Types 1098-EGR and 1098H-EGR

9

Startup

1. Slowly open the pilot supply line hand valve.

2. Slowly open the upstream block valve and

partially open the downstream block valve for

minimum ow. Slowly open the hand valve in the

control line.

3. Adjust the pilot setting, if necessary.

4. Completely open the downstream block valve.

5. Slowly close the bypass valve, if any.

Dual-Pilot Boiler Fuel Control

Applications

Boiler Fuel Pressure Control

To enhance proper operation and adequate response

to negative pressure shock condition in low differential

pressure boiler fuel control applications, use the

Type 1098-EGR boiler fuel conguration:

• Type 1098-EGR with Type 6352 pilot

• Size 70 Actuator

• Quick Opening Cage

• Yellow Main Spring

• Type Y600AM or 627M Auxiliary Pilot mounted in

parallel with the Type 6352 pilot

To provide faster response, two pilots mounted

in parallel sense downstream pressure. To provide

faster response, two pilots mounted in parallel sense

the downstream pressure. The Type 6352 pilot is

the primary controlling pilot and the Type Y600AM

or 627M auxiliary pilot stands by until it senses a

negative pressure shock condition. The auxiliary

pilot opens, allowing additional ow into the actuator,

increasing the stroking speed and providing faster

response. See Figure 5 for schematic. The quick

opening cage allows maximum capacity at shorter

travels to decrease stroking time in opening and

closing directions. The service conditions should not

exceed 20 psig (1,4 bar) maximum inlet pressure and

10 psid (0,69 bar d) maximum differential pressure.

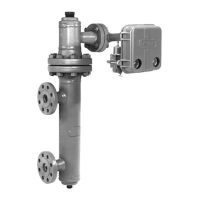

Figure 4. Typical Dual-Pilot Boiler Fuel Installation

48A6566-A

B1622

TYPE 1098-EGR REGULATOR WITH

STANDARD TYPE 6352 WORKING PILOT

CONTROL

LINE

1/2-INCH

(13 mm)

PIPE

TO PILOT

LIGHT

PILOT

SUPPLY LINE

1/2-INCH

(13 mm)

PIPE

VENT

FILTER

TYPE Y600AM

AUXILIARY PILOT

VENT

4 MAIN PIPE DIAMETERS

10 MAIN PIPE DIAMETERS

Loading...

Loading...