SECTION 5 - TROUBLESHOOTING

page 5-3

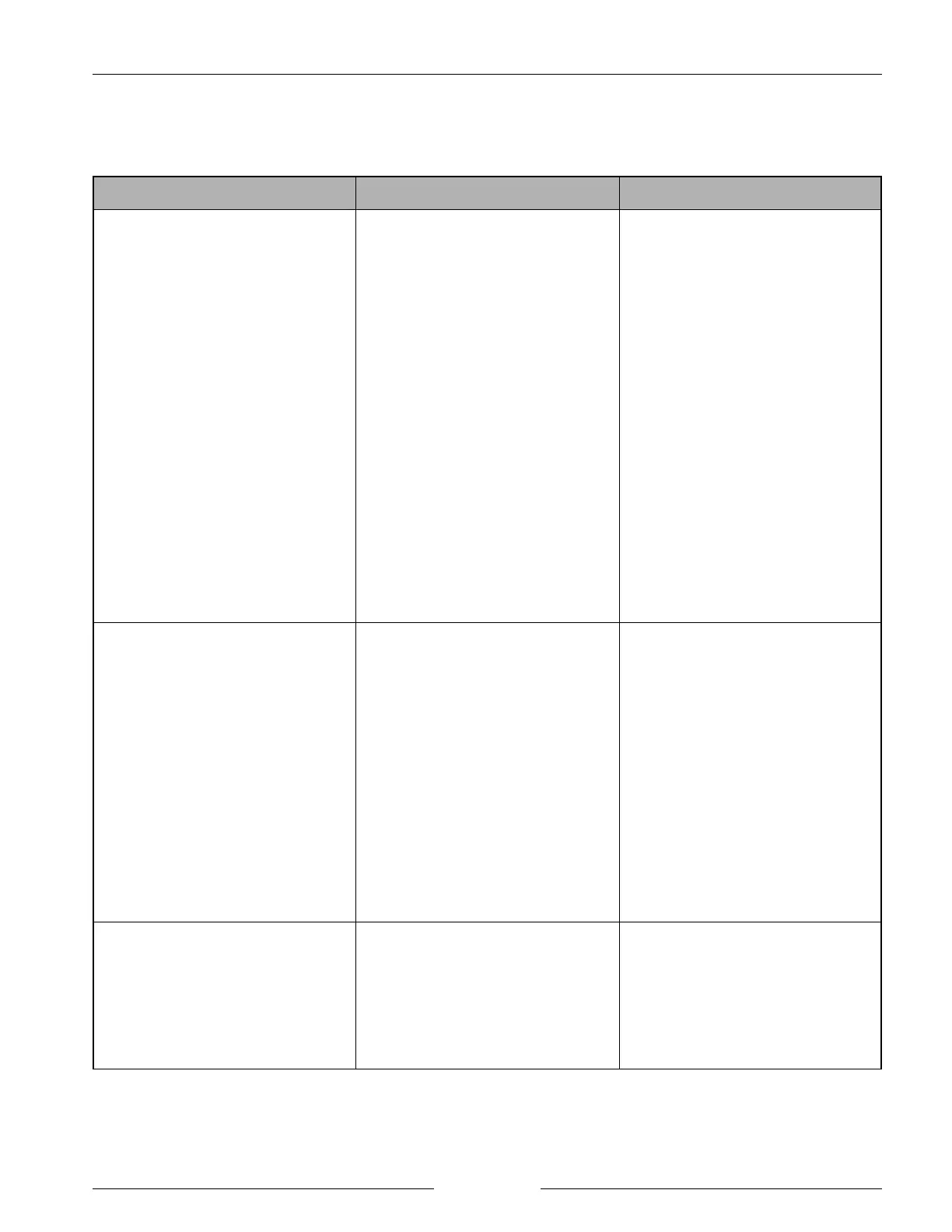

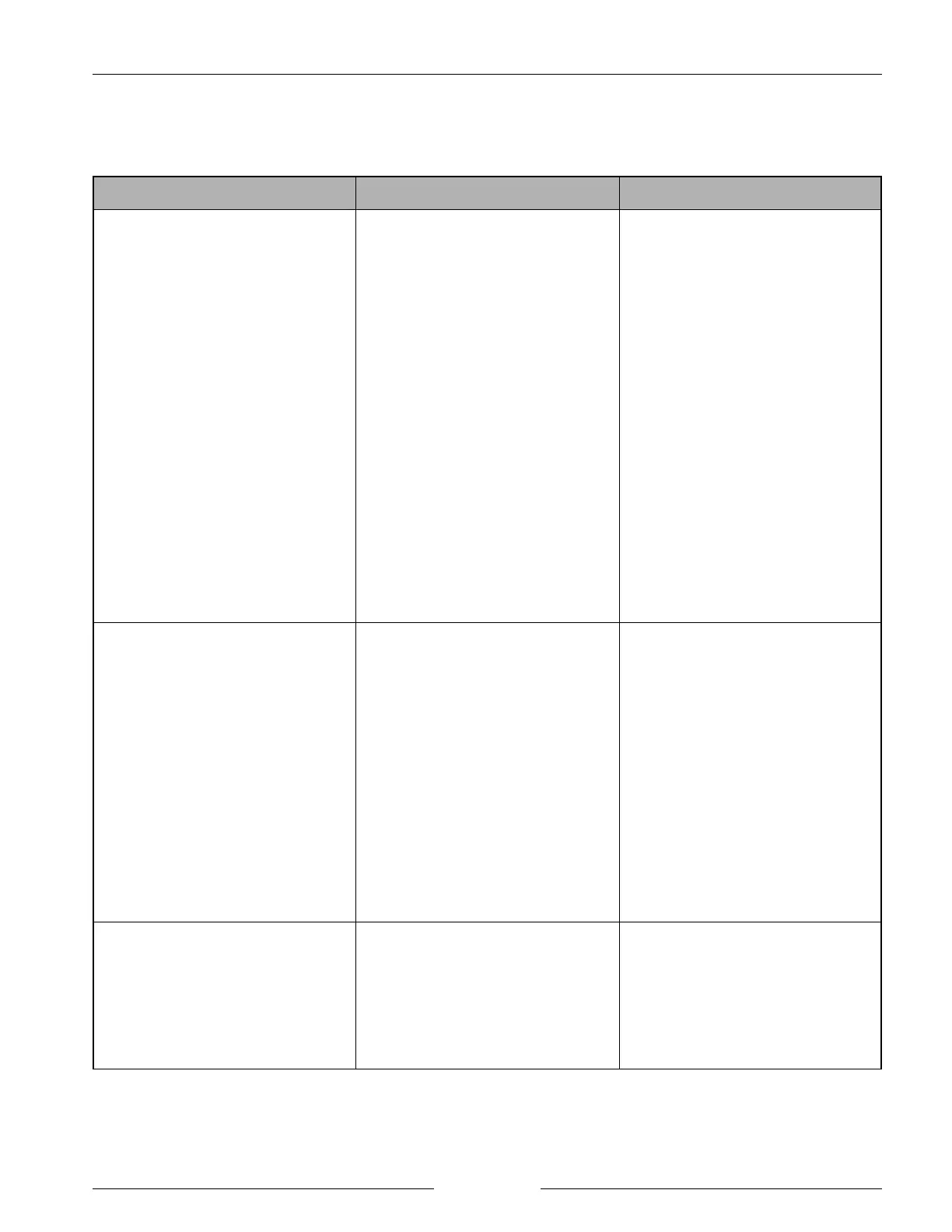

TROUBLESHOOTING TABLE

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

Uneven seeding depth across the

implement.

1. Implement is not leveled

properly side to side.

2. Implement not leveled properly

from front to rear.

3. Openers not set properly.

4. Tire pressures not to

specification.

5. Weight transfer due to draft

loads.

1. Level the implement side to

side.

2. Level the implement front to

rear.

3. Each opener must be set to the

same seeding depth to obtain

consistent seed depth. Refer

to the opener operator’s

manual.

4. Check tire pressures and

adjust as necessary.

5. Implement must ultimately be

leveled in actual field

conditions at actual working

depth.

Uneven seeding depth behind

tractor/air cart tires.

1. Soil compaction or deformation

due to tractor/air cart tires.

1. Adjust the seeding depth of the

openers in the affected zone to

obtain the required penetration.

Refer to the opener operator’s

manual.

or

Adjust the down pressure

setting of the opener’s in the

affected zone to obtain the

required penetration. Refer to

the opener operator’s manual.

Seeding depth changing during

operation.

1. Hydraulic system is failing due

to cylinder failure, depth stop

valve failure or tractor hydraulic

system failure.

1. Check for external oil leaks on

any of the hydraulic

components. Check for air

entrapped in the hydraulic

lines; this can be done by

bleeding a line to let air

escape.

Loading...

Loading...