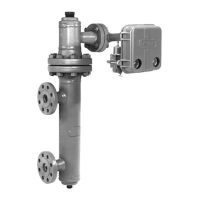

Types 1098-EGR and 1098H-EGR

11

Connect the other end of the control line to the

1/4-inch NPT connection in the control

pipe tee as shown in Figure 4. Install a hand

valve in the control line to shutoff the control

pressure when the bypass is in use. Also use

the hand valve to dampen out pulsations, which

may cause instability or cycling of the regulator.

4. Consult the appropriate instruction manual

for installation of an optional pneumatic or

electric remote control drive unit. For optional

remote pneumatic loading of a 6350 or

61 Series pilot, make the loading piping

connections to the 1/4-inch NPT vent connection.

Startup

1. Slowly open the pilot supply line hand valve.

2. Slowly open the upstream block valve and partially

open the downstream block valve for minimum ow.

3. Slowly open the hand valve in the control line

and make sure that the standby pilot is set

far enough below the working pilot so that

the standby pilot remains closed during normal

operation. For example, with nal desired settings

of 11-inches w.c. (27 mbar) for the working pilot

and 10-inches w.c. (25 mbar) for the standby

pilot, begin by reducing the working pilot setting

far enough below 10-inches w.c. (25 mbar) for

the working pilot to shutoff. Then set the standby

pilot for an outlet pressure of 10-inches w.c.

(25 mbar). Finally, set the working pilot for an

outlet pressure of 11-inches w.c. (27 mbar).

Table 6 shows how close the standby pilot can be

set to the working pilot setting.

4. Completely open the downstream block valve.

5. Slowly close the bypass valve, if any.

Working Monitor (Figure 7)

Installation

1. For both working monitor regulator and

working regulator, perform the Standard Single-

Pilot Regulator Installation section through step 6.

2. Connect another downstream pressure control

line and hand valve (Figure 7) to the monitoring

pilot according to the monitoring pilot instruction

manual. Attach a 1/2-inch NPT pressure control

line and hand valve from the intermediate

pressure pipeline to the working monitor regulator.

Pipe supply pressure between the monitoring pilot

and the working monitor regulator according to the

monitoring pilot manual.

For two typical monitoring pilots, Table 7 gives

the spread between normal distribution pressure

and the minimum pressure at which the working

monitor regulator can be set to take over if the

working regulator fails to open.

Startup

SAFTEY SHUTOFF VALVE

TO BOILER

FAST-ACTING

LOAD VALVE

TYPE

1098-EGR

GAS

SUPPLY

PILOT

GAS

SUPPLY

PILOT GAS

REGULATOR

TO PILOT LIGHT

E0710

Figure 6. Boiler Fuel Conguration Installation Guide

MONITORING PILOT INFORMATION

MINIMUM PRESSURE AT WHICH

WORKING MONITOR

REGULATOR CAN BE SET

Construction Spring Range Spring Part Number

Type 161AYW and 150 psig (10,3 bar)

maximum allowable pilot inlet

3 to 12-inches w.c.

11 to 25-inches w.c.

(7 to 30 mbar)

(27 to 62 mbar)

1B653927022

1B537027052

3-inches w.c. (7 mbar) over normal

distribution pressure

0.9 to 2.5 psi

2.5 to 4.5 psi

4.5 to 7.0 psi

(0,06 to 0,17 bar)

(0,17 to 0,31 bar)

(0,31 to 0,48 bar)

1B537127022

1B537227022

1B537327052

0.5 psig (0,03 bar) over normal

distribution pressure

Type 627-109 and 150 psig

(10,3 bar) maximum allowable pilot

inlet for cast iron body or 750 psig

(51,7 bar) maximum allowable pilot

inlet for malleable iron or steel body

5 to 20 psig

15 to 40 psig

35 to 80 psig

(0,34 to 1,38 bar)

(1,0 to 2,8 bar)

(2,4 to 5,5 bar)

10B3076X012

10B3077X012

10B3078X012

3.0 psig (0,21 bar) over normal

distribution pressure

70 to 150 psig

130 to 200 psig

(4,8 to 10,3 bar)

(9,0 to 13,8 bar)

10B3079X012

10B3079X012

5.0 psig (0,34 bar) over normal

distribution pressure

Table 7. Working Monitor Performance

Loading...

Loading...