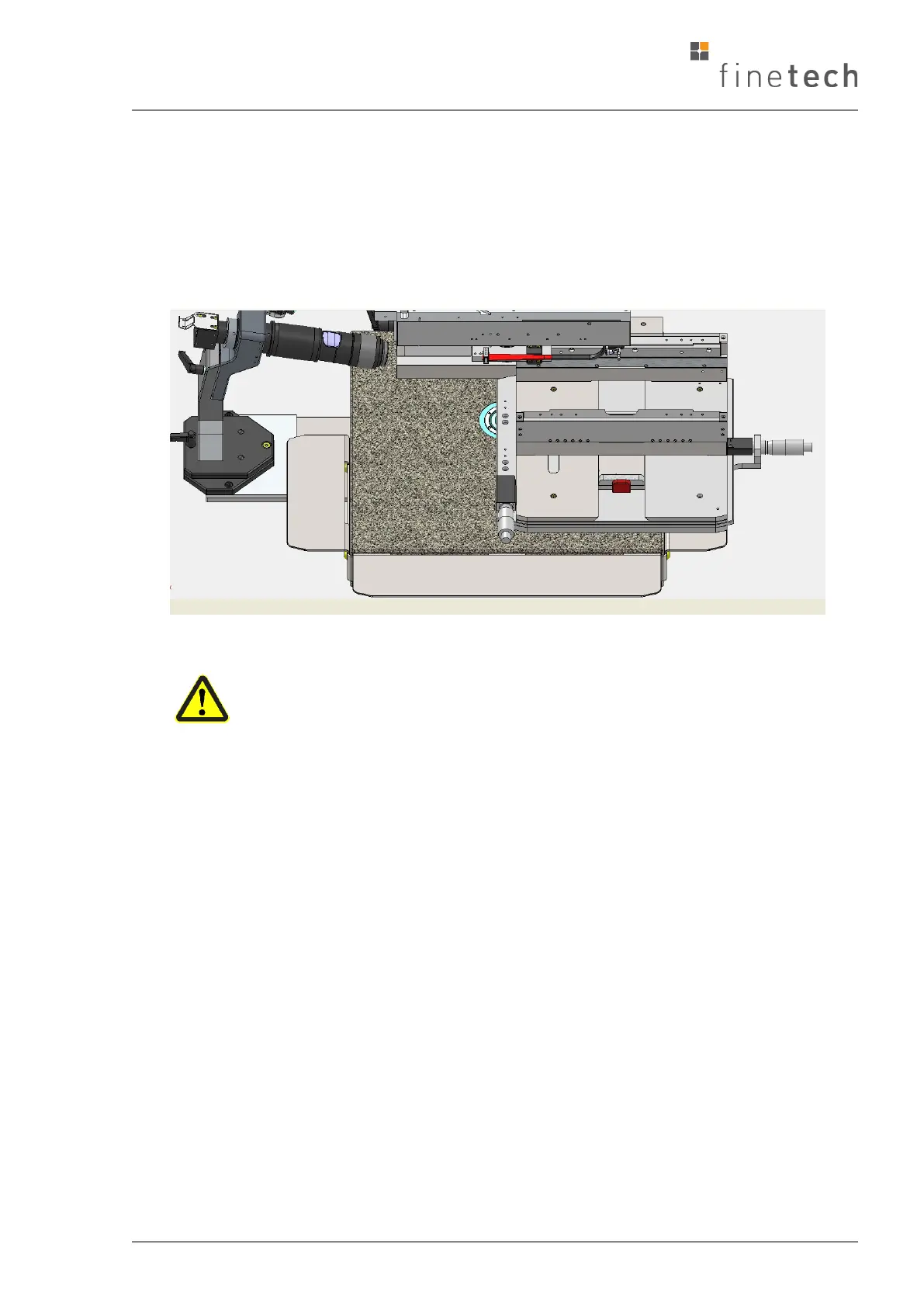

• Move the positioning table away from the operator towards the arm support and

then to the right. This time, the magnet inside the base plate will remain

covered by the table (see illustration). Turn off the machine. Clean the left side

of the base plate. Move the positioning table back to the center. Remove the

maintenance table support. Turn on the machine.

Damage can occur here due to incorrect behaviour of the operator (by

leaning or putting weight on the table).

6.1.3 Daily

• Keep the base plate clean at all times. Do not allow dust or particles to collect

on the underside of the positioning table. Wipe with a soft cloth, remove built-

up flux deposits using the minimum amount of the proper solvent; (wiping

with a bare hand may help you to decide about cleanliness). Dust the

remaining subassemblies as required.

• Failure to keep the FINEPLACER

®

clean, or damage of the sliding planes may

result in needless calibration, or difficulty in placing devices on the boards.

• Take care that the vacuum nozzles of the pipette and pivot arm do not suck in

dirt, flux, or fumes. Do not operate the vacuum devices without the vacuum

filter in the head vacuum socket (46) to avoid damage to the internal pump

and magnet valves.

• Check whether the vacuum can safely hold your critical or expensive

component. Change suction cups, gaskets, vacuum pump if required, protect

hoses from being stepped on, driven over, crushed, cut, split etc. See spare

part list for purchasing codes.

Right-hand maintenance position of the table

Left-hand maintenance position of the table

Loading...

Loading...