Types 1098-EGR and 1098H-EGR

15

for damage during normal operation by line pressure

leakage or unexpected grease extrusion from the

actuator vent (key 27, Figure 14). All O-rings, gaskets,

and seals should be lubricated with a good grade of

general-purpose grease and installed gently rather

than forced into position. Be certain that the

nameplates are updated to accurately indicate any eld

changes in equipment, materials, service conditions, or

pressure settings.

!

WARNING

To avoid personal injury resulting

from sudden release of pressure,

isolate the regulator from all pressure

and cautiously release trapped

pressure from the regulator before

attempting disassembly.

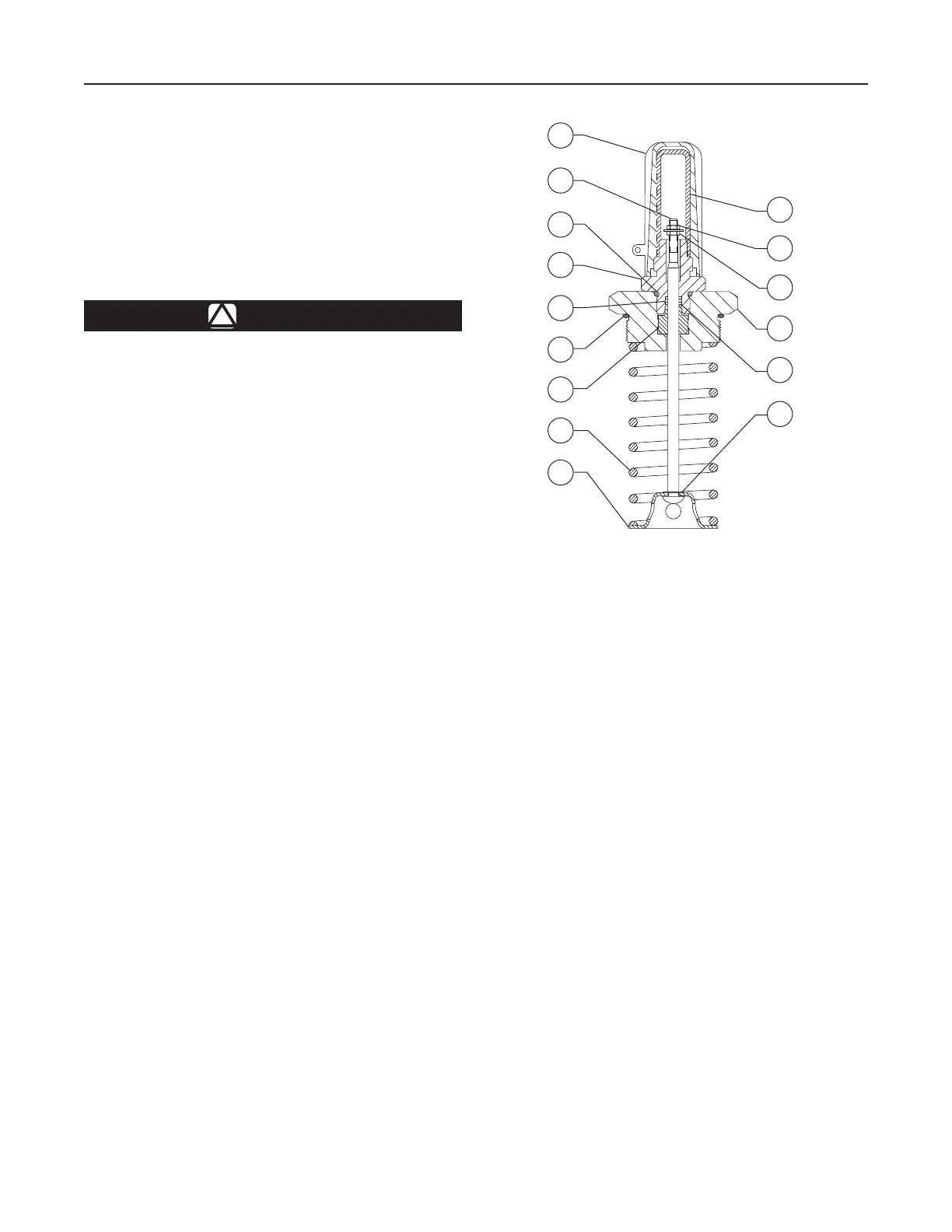

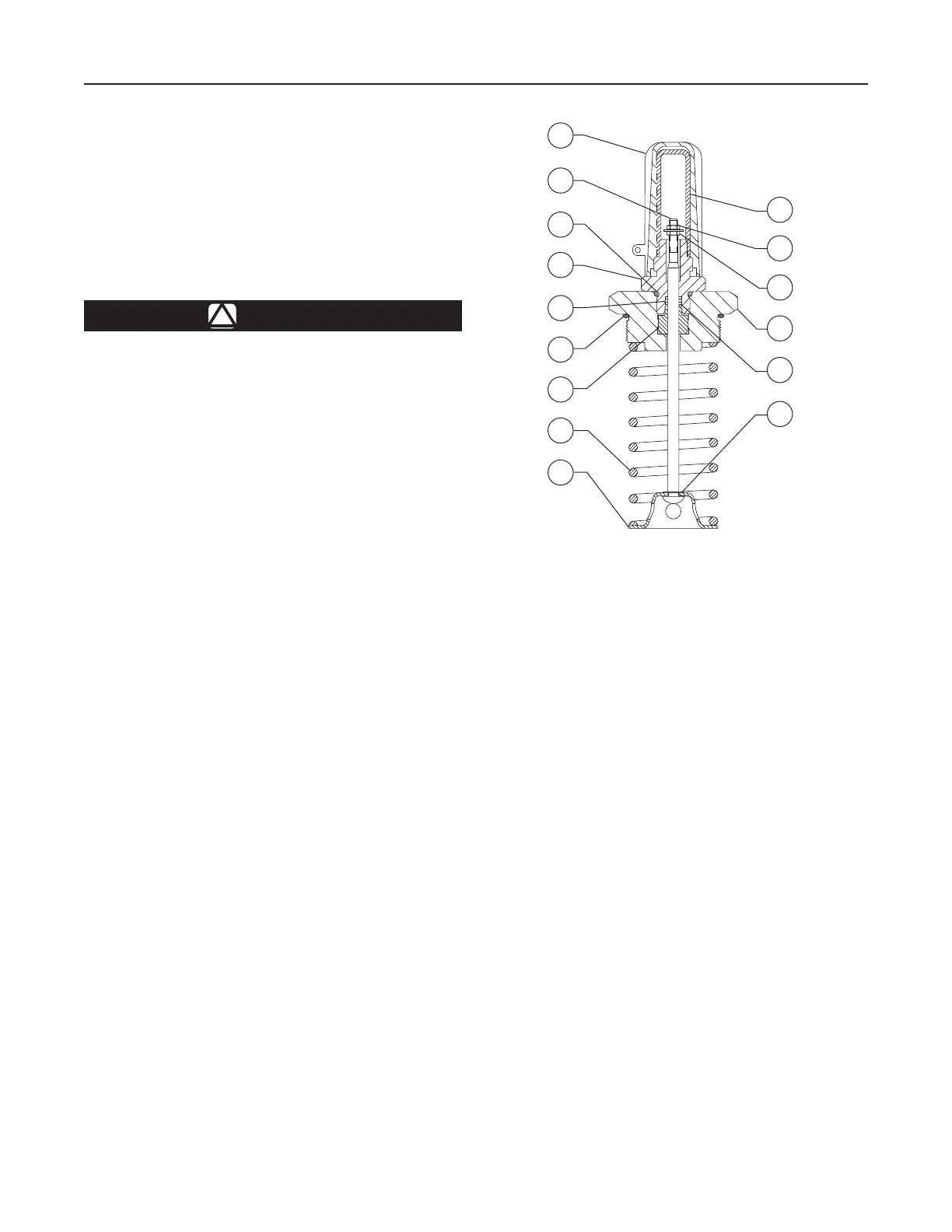

Design Type EGR Main Valve

Replacing Quick-Change Trim Package

Perform this procedure if the entire trim package

is replaced. Key numbers for both the complete

main valve and its trim package are referenced in

Figures 12 and 13. Some replacement trim package

assembly numbers are listed in a table in the parts list.

Note

All disassembly, trim change, and

reassembly steps in this section may be

performed with the regulator in the main

line and without disconnection pilot

supply or control lines.

1. Remove the cap screws (key 3) with a cast iron

body or remove the hex nuts (key 29, not

