The shaft gap, or distance between shaft ends

(DBSE), must be in accordance with the certified

General Arrangement Drawing and must be

measured with pump and driver shafts in the center

of their axial end float. Motor with sleeve bearings is

to be aligned with rotor at magnetic center.

Move driver to insure proper gap distance.

It is recommended that the pump hold-

down bolting be torqued before taking any alignment

measurements. This makes the pump the fixed

machine and the driver the movable machine. In

certain cases, however, it may be impractical to move

the driver; therefore, the pump may have to be

Bracket sag must be determined and included in the

and read indicator and register.

the sag is equal on both sides.

Before moving the equipment vertically, it is important

that the vertical thermal expansion be taken into

and/or driver instructions for

recommended cold vertical setting (if thermal

The shims between the motor feet and mounting

surface should be clean and dry. This is especially

critical for equipment that has been in service for

some time and need to be realigned. Water, dirt and

rust may change the height of the shim pack over a

period of time. Shims should be made large enough

to support the weight of the motor on its mounting

foot. Do not use many thin shims, as this may result

Move the equipment vertically by adding or removing

the calculated thickness of shims. Torque equipment

hold-down bolting to required values.

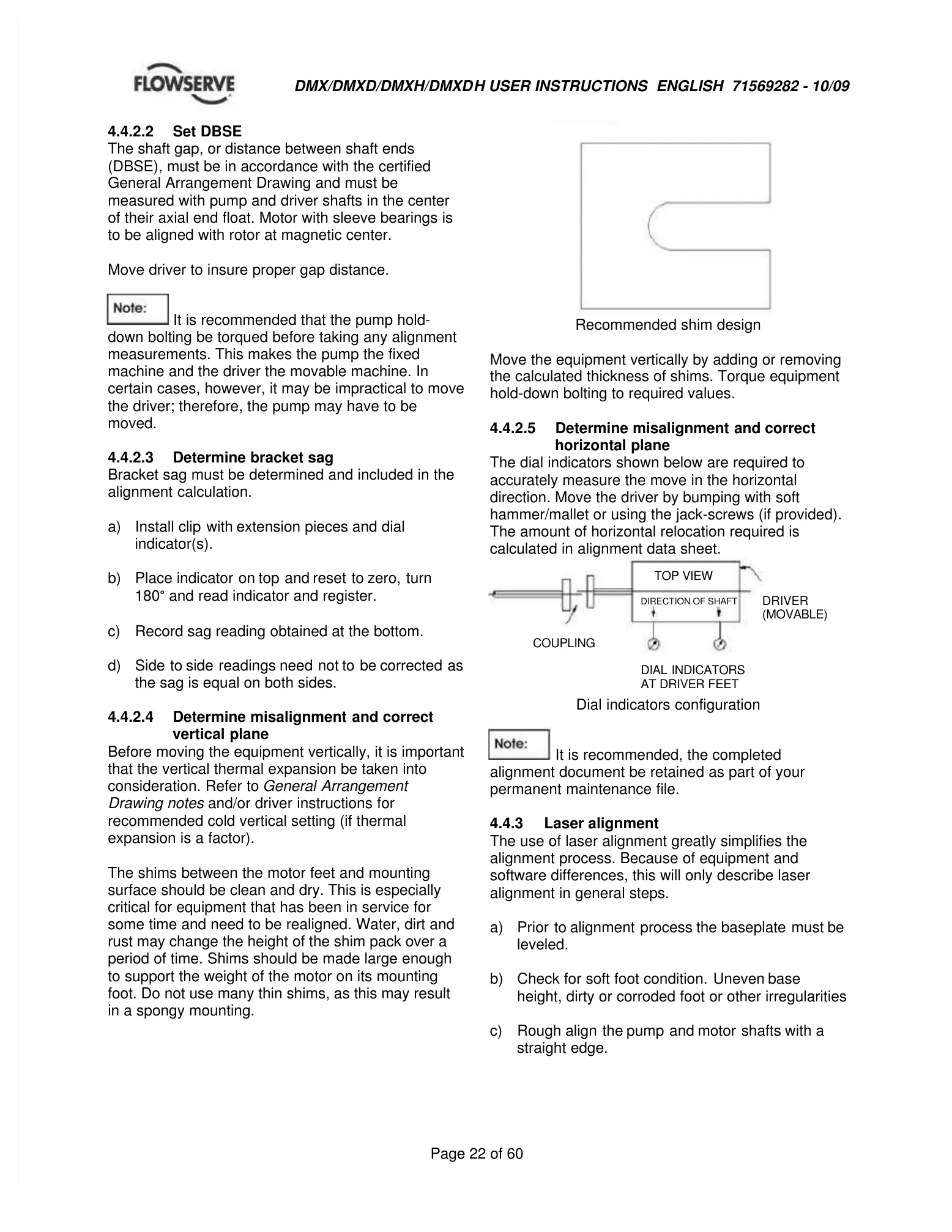

The dial indicators shown below are required to

accurately measure the move in the horizontal

direction. Move the driver by bumping with soft

hammer/mallet or using the jack-screws (if provided).

The amount of horizontal relocation required is

calculated in alignment data sheet.

Dial indicators configuration

It is recommended, the completed

alignment document be retained as part of your

permanent maintenance file.

The use of laser alignment greatly simplifies the

alignment process. Because of equipment and

software differences, this will only describe laser

alignment in general steps.

height, dirty or corroded foot or other irregularities

Loading...

Loading...