SECTION 3 - MAINTENANCE

page 3-9

DANGER!

Tire Changing Procedure

CHANGING TIRES

To prevent personal injury when changing tires on

the implement, always block raised section. Be

sure section is stable before proceeding. Never

rely on a jack or hydraulic device to support raised

implement

The tires on the center section or the air drill are difficult

to change if the correct procedure is not followed. Refer

to the following instructions when changing tires. Note

that center section tires can be changed while the

machine is in transport position, however if at all

possible lower the unit into field position before

changing center section tires.

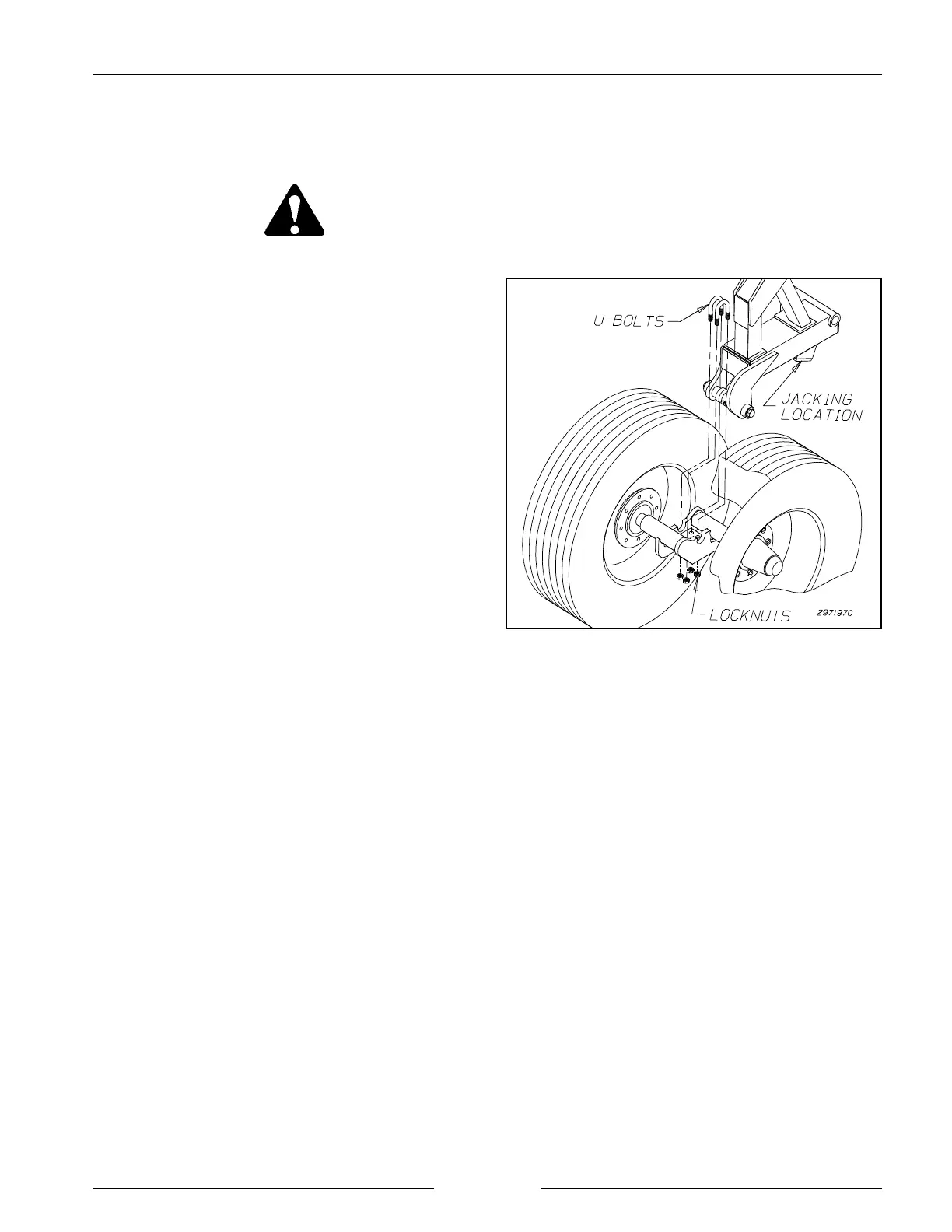

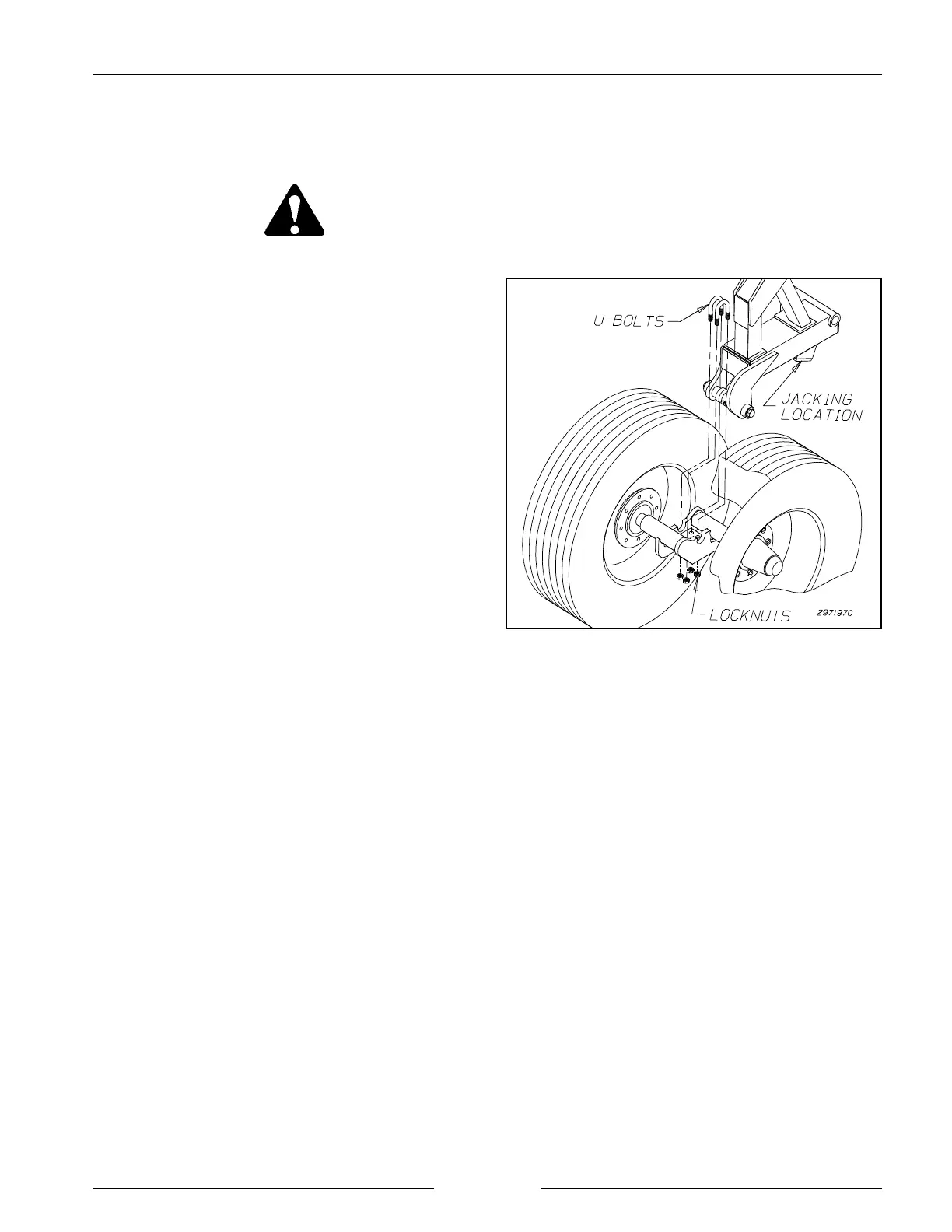

1. To ensure safety when jacking the unit, each wheel

standard is equipped with a jack stand mount. Using

a minimum of a 10 ton hydraulic jack and the

necessary blocking, jack the implement until the

weight is relieved from the walking axle. Refer to the

figure for the for jack stand mount location.

2. If any wing tire or center section outside tires are being

changed, remove the wheel bolts and replace the tire.

If any of the center section inside tires are being

changed, the walking axle must be separated from the

wheel standard before the tire can be removed. To

separate the walking axle remove the 5/8" x 1 13/16"

round u-bolts as shown.

3. Manoeuver the wheels and walking axle out from

under the unit. Change the tire.

4. Reposition the wheels and walking axle and bolt in

place. Replace the 5/8" locknuts with new locknuts.

Be sure to use the identical type of locknuts that were

removed from the machine (i.e., one way locknuts

only). Torque the nuts to 217 N-m (160 lbf-ft).

Loading...

Loading...