Types 1098-EGR and 1098H-EGR

10

Supply the boiler pilot light gas with the Type 1098-EGR.

The pilot light gas supply line should branch off the

main fuel line downstream of the Type 1098-EGR and

include a separate regulator to control the nal pilot

light gas pressure, if required (see Figure 5). This

allows the Type 1098-EGR to have its main valve plug

just off the seat waiting for the sudden negative shock

created when the boiler solenoid valve is opened to

light the boiler to the low re load. This installation

practice signicantly increases the stroking speed of

the Type 1098-EGR. See Figure 5 for schematic.

SIZE CONSTRUCTION ORIFICE SPRING RANGES

SPRING

NUMBER

SPRING

COLOR

MINIMUM PRESSURE

AT WHICH AUXILIARY

PILOT CAN BE SET

3/4-inch

(19 mm)

Type Y600AM

1/2-inch

(13 mm)

4 to 8-inches w.c. (10 to 20 mbar) 1B653827052 Red

1-inch w.c. (2 mbar) Under

working pilot setpoint

7 to 16-inches w.c. (17 to 40 mbar) 1B653927022 Olive Drab

15-inches w.c. to 1.2 psi (37 mbar to 0,08 bar) 1B537027052 Yellow

Type Y600AM

1/2-inch

(13 mm)

1.2 to 2.5 psi (0,08 to 0,17 bar) 1B537127022 Light Green

0.2 psig (0,01 bar) Under

working pilot setpoint

2.5 to 4.5 psi (0,17 to 0,31 bar) 1B537227022 Light Blue

4.5 to 7 psi (0,31 to 0,48 bar) 1B537327052 Black

Type 627M

1/2-inch

(13 mm)

5 to 10 psi (0,35 to 0,69 bar) 10B3076X012 Yellow

0.3 psig (0,02 bar) Under

working pilot setpoint

Table 6. Auxiliary Pilot Selection (Fast Stroke Dual Pilot)

Note

Modulating solenoid load valves provide

one position to the other, effectively

preventing sudden pressure changes in

the system. Alternately, a snap-acting

solenoid valve can be furnished with a

characterized valve plug that, by allowing

maximum capacity to be reached at a

greater proportion of total travel, slows

the action slightly. This action does

not control shock as effectively as

modulating solenoid valves.

Installation

1. Perform the Standard Single-Pilot Regulator

Installation section through step 3, making sure

that the regulator is installed with the actuator

below the main valve as shown in Figure 4.

2. Run a 1/2-inch (13 mm) or larger pilot supply

line from the upstream pipeline to the 1/2-inch

NPT supply connection in the pipe tee as shown

in Figure 4. Do not make the connection in a

turbulent area, such as near a nipple, swage, or

elbow. If the maximum pilot inlet pressure could

exceed the pilot rating, install a separate regulator

in the pilot supply line, and provide vent valves so

that pressure can be properly isolated and relieved

from the regulator.

3. Attach a 1/2-inch NPT downstream

pressure control line ten pipe diameters

downstream of the regulator in a straight run

of pipe. Do not make the tap near any elbow,

swage, or nipple, which might cause turbulence.

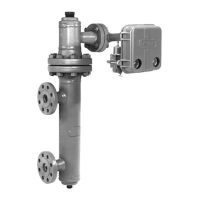

E0711

Figure 5. Boiler Fuel Conguration

TYPE 1098-EGR SIZE 70

WITH QUICK OPENING CAGE

20 PSI (1,4 bar) MAXIMUM

TYPE Y600AM

AUXILIARY PILOT

TYPE 6352

WORKING PILOT

Loading...

Loading...