SECTION 2 - OPERATION

page 2-8

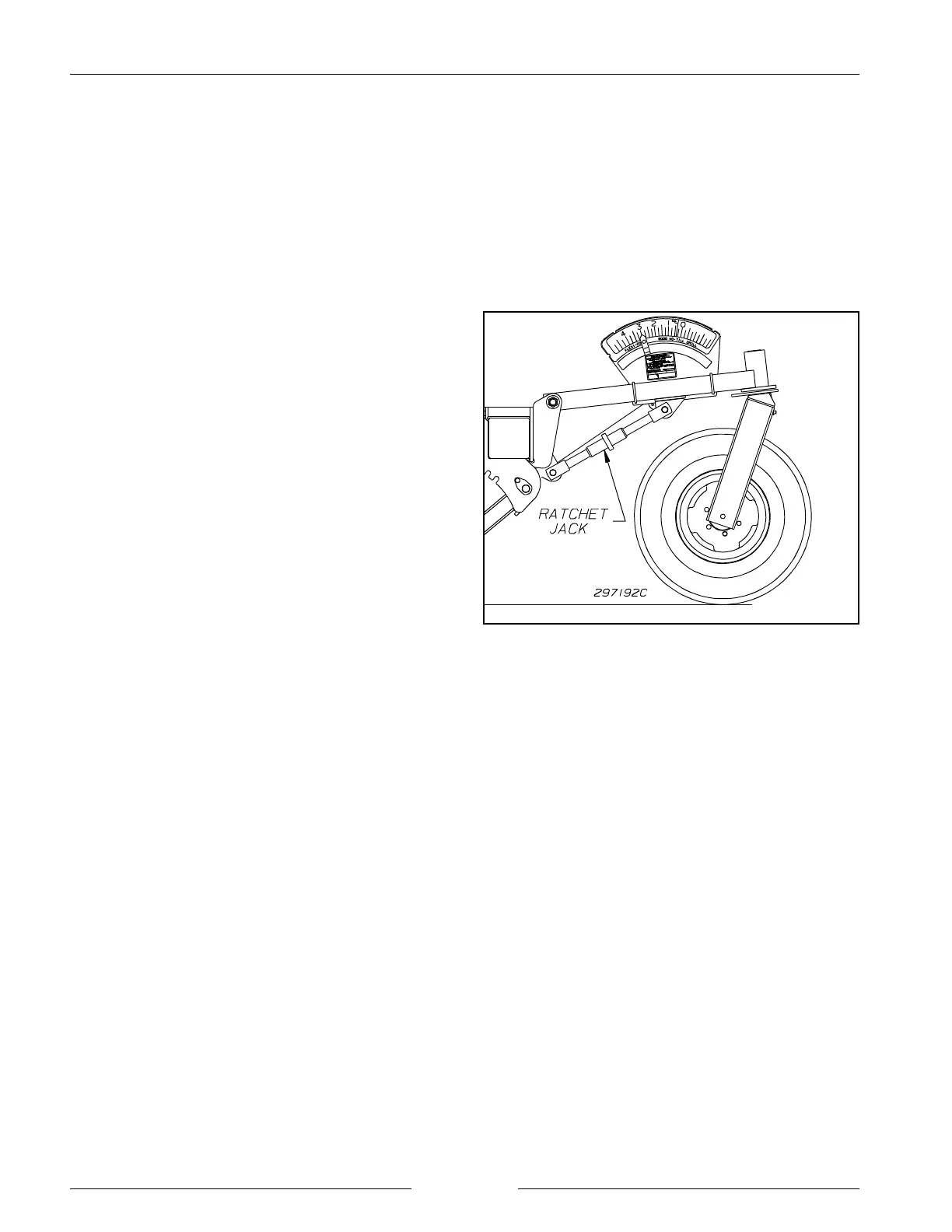

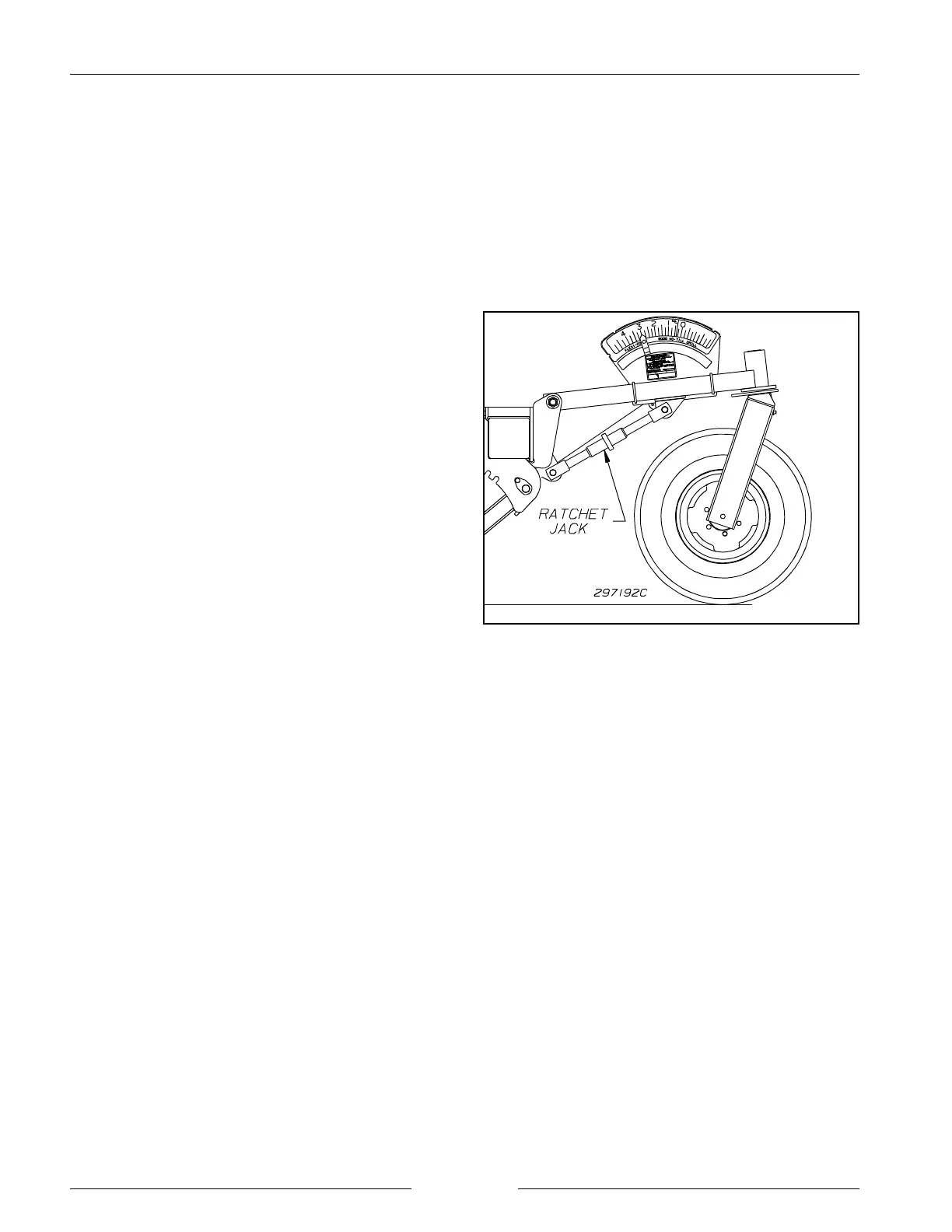

Ratchet Jack Adjustment

FIELD OPERATION

DEPTH CONTROL VALVE AND OPERATING DEPTH ADJUSTMENTS

Before adjusting the drill for operating depth make sure that the machine has been leveled and that the tires have the correct

operating pressure.

IMPORTANT: Never adjust the ratchet jacks when weight is on the gauge wheels. Failure to do so may

damage to the machine

1. Once the drill has been leveled (refer to the

Adjustments Section) the depth adjustment is

performed by adjusting the ratchet jacks on the front

gauge wheels. The center gauge wheel is linked to the

depth stop valve on the depth cylinder via a cable,

pulley linkage. As the machine is lowered the depth

cylinder pin moves toward the depth stop tab. Once

contact is made, the depth stop tab activates another

tab that closes the depth stop valve, stopping the frame

at the set operating height.

2. To set the operating depth, activate the depth control

hydraulic circuit to raise the implement to maximum

height.

3. Adjust the ratchet jacks to reference the actual seed

depth. (If a seeding depth of three inches is desired,

set the scale to 3). Be sure all ratchet jacks line up

with the same reference number on the scale. This will

be a starting point but will be affected by soil

conditions. In firm conditions the gauge reading will

show the seeding depth with the greatest accuracy.

NOTE: The indicator on the gauge wheel will shift

when weight is on the gauge wheels. This

shifting is normal and has been taken into

account during the initial leveling procedure.

Loading...

Loading...