Types 1098-EGR and 1098H-EGR

20

procedure steps 1 and 4, and pull the stem

(key 14) out of the diaphragm casing (key 4).

Grease the replacement stem O-ring (key 30,

Figures 21 and 22) with a good grade of lubricant

and install it on the stem (key 14).

5. Install the stem (key 14) into the diaphragm

casing (key 4) and perform Body Area

Maintenance procedure steps 6 through 8

as necessary.

6. Install the lever assembly (key 16) into the stem

(key 14) and secure the lever assembly with the

machine screws (key 17).

7. Hold the pusher post (key 8) and place diaphragm

assembly parts on the pusher post in the following

order: diaphragm (key 10), diaphragm head

(key 7), lower spring seat (key 50), and washer

(key 36), and secure with diaphragm cap screw

(key 38) using 7 to 9 foot-pounds (9 to 12 N•m)

of torque.

8. Install the pusher post (key 8) and attached parts

onto the lever (key 16).

9. Install the control spring (key 6) and spring case

(key 3) on the diaphragm casing (key 4) so that the

vent assembly (key 26) is correctly oriented, and

secure them with the cap screws (key 24) and hex

nuts (key 23) to nger tightness only.

10. Turn the adjusting screw (key 35) clockwise

until there is enough control spring (key 6) force

to provide proper slack to the diaphragm

(key 10). Using a crisscross pattern, nish

tightening the cap screws (key 24) and hex nuts to

5 to 6 foot-pounds (6,8 to 8,1 N•m) of torque. Finish

turning the adjusting screw to the desired outlet

pressure setting.

11. Install the closing cap (key 22).

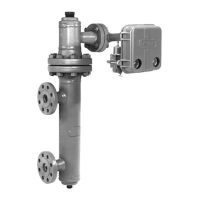

Type 95H Supply Pressure Regulator

This section includes instructions for disassembly and

assembly of replacement parts. All key numbers refer

to Figure 24.

1. Unscrew the valve plug guide (key 5) from the

body (key 1). The valve plug spring (key 10) and

the valve plug (key 4) will normally come out of

the body along with the valve plug guide.

2. Inspect the seating surface of the valve plug,

being sure that the composition surface (or

polished steel surface) of the valve plug is not

damaged. Replace if damaged.

3. Inspect the seating edge of the orice (key 3).

If damaged, unscrew the orice from the body

and replace it with a new part. If no further

maintenance is required, reassemble the

regulator in the reverse of the above steps. When

installing the valve plug guide (key 5) coat the

threads and sealing surface with sealant to ensure

an adequate metal-to-metal seal.

4. To inspect the diaphragm (key 12) or other

internal parts, loosen the locknut (key 17) and

turn the adjusting screw (key 15) to remove all

spring compression.

5. Remove the diaphragm case cap screws

(key 16) and lift off the spring case (key 2).

Remove the upper spring seat (key 9) and

regulator spring (key 11). Remove the lower

spring seat (key 8).

6. Remove the diaphragm (key 12) and examine for

damage. Replace if damaged.

7. With diaphragm removed, check to be sure the

pressure registration hole is completely open and

free of all obstructions.

8. Reassemble in reverse order of the previous

steps. Lubricate the upper spring seat (key 9)

and the exposed threads of the adjusting screw

(key 15). Before tightening cap screws (key 16)

be sure to install the adjusting screw, if completely

removed, and turn it down to obtain diaphragm

slack. This allows proper positioning of the

diaphragm to permit full travel of the valve plug

(key 4). Complete reassembly procedures and

temporarily install a gauge in place of the pipe plug

(key 52). Turn the adjusting screw to produce the

desired outlet pressure values shown in Table 2.

Tighten the locknut to maintain the desired setting.

Types 1098 and 1098H Actuator and Pilot

Mounting Parts

Perform this procedure if changing the actuator

or inspecting, cleaning, or replacing actuator

and/or pilot mounting parts. Actuator part key

Loading...

Loading...