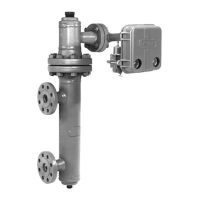

Types 1098-EGR and 1098H-EGR

16

Replacing Travel Indicator Assembly

The Types 1098-EGR and 1098H-EGR travel indicator

assemblies now incorporate a redesigned O-ring

retainer (key 6), Polytetrauoroethylene (PTFE)

backup rings (key 36), and an additional indicator

tting (key 35).

When performing maintenance on the original

Type 1098-EGR or 1098H-EGR body ange,

travel indicator replacement is recommended. The

redesigned travel indicator assembly is incorporated

into all Quick-Change Trim kits (e.g. 25A3170X012)

and on the Travel Indicator Kits (see table by size).

The elastomer repair kits contain the components for

the redesigned travel indicator assembly.

1. Remove the travel indicator assembly by

removing lower indicator tting (key 5) from the

body ange (key 2).

2. Coat the threads of the lower indicator tting

(key 5) with a good grade of general-purpose grease.

3. Install travel indicator assembly (10C1212), torque

to 40-inch-pounds.

4. Check indicator zeroing by unscrewing the

indicator protector (key 19) and seeing if the

ange of the indicator nut (key 22) lines up evenly

with the bottom marking on the indicator scale

(key 18). If not, remove the indicator scale

and separate the indicator nut and hex nut

(key 8). Hold the indicator scale against the

indicator tting (key 5) with the scale base

resting against the shoulder of the tting, and turn

the indicator nut until its ange is aligned with

the bottom scale marking. Then lock both nuts

against each other, and install the indicator scale

and protector.

Replacing Trim Parts

Perform this procedure when inspecting, cleaning, or

replacing individual trim package parts. Key numbers

are referenced in Figures 12 and 13.

Note

O-ring, travel indicator parts, or

optional travel stop (key 32) in step 1

can be gained without removing the

1. Remove the indicator tting (key 5) and attached

parts. Proceed to step 5 if only maintenance on

the tting or attached parts is performed.

2. Remove the cap screws (key 3) on a cast iron

body or remove the hex nuts (key 29, not shown)

on a steel body, and pry the body ange loose

from the valve body (key 1).

3. Use the valve body as a holding xture if desired.

Flip the body ange over, and anchor it on the

valve body as shown in Figure 10, removing the

pipe plug (key 31) rst if necessary.

4. To gain access to the port seal (key 12), upper seal

(key 15), or valve plug part, unscrew the seat ring

(key 13) from the cage (key 11) and the cage from

the body ange. For leverage, a wrench handle

or similar tool may be inserted into the seat

ring slots (Figure 10) and a strap wrench may be

wrapped around a standard or a Whisper Trim

TM

cage, or a soft bar may be inserted through the

windows of a standard cage. To remove the piston

ring (key 14) and/or plug O-ring (key 20), remove

the valve plug (key 16) from the body ange, insert

a screwdriver into the precut fold over area of

the piston ring, and unfold the piston ring. Proceed

to step 6 if no further maintenance is necessary.

5. To replace the body ange or gain access to the

spring, indicator stem (key 10), stem O-ring

(key 7), spring seat (key 28), E-ring (key 23),

or optional travel stop, remove the indicator

protector (key 19) and indicator scale (key 18).

Since some compression is left in the spring,

carefully remove the anged nut (key 22) and hex

nut (key 8). A screwdriver may be inserted

through the press-t bushing (key 6) to remove the

stem O-ring without removing the bushing. If

necessary, unscrew the travel stop (if used), and

unclip the E-ring from the indicator stem.

6. Replace and lubricate parts such as the gasket

(key 4) and cage O-ring (key 17) as necessary,

making sure that if the port and upper seals were

removed they are installed in their retaining slots

with the grooved sides facing out. Also lubricate

SIZE, INCHES (DN) m)

1 (25) 75 to 95 (102 to 129)

2 (50) 55 to 70 (75 to 95)

3 (80) 100 to 130 (136 to 176)

4 (100) 160 to 210 (217 to 285)

6, 8 x 6, 12 x 6

(150, 200 x 150, 300 x 150)

375 to 425 (509 to 577)

Type EGR Cap Screw (key 3) Torque, FOOT-POUNDS (N•m)

Loading...

Loading...