Argus E25 MOD II - Operating Instructions

Correcting faults and disturbances

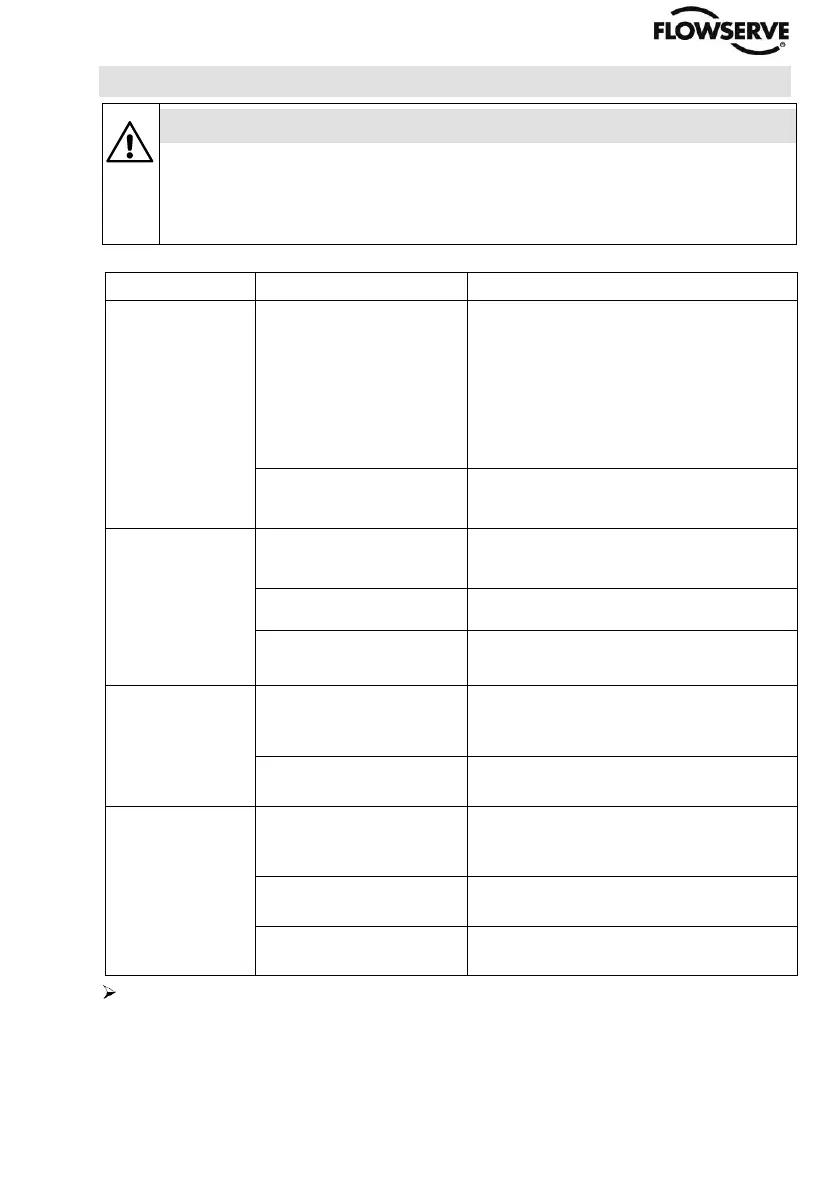

DANGER

A damaged unit can cause an accident that results in very serious injuries

or possibly death.

➢ Replace defective units immediately.

Electric motor not func-

tioning

Check the connection to the motor for

damage; make sure it is correctly con-

nected.

Check the PCB for signs of damage; if

you find damage, contact the manu-

facturer. Replace the limit switch

plate.

Have the motor replaced by an author-

ised person.

End-position limit

switches are incorrectly

set or connected.

Reset the end-position limit switches

correctly. See the chapter “Repairs”.

The unit has

excessive re-

sistance to

movement.

Current draw too

high.

Magnetic brake not

functioning correctly.

Check the connection to the brake for

damage; make sure it is correctly con-

nected.

Magnetic brake defec-

tive.

Have the brake replaced by an author-

ised person.

If the valve is damaged, contact the

manufacturer.

The actuator

does not

open/close fully.

End-position limit

switches are incorrectly

set.

Reset the end-position limit switches

correctly. See the chapter “Repairs”.

Please read the separate operating

instructions for the valve.

The unit

switches on, but

the operating

shaft does not

turn.

The operating shaft is

not correctly coupled.

Engage the operating shaft by gently

pulling and turning the shaft with the

engine off.

The timing belt has

failed.

Replace the timing belt. See the chap-

ter “Repairs”.

The unit’s reduction

gear has failed.

Replace the unit and contact the man-

ufacturer.

If you cannot correct the fault by following these instructions, please contact

the manufacturer.

Loading...

Loading...