the laser target on the motor shaft.

and angular alignment per laser unit’s output.

Make the necessary corrections by adding or by

removing shims at the motor feet.

and angular alignment per the laser unit’s output

by using a soft mallet or adjusting screws.

The angular and offset coupling alignment must be

0.0254 mm (0.001 in.) TIR.

0.0762 mm (0.003 in.) TIR.

consult turbine manufacturer.)

instructions included in Section 8 of this manual.

Pump hold down bolts are to be torqued to the

proper value and dowel pins put in two diagonally

to expand with temperature away from coupling end

of pump. The units that come under this classification

must have the pump support feet dowelled to the

pedestal at the coupling end. This maintains the

coupling gap at the desired amount.

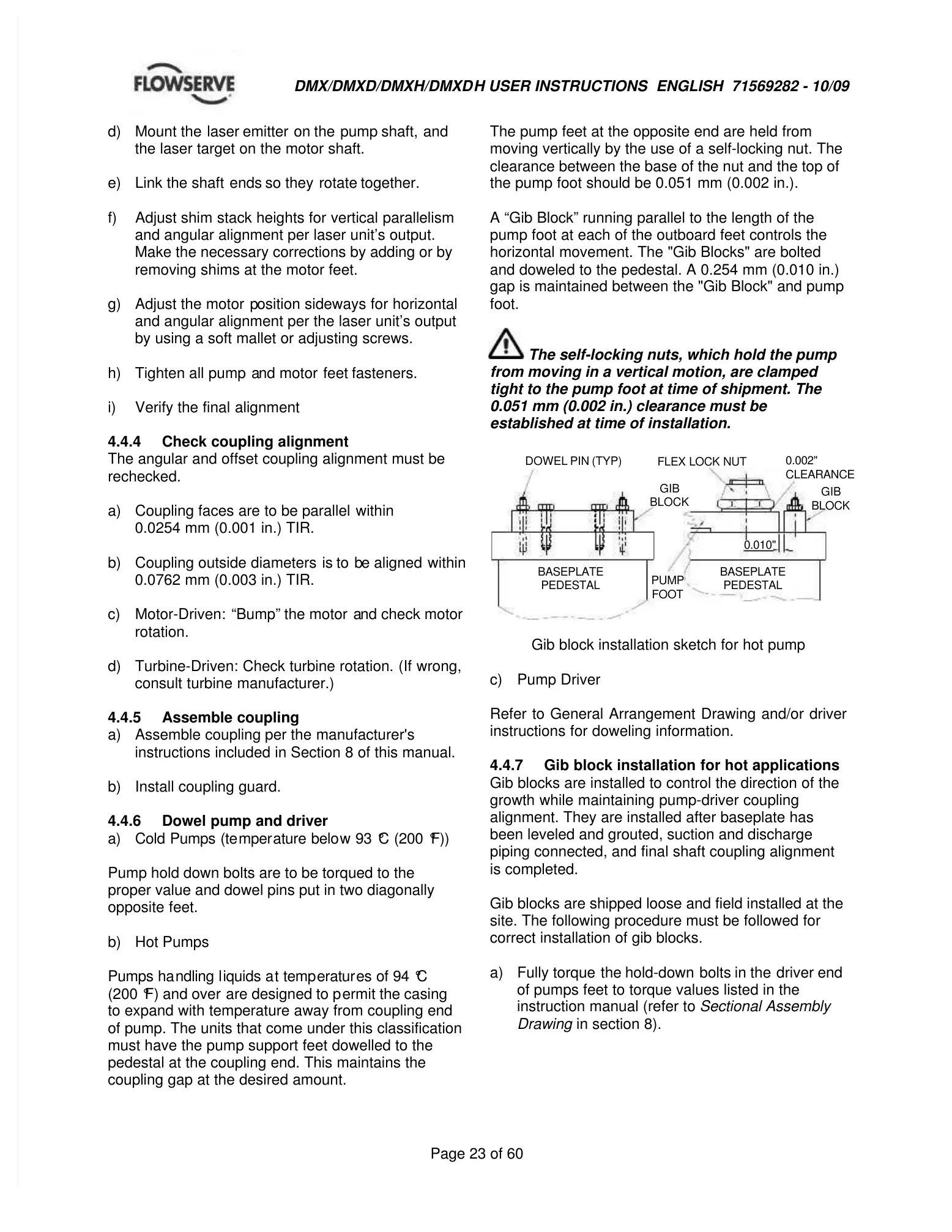

The pump feet at the opposite end are held from

moving vertically by the use of a self-locking nut. The

clearance between the base of the nut and the top of

the pump foot should be 0.051 mm (0.002 in.).

A “Gib Block” running parallel to the length of the

pump foot at each of the outboard feet controls the

horizontal movement. The "Gib Blocks" are bolted

and doweled to the pedestal. A 0.254 mm (0.010 in.)

gap is maintained between the "Gib Block" and pump

The self-locking nuts, which hold the pump

from moving in a vertical motion, are clamped

tight to the pump foot at time of shipment. The

0.051 mm (0.002 in.) clearance must be

established at time of installation.

Gib block installation sketch for hot pump

Refer to General Arrangement Drawing and/or driver

instructions for doweling information.

Gib blocks are installed to control the direction of the

growth while maintaining pump-driver coupling

alignment. They are installed after baseplate has

been leveled and grouted, suction and discharge

piping connected, and final shaft coupling alignment

Gib blocks are shipped loose and field installed at the

site. The following procedure must be followed for

correct installation of gib blocks.

of pumps feet to torque values listed in the

instruction manual (refer to

Loading...

Loading...