shown) with a steel body. Pry the body ange

(key 2) from the valve body (key 1) and lift out the

trim package.

2. Perform any required inspection, cleaning, or

maintenance on the exposed surfaces of the valve

body or trim package. Replace the gasket (key 4)

or cage O-ring (key 17) as necessary.

3. On a pre-built replacement trim package, check

indicator zeroing by unscrewing the indicator

protector (key 19) and seeing if the ange of

10C1212

Figure 11. Types 1098-EGR and 1098H-EGR Travel

Indicator Assembly

the indicator nut (key 22) lines up evenly with

the bottom marking on the indicator scale

(key 18). If not, remove the indicator scale

and separate the indicator nut and hex nut

(key 8). Hold the indicator scale against

the indicator tting (key 5) with the scale base

resting against the shoulder of the tting, and

turn the indicator nut until its ange is aligned

with the bottom scale marking. Then lock both

nuts against each other, and install the indicator

scale and protector.

4. Coat the cage seating surface of the valve body

web and the body ange seating surfaces of the

valve body neck with a good grade of general-

purpose grease. Install the trim package, and

secure it evenly with the cap screws or stud

bolt nuts.

No particular trim package orientation in the body

is required.

19

10

37

35

7

21

6

9

28

23

36

5

8

22

18

Loading...

Loading...