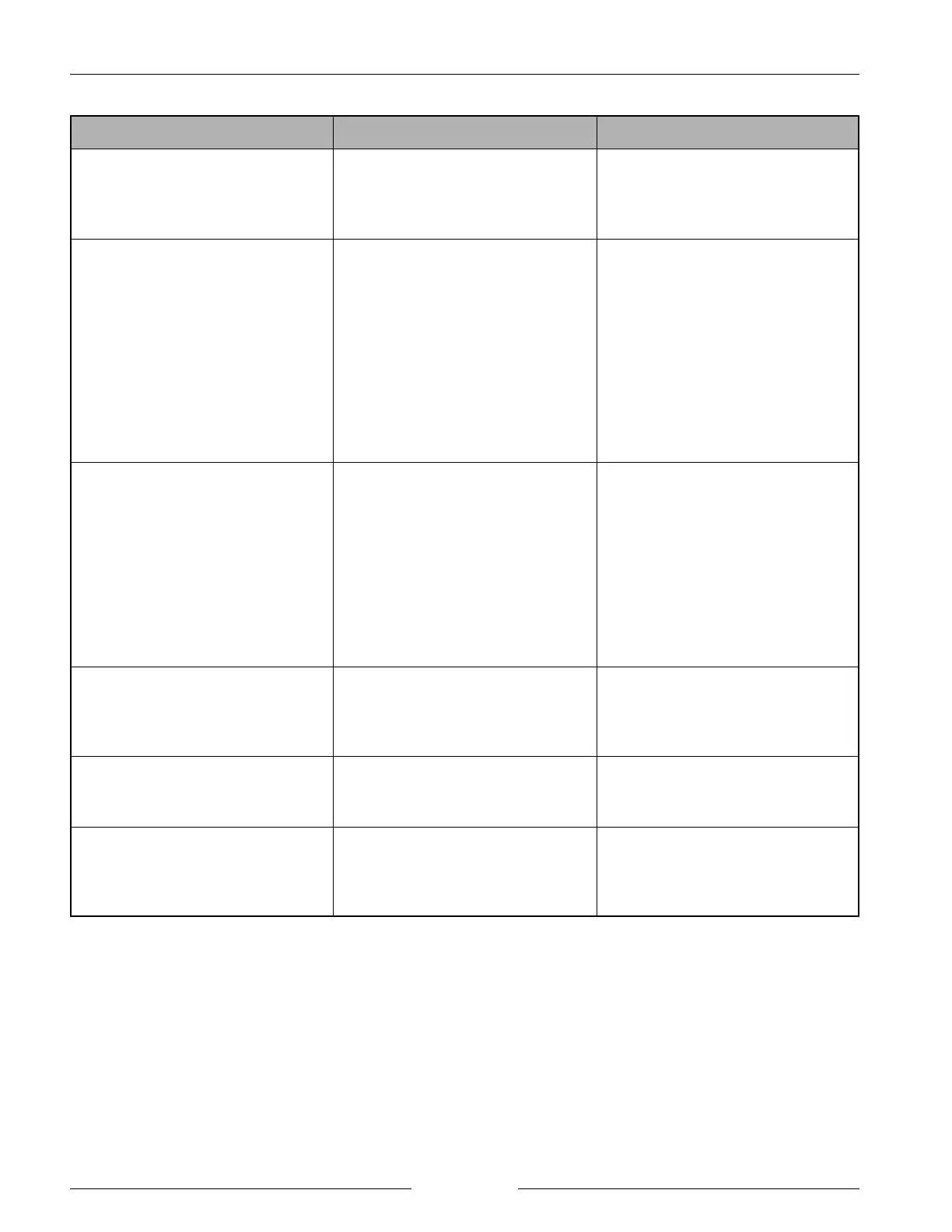

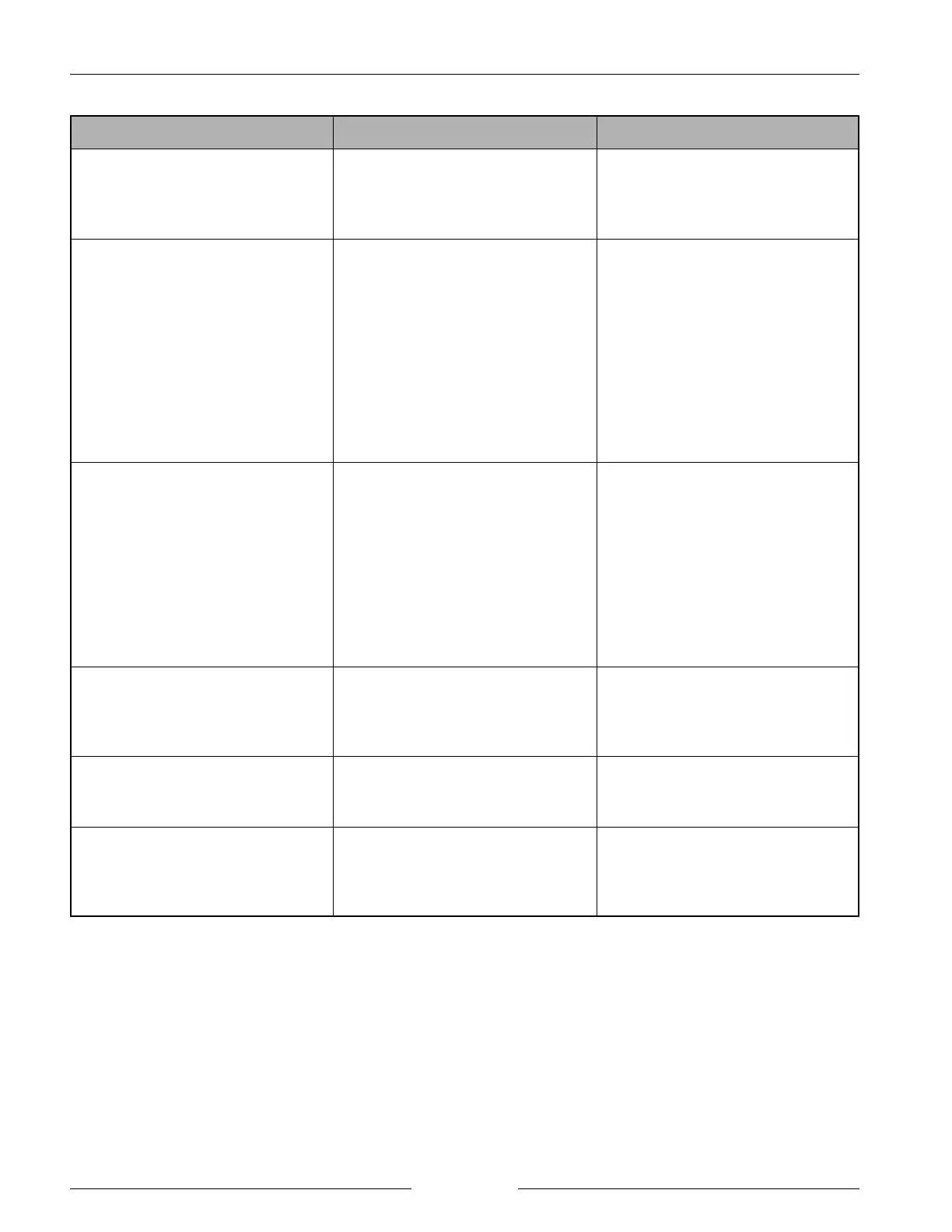

SECTION 5 - TROUBLESHOOTING

PROBLEM POSSIBLE CAUSES POSSIBLE SOLUTIONS

page 5-4

Implement not level in transport. 1. Hitch hydraulic cylinder base

not mounted in the proper lug

location.

1. Lug location dependent upon

tractor/air cart hitch height.

Mount cylinder base in the

proper lug location.

Seed depth varies from front to

back.

1. Back bar not at the same

working level as the front bar

2. Implement does not have

enough weight to penetrate soil

conditions.

3. Openers not set properly.

1. Check and re-calibrate the

front-to-back leveling

2. Extra weight may need to be

added to the rear bar.

Additional weight packages are

available; see your dealer.

3. Down pressure setting on the

opener needs to be adjusted.

Seed depth varies from center to

wing sections.

1. Wing section is not operating

at same level as the center

section

2. Wing section does not have

enough weight to penetrate soil

conditions.

1. Level the air drill.

2. .Extra weight may need to be

added to the rear bar of the

wing section. Additional weight

packages are available; see

your dealer.

Depth control safety lock

disengages.

1. Depth cylinder safety lock lever

not staying in the locked

position due to the pivot bolt

being loose.

1. Tighten pivot bolt. Be sure you

can still rotate the safety lock

lever by hand.

Front of implement droops in

transport.

1. Hitch cylinders creeping. 1. Hitch cylinder transport locks

should be installed when

transporting the implement.

Depth stop valve not operating. 1. Depth stop valve not operating

due to shear bolt failure.

1. Replace the nylon shear bolt in

the depth stop assembly with a

new 5/16" x 2" nylon shear

bolt.

Loading...

Loading...