SECTION 3 - MAINTENANCE

page 3-7

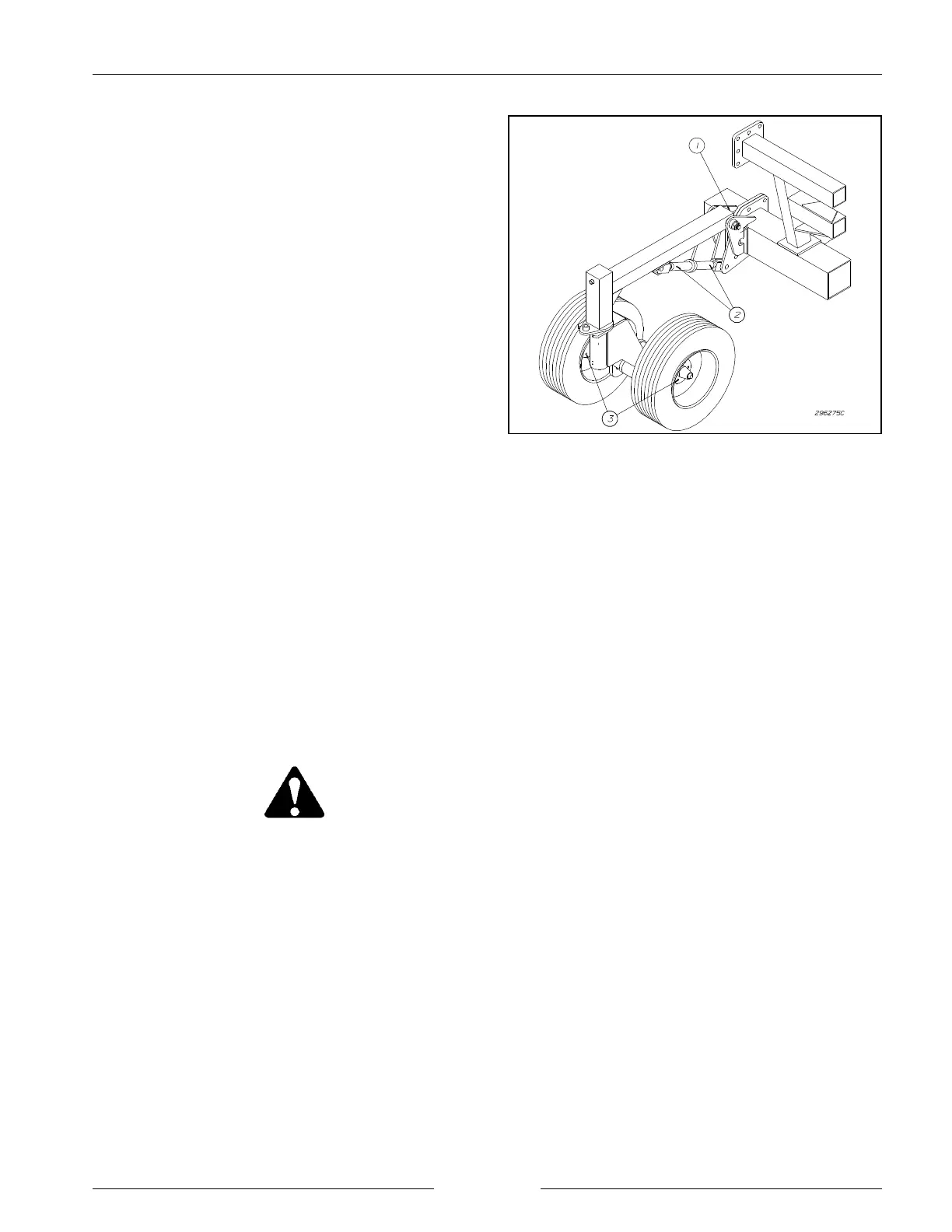

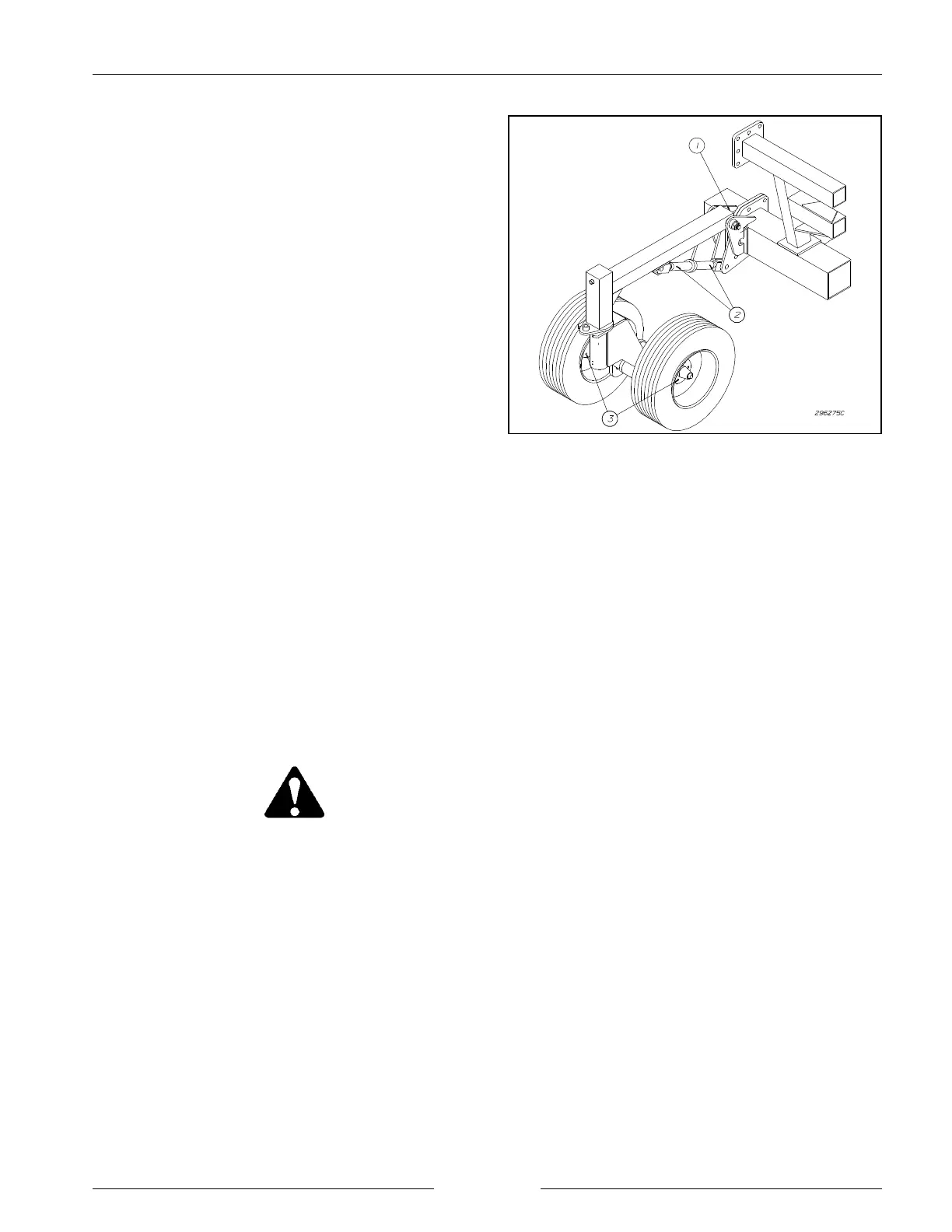

Grease Gauge Wheel and Ratchet Jacks

DANGER!

2. Grease the gauge wheel pivot bushings (1); 1 grease

zerk per gauge wheel (3 gauge wheels per unit).

3. Grease the ratchet jacks (2) located on each gauge

wheel assembly; 2 grease zerks per ratchet jack (3

ratchet jacks per unit).

4. Grease all wheel hubs (3) and inspect for looseness.

5. Grease the transport lock pivots located on the front

bar of the center section; 1 grease zerk per transport

lock (2 transport locks per unit).

BEFORE SEASONAL OPERATION OR BEFORE STORAGE

1. Perform or check items listed under daily and weekly

maintenance.

2. Inspect the implement. Be sure all components are

ready for the field. Check the frame for any signs of

structural cracks.

3. When placing the implement in storage for more than

one month, coat all exposed hydraulic ram surfaces

with a thick oil to protect them from the elements.

4. Check the implement, including openers, for loose

bolts and tighten.

To avoid personal injury or death, use utmost

caution when adjusting the opener assemblies

since the trip spring is in compression. Do not

attempt to remove the spring from the tension link

assembly. This unit was factory assembled and is

under extreme load; in no circumstance should

this assembly be field disassembled.

Loading...

Loading...