Types 1098-EGR and 1098H-EGR

6

actuator and main valve body, while the pilot control

spring range is displayed on the pilot spring case, and

the pilot restriction code is stamped on the pilot body

(S = standard gain, L = low gain, and H = high gain).

Principle of Operation

The pilot-operated Types 1098-EGR and 1098H-EGR

regulators both use inlet pressure as the operating

medium, which is reduced through pilot operation to load

the actuator diaphragm. Outlet or downstream pressure

opposes loading pressure in the actuator and also

opposes the pilot control spring. The Type 1098-EGR

regulator operation schematic is shown in Figure 2.

In operation, assume that outlet pressure is below

the pilot control setting. Control spring force on

the pilot diaphragm thus opens the pilot valve plug

providing additional loading pressure to the actuator

diaphragm. This loading pressure forces the actuator

stem forward, opening the main valve plug via a bump

connection. The upward motion of the plug allows gas

to ow through the cage into the downstream system.

When downstream demand has been satised, outlet

pressure tends to increase, acting on the pilot and

actuator diaphragms. This pressure exceeds the pilot

control spring setting, moving the pilot diaphragm away

and letting the valve plug spring (Type 6351, 61 Series, or

Y600AM pilots) or bellows (Types 6352 through

6354M pilots) close the pilot valve plug (unbalanced in the

Type 6351 or 61 Series pilots but balanced in the

Types 6352 through 6354M pilot). Excess loading

pressure on the actuator diaphragm escapes downstream

through the bleed hole (Type 6351 pilot), bleed orice

(61 Series pilot), restriction (Types 6352 through

6354M pilots) or xed restrictor (Type Y600AM pilot).

Reduced actuator loading pressure permits the main

valve to close. The combination of main valve spring

force and valve plug unbalance provides positive valve

plug shutoff against the port and upper seals.

To protect the Type 1098 or 1098H actuator diaphragm

from excessive differential pressure, the 6300 Series

pilots have a relief valve that allows loading pressure to

bleed downstream at approximately 25 psig (1,7 bar)

differential across the actuator diaphragm. An external

relief valve (Type 1806) is required when differential is

higher than 25 psid (1,7 bar d) or when using the

61 or Y600A Series pilots.

40 PSI (2,8 bar) Relief Valve

A mounting assembly for a 40 psi (2,8 bar) differential

relief valve is available for the Type 1098-EGR. The

standard 25 psi (1,7 bar) differential relief valve

construction is integrally mounted between the loading

and downstream pressures in the 6351 through

6354 Series regulating pilots. Both differential relief

valves protect the main regulator diaphragm from

damage that may occur from too high differential

between the loading pressure and downstream pressure.

The 40 psi (2,8 bar) differential relief valve construction

is designed specically for the red main valve spring

selection in the 6-inch (DN 150) Type 1098-EGR-6354

with the size 30 actuator. This construction uses the

Type 1806H relief valve (with a setting of 40 psi

(2,8 bar)) to relieve excess loading pressure and does not

interfere with the normal operation of the regulator.

Installation and Startup

!

WARNING

Personal injury, equipment damage, or

leakage due to escaping accumulated

gas or bursting of pressure-containing

parts may result if this regulator is

overpressured or is installed where

service conditions could exceed the limits

on the appropriate nameplate, or where

conditions exceed any ratings of the

adjacent piping or piping connections.

To avoid such injury or damage, provide

pressure-relieving or pressure-limiting

devices to prevent service conditions from

exceeding those limits.

Additionally, physical damage to the

regulator may result in personal injury

and property damage due to escaping

accumulated gas. To avoid such injury

and damage, install the regulator in a

safe location.

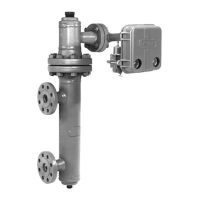

Standard Single-Pilot Regulator

(Figure 3)

Installations

A Type 1098-EGR or 1098H-EGR regulator bleeds

no gas to the atmosphere, making it suitable for

installation in pits or other enclosed locations without

Loading...

Loading...