pressure does not fall below that required to prevent

should be installed on both sides of the strainer so

that the pressure drop across the strainer can be

engineer or system designer for the allowable

pressure differential across the strainer prior to

Pressure differential across

strainer and/or screen is typically no more than

the differential pressure

between the two gauges indicates that the strainer or

screen is becoming clogged with dirt and scale.

Before the pressure drop becomes so severe that

cavitation occurs, the pump should be shut down and

pump from damaging cavitation and loss of suction

need to be supplied by the plant engineer or system

settings to protect the pump from damaging

cavitation and loss of suction would be 5 psig

differential pressures across the strainer (screen).

The suction piping should be arranged such that the

ultimate strainer configuration (location) allows ready

The strainer may be fitted with a finer screen to filter

typically used for start-up operation, at reduced flow

suction strainers are normally removed after the

where continuous screening of suction flow is

desirable, and in open systems, 20-mesh screening

when using screens and suction strainers, it is

critical that pressure drop across the screen and/or

strainer be constantly monitored to ensure that the

pump suction pressure does not fall below that

required to prevent cavitation.

When dirt and scale have been removed from the

system, as indicated by no further change in pressure

drop across the strainer with time, the start-up

strainer may be removed or the screen may be

permanent strainer will be used during normal

operation, the pressure differential needs to be

monitored on a continuous basis.

If a permanent strainer is not used, the start-up

strainer needs to be temporarily reinstalled whenever

the system is opened up for repair or routine

remains in place, the differential pressure should be

monitored on a regular basis.

The pressure drop across the strainer

is a direct reduction in the NPSH available to the

limit the pump flow rate, particularly during start-up

devices should be installed to minimize the possibility

operator to obtain the allowable pressure drop across

the strainer for safe pump operation from the plant

engineer or system designer prior to operation of the

Refer to section entitled

shaft/coupling alignment

perform a coupling alignment check as outlined. This

check is recommended to insure the alignment has

not been disturbed during installing suction and

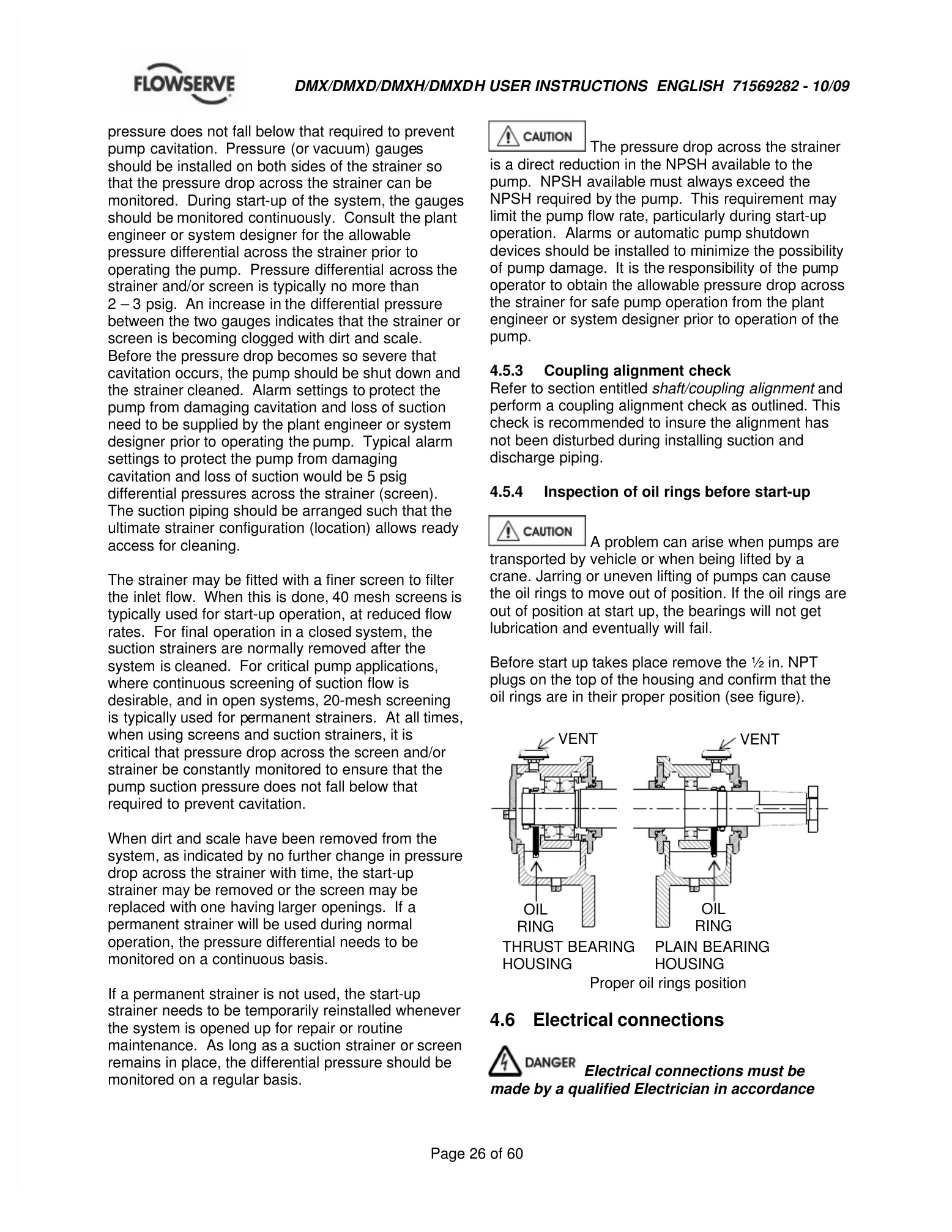

A problem can arise when pumps are

transported by vehicle or when being lifted by a

crane. Jarring or uneven lifting of pumps can cause

the oil rings to move out of position. If the oil rings are

out of position at start up, the bearings will not get

lubrication and eventually will fail.

Before start up takes place remove the ½ in. NPT

plugs on the top of the housing and confirm that the

oil rings are in their proper position (see figure).

Proper oil rings position

Electrical connections must be

made by a qualified Electrician in accordance

Loading...

Loading